Taco® SKV

6

302-365, Effective: June 5, 2017

© 2017 Taco, Inc.

7.3 VFD Mounting to Wall

7.3.1 Lifting

• Check the weight of the unit to determine a safe lift-

ing method.

• Ensure that the lifting device is suitable for the task.

• If necessary, plan for a hoist, crane, or forklift with the

appropriate rating to move the unit.

• For lifting, use hoist rings on the unit, when provided.

7.3.2 Mounting

• Mount the unit vertically.

• The frequency converter allows side by side installa-

tion.

• Ensure that the strength of the mounting location will

support the unit weight.

• Mount the unit to a solid flat surface or to the optional

back plate to provide cooling airflow (see Figure 7-2

and Figure 7-3).

• Improper mounting can result in overheating and

reduced performance.

• Use the slotted mounting holes on the unit for wall

mounting, when provided.

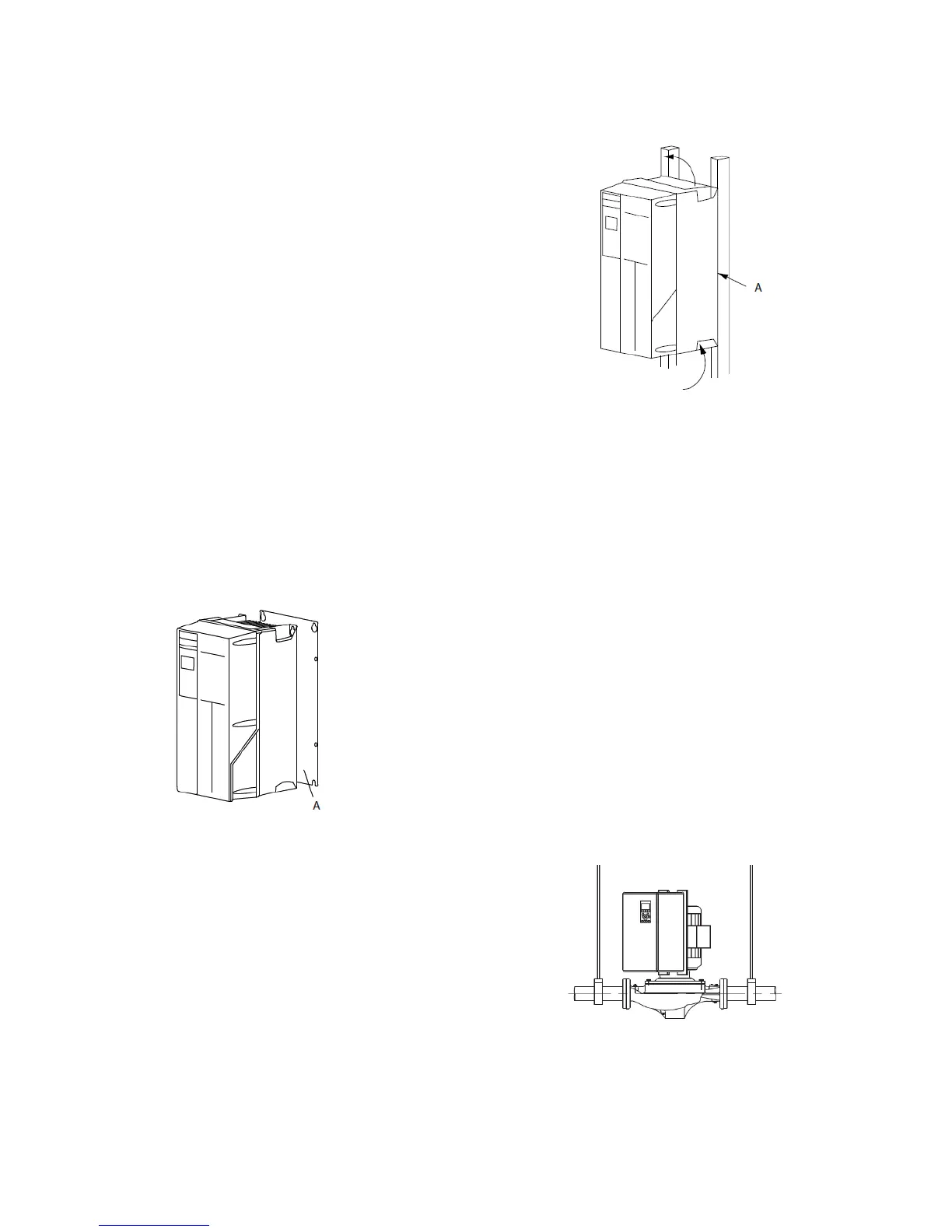

Figure 7-2: Proper Mounting with Back Plate

Item A is a back plate properly installed for required air-

flow to cool the unit.

