Taco® SKV

83

302-365, Effective: June 5, 2017

© 2017 Taco, Inc.

APPENDIX B: ON-SITE DRIVE MOUNTING TO WALL OR PUMP

Follow the steps below for on-site drive mounting to wall

or to pump.

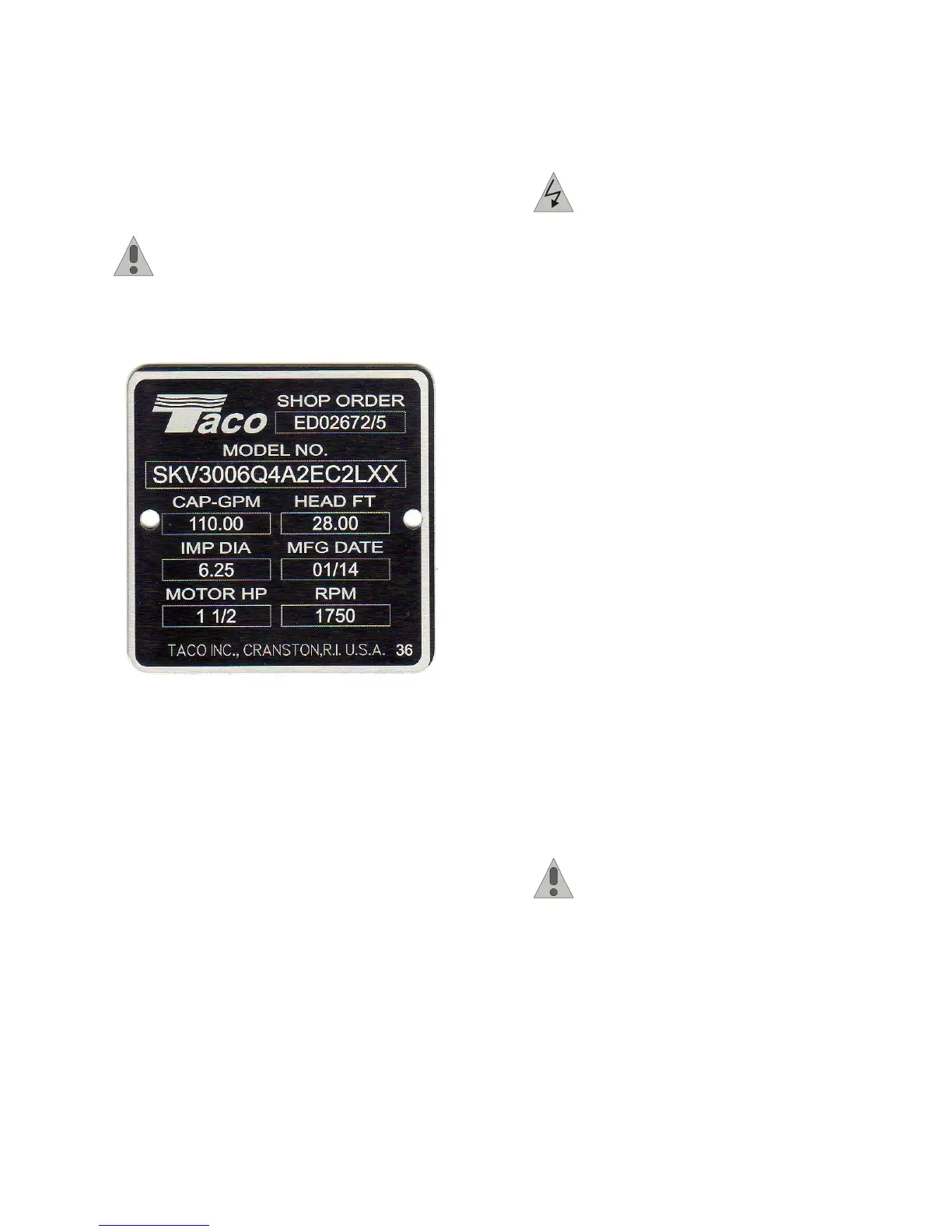

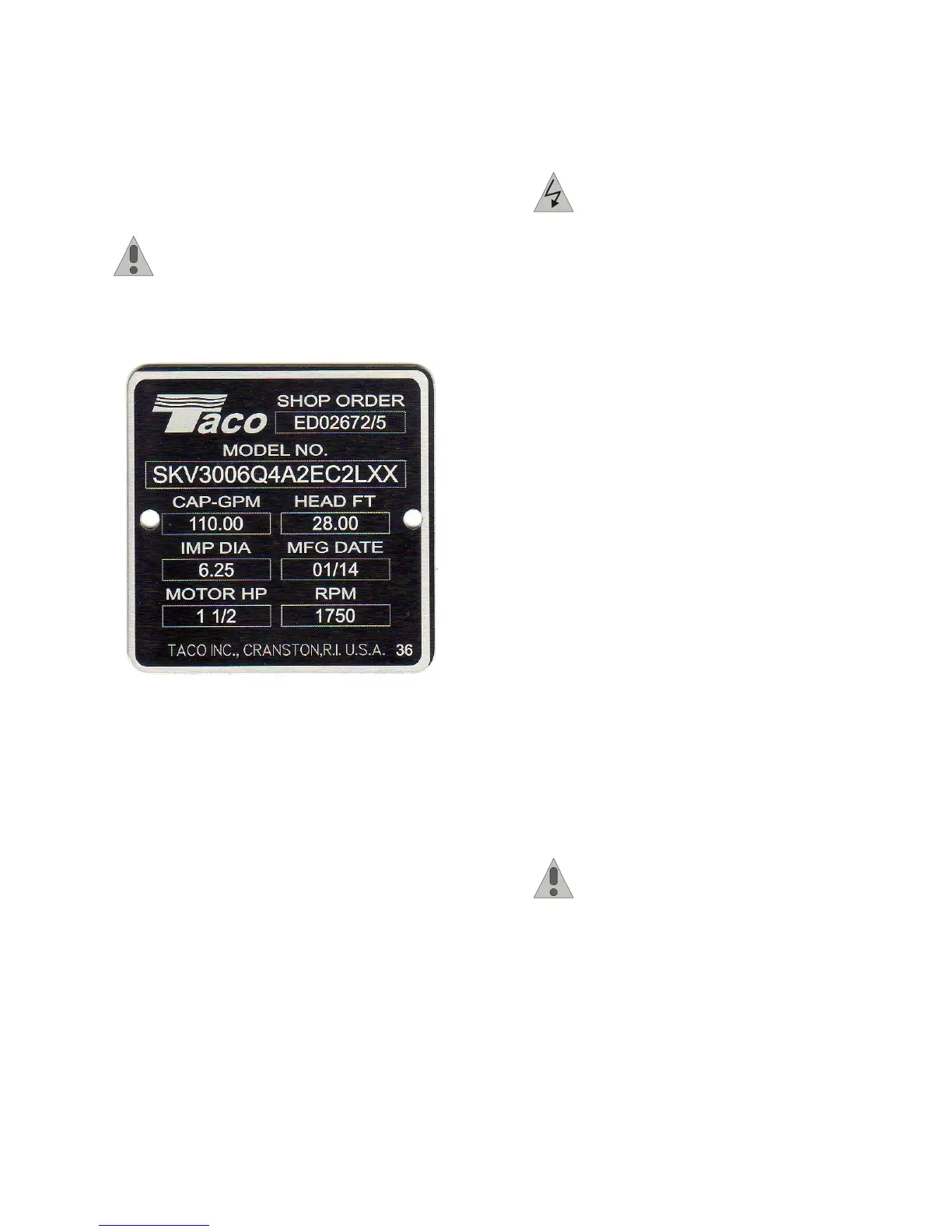

B.1 Match Pump and Drive Tags

IMPORTANT: Ensure the pump tag matches

the VFD tag. The pump and drive will have

identical tags as shown below.

Figure B-1: Example Tag

B.2 Mechanical Connections

For mechanical connections to pump, see section 7.2.

For mechanical connections to wall, see section 7.3.

B.3 Electric Code Compliance

Installation must be in compliance with national and local

electric codes.

For electrical connections see Section “8 Electrical Con-

nections” on page 9.

B.4 Before Start Safety Inspection

DANGER: HIGH VOLTAGE! If input and out-

put connections have been connected

improperly, there is potential for high voltage

on these terminals. If power leads for multi-

ple motors are improperly run in same con-

duit, there is potential for leakage current to

charge capacitors within the frequency con-

verter, even when disconnected from mains

input. For initial start up, make no assump-

tions about power components. Follow pre-

start procedures. Failure to follow pre-start

procedures could result in personal injury or

damage to equipment.

1.Input power to the unit must be OFF and locked

out. Do not rely on the frequency converter discon-

nect switches for input power isolation.

2.Verify that there is no voltage on input terminals L1

(91), L2 (92), and L3 (93), phase-to-phase and

phase-to-ground.

3.Verify that there is no voltage on output terminals

96 (U), 97 (V), and 98 (W), phase-to-phase and

phase-to-ground.

4.Confirm continuity of the motor by measuring ohm

values on U-V (96-97), V-W (97-98), and W-U (98-

96).

5.Check for proper grounding of the frequency con-

verter as well as the motor.

6.Inspect the frequency converter for loose connec-

tions on terminals.

7.Record the following motor-nameplate data: power,

voltage, frequency, full load current, and nominal

speed. These values are needed to program motor

nameplate data later.

8.Confirm that the supply voltage matches voltage of

frequency converter and motor.

CAUTION: Before applying power to the

unit, inspect the entire installation as detailed

in Table 23 on page 84. Check mark those

items when completed.

Loading...

Loading...