Taco® SKV

23

302-365, Effective: June 5, 2017

© 2017 Taco, Inc.

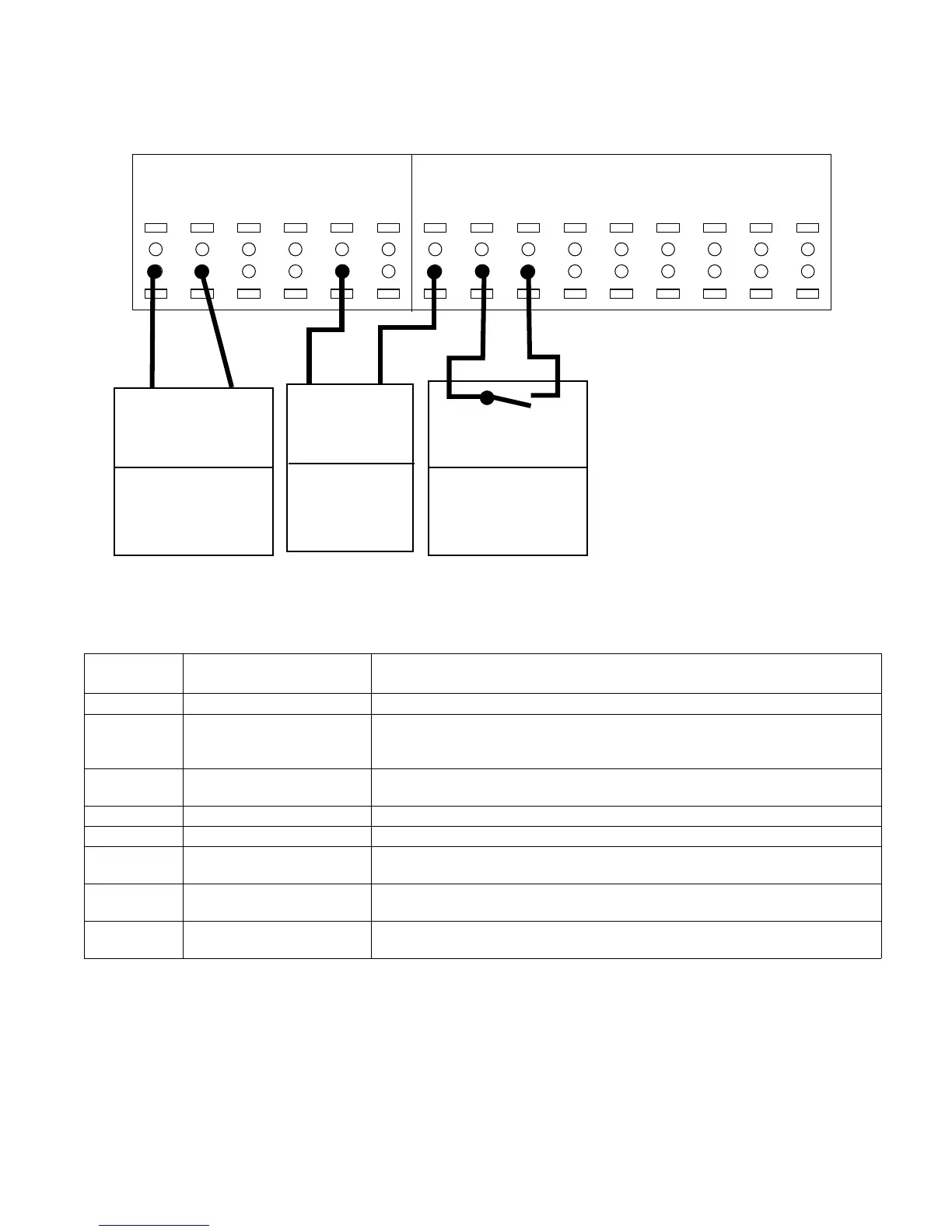

The following wiring scheme is used with Set-up 4 as shown in “10.1 SelfSensing Description” on page 34.

Figure 8-22: Terminal Wiring for 0–10V Sensor

39

COM

42

AOUT

50

+10V

53

A IN

55

COM

54

A IN

12

+24V

13

+24V

18

D IN

19

D IN

27

D IN

29

D IN

32

D IN

33

D IN

20

COM

I/O Analog I/O Digital

COM

AI

Unit Receiving

Analog Output

[6-50]

[137] Speed*

4-20 mA

* factory default

Starting/Stopping

Controller

[5-10]

[8] Start*

Start: Closed

* factory default

AO

+24V

0-10V

Transducer

[Group 6-]

[Group20-]

(See Table)

Set A54=U

(Optional)