Figure 7-3: Proper Mounting with Railings

NOTE: Back plate is required when mounted

on railings.

7.3.3 Tightening Torques

See “17.2 Connection Tightening Torques” on page 77

for proper tightening specifications.

7.4 Pump Piping – Detailed

In order to achieve the full added value of the Vertical In-

Line pump design, it is important that you ensure the

pump is affixed to the system piping by the pump flanges

and the pump and motor assembly is allowed to float

freely with the expansion and contraction of the piping

system. Should any vertical in-line pump use supports to

the structure, it is imperative that no pipe strain is

imposed on the pump flanges. Compliant mounts such

as springs or “waffle”-style isolation pads should be used

under the pipe supports if the pump is not truly pipe

mounted.

Various installation arrangements are detailed in the fig-

ures that follow.

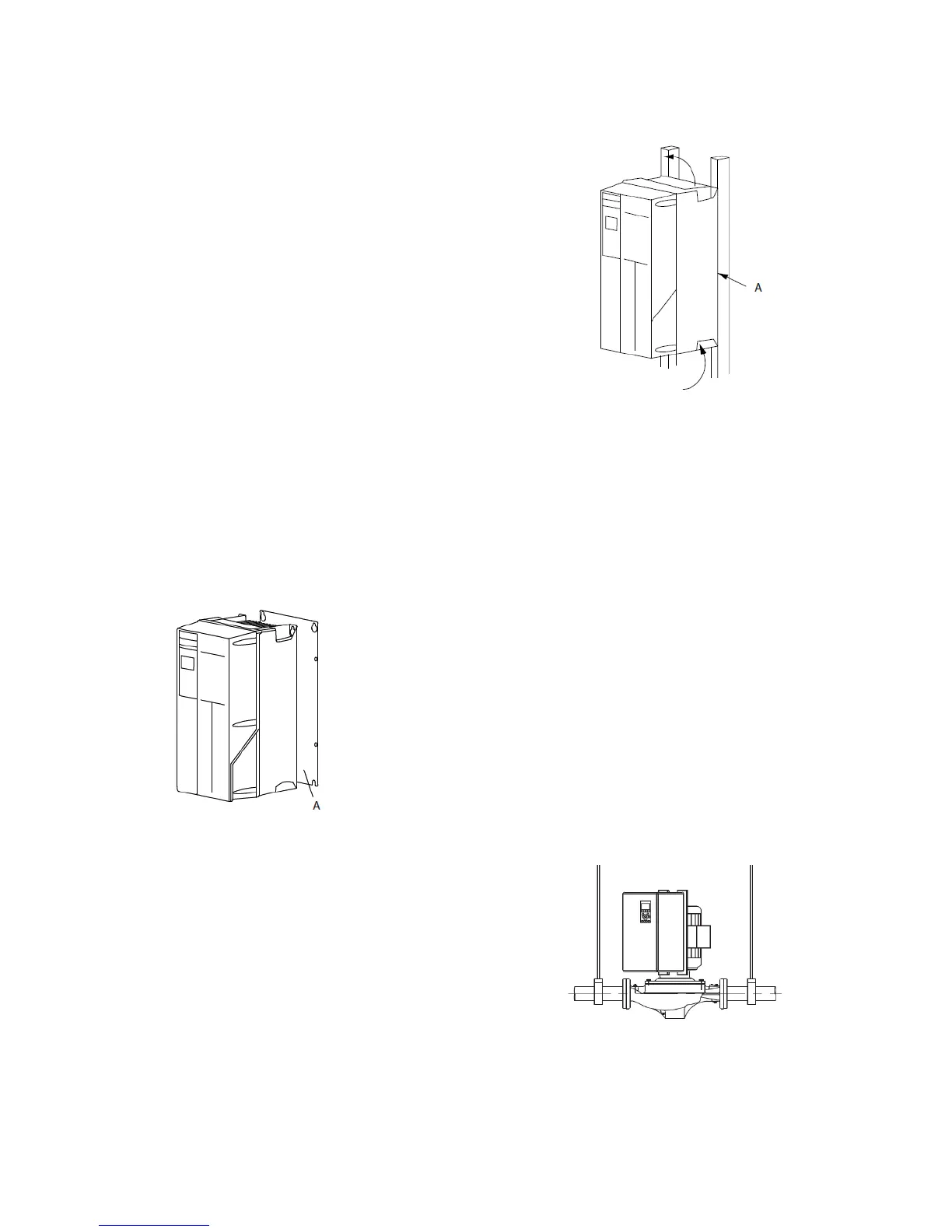

Figure 7-4: Hanger Supported, Pipe Mounted

NOTE: The pump should not be rigidly attached to the base/pad structure unless flexible couplings are used.

Loading...

Loading...