Taco® SKV

35

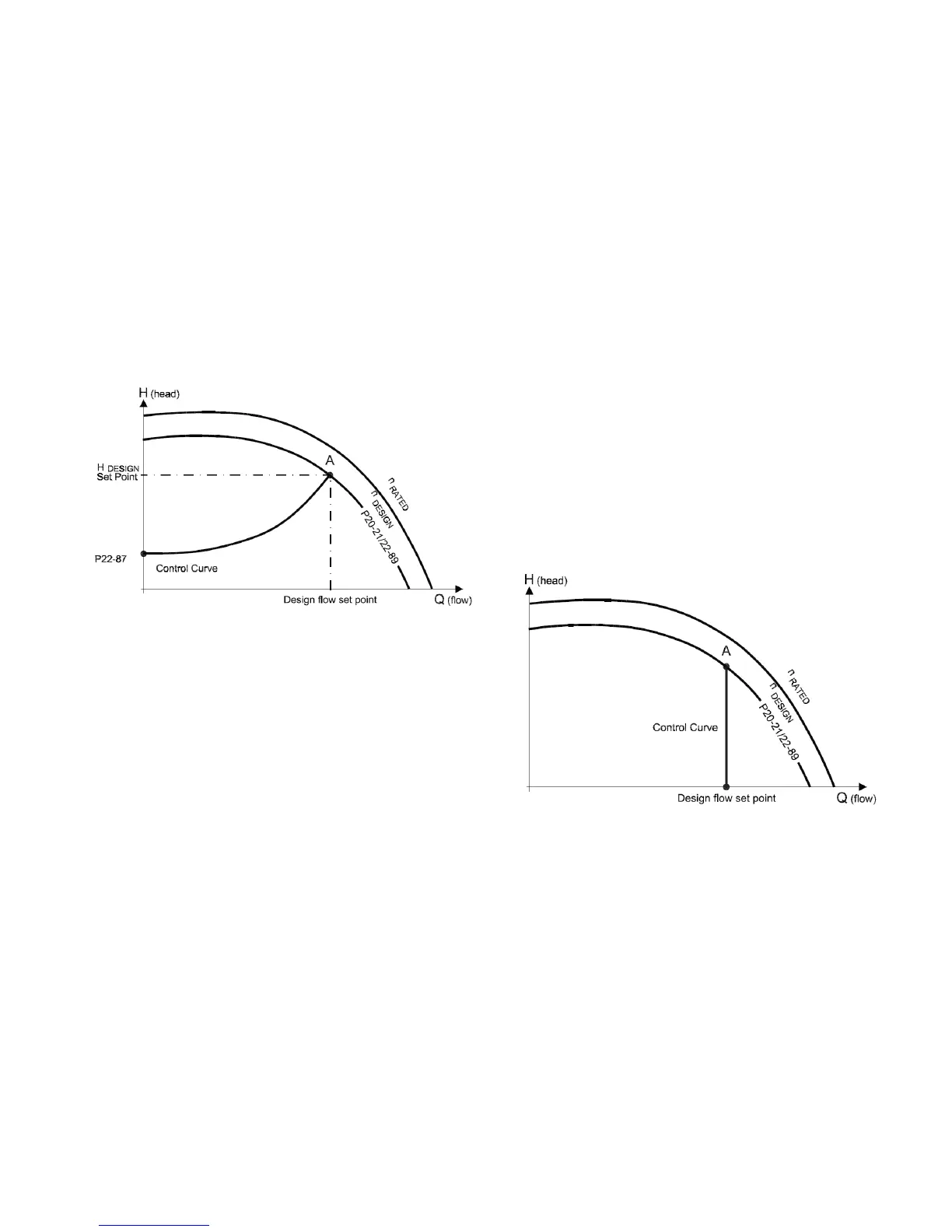

10.3 Variable Flow Control (Flow

Compensation)

Under Variable Flow Control (otherwise known as Flow

Compensation mode), the controller is set to control the

pump speed according to a ‘control curve’ between max

and min flow (see Figure 10-1 below). This mode should

be used for system distribution pumps. It is widely recog-

nised that fitting a differential pressure sensor at the most

remote load, across the supply piping and return piping

encompassing the valve & coil set, is the benchmark

scheme for energy efficiency.

Figure 10-1: Variable Flow Graph

Control

Head

SelfSensing pumps can replicate this control without the

need for the remote sensor. As the flow required by the

system is reduced, the pump automatically reduces the

head developed according to the pre-set control curve. In

other words, the pump follows the control curve.

It is often found that using a remote differential pressure

sensor to sense the pressure across a remote load could

theoretically result in loads close to the pump being

under-pumped. The situation would be where the load at

a loop extremity is satisfied and the control valve closes

while a load close to the pump needs full flow. The proba-

bility of this occuring is remote but it is possible. One

answer to this is to move the sensor closer to the pump

(two-thirds out in the system is a popular recommenda-

tion) although physically re-positioning the sensor at a

commissioning stage can be a costly exercise. With Self-

Sensing pump control it is possible to replicate the mov-

ing of a sensor by increasing the Control Head setting.