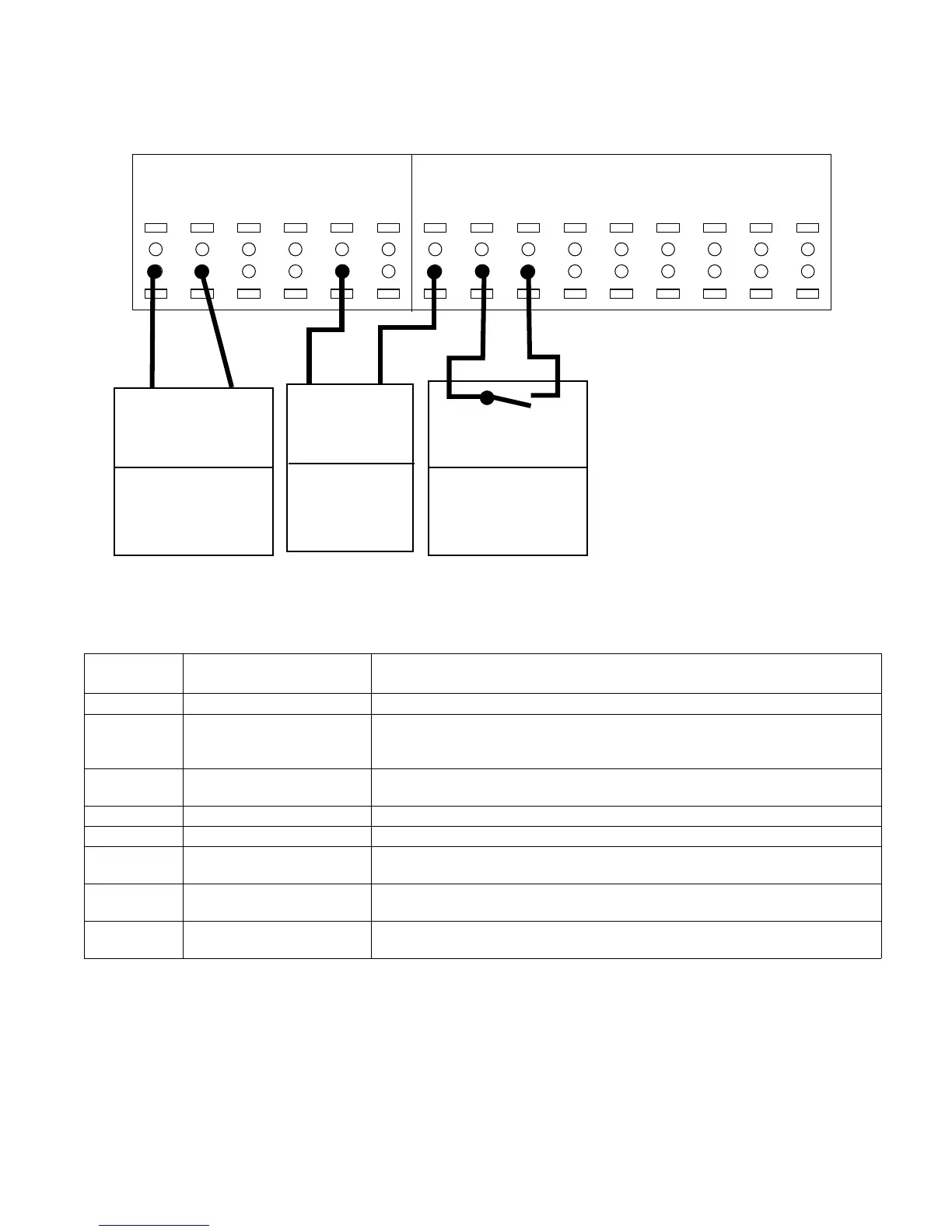

To configure the controller for closed loop control based on the input from an external transducer, use the following

parameters:

Table 4: Settings for a Wired Sensor for Input

* To use AI 53, set parameters 6–14, 6–15, 6–17 and set 20–00 to “Analog Input 53.”

To set up the controller with a transducer that is intended for external monitoring, as opposed to feedback to the con-

troller, set the following parameters:

Parameter

number

Description Set to

0–10 Active Set-up For wired pressure transducer, choose Set-up 4.

6-24* Terminal 54 Low Ref./Feedb.

Value

Minimum transducer input value. For example, for a 0–100 PSI transducer, set to

0. For live 0 function set feedback to 1V or 10 PSI. Note: Live 0 does not work if

minimum is set to 0.

6-25* Terminal 54 High Ref./Feedb.

Value

Maximum transducer input value. For example, for a 0–100 PSI transducer, set to

100.

6-27* Terminal 54 Live Zero Enabled

20-00 Feedback 1 Source Analog Input 54*

20-12 Reference/Feedback Set as appropriate for application. For example, set to PSI when using a pressure

transducer. The default value for this setting is PSI.

20–13 Minimum Reference/Feed-

back

Minimum transducer input value. For example, for a 0–100 PSI transducer, set to

0 PSI.

20–14 Maximum Reference/Feed-

back

Maximum transducer input value. For example, for a 100 PSI transducer, set to

100 PSI.

Loading...

Loading...