The design duty head and flow of the pump (provided at

time of order) is shown as point ‘A’ in Figure 10-1 below.

It is not always the case that the design duty point

required will fall on the maximum speed of the pump and

in the majority of cases (as shown in Figure 10-1 above)

it will be at a reduced speed.

302-365, Effective: June 5, 2017

© 2017 Taco, Inc.

The pump will be supplied with point ‘A’ set as the design

duty point provided at the time of order and the minimum

head at zero flow (Control Head) will be set as 40% of the

design head ‘H

DESIGN

’ as the default.

To change the control curve from the factory settings, fol-

low the startup procedures in “Appendix B: On-site Drive

Mounting to Wall or Pump” on page 83.

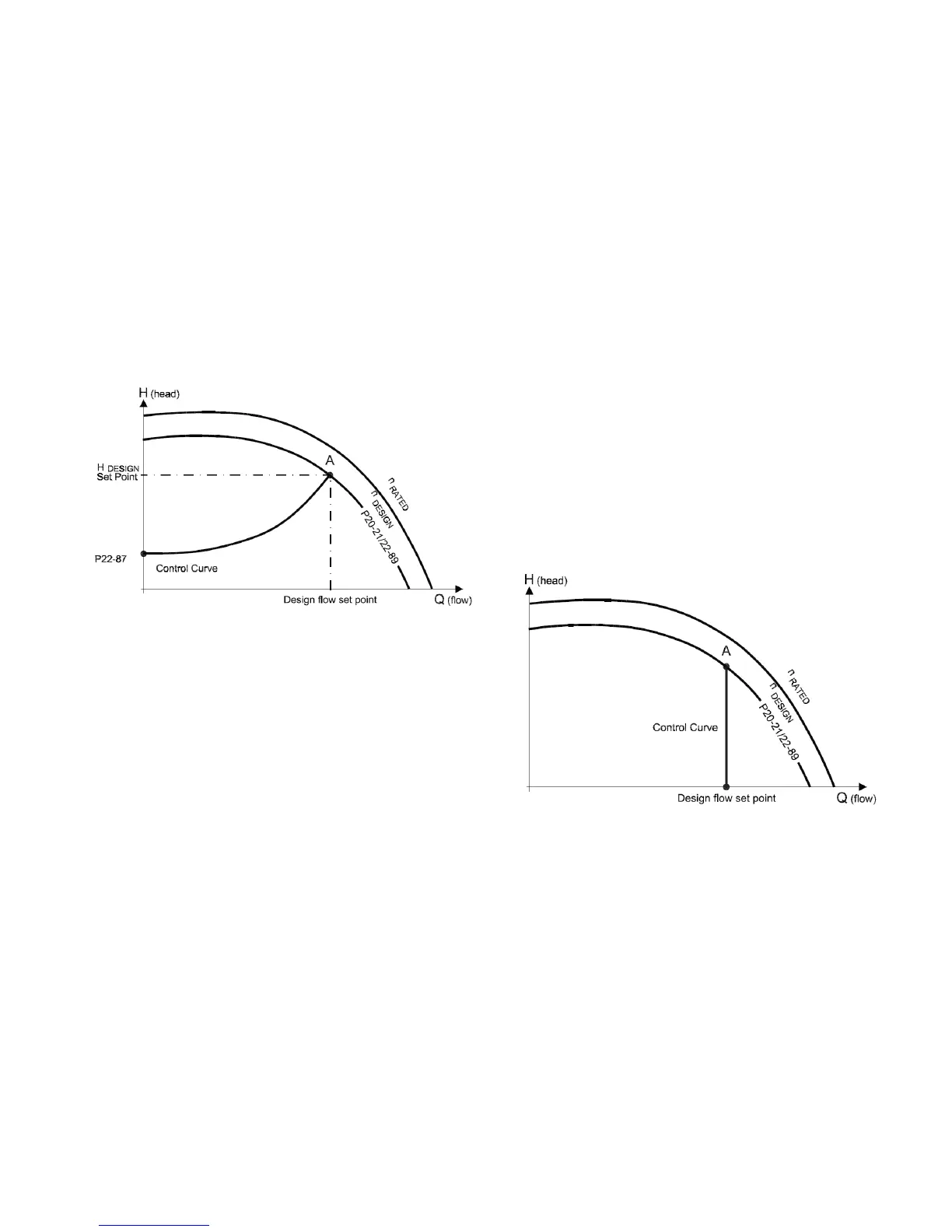

10.4 Constant Flow Control

SelfSensing pumps can be configured to maintain a con-

stant pump flow in a system. This control setting is ideal

for primary systems such as boiler or chiller loops that

require a constant flow.

10.4.1 For Central Plant, Constant Flow

Boiler/Chiller

If this pump was ordered for a central plant constant flow

boiler/chiller, you do not need to go through the balancing

procedures below. Ensure the drive is already in Set-up 3

(SelfSensing Constant Flow Mode) and is therefore

already self-balancing.

Figure 10-2: Constant Flow Graph

10.4.2 Settings for Constant Flow Control

To set the pump to constant flow mode and adjust the

flow rate, follow steps 1-12 in section 12.3.1.

Loading...

Loading...