DC Inverter Air

shall be paid to that the saw dust cannot enter the pipeline);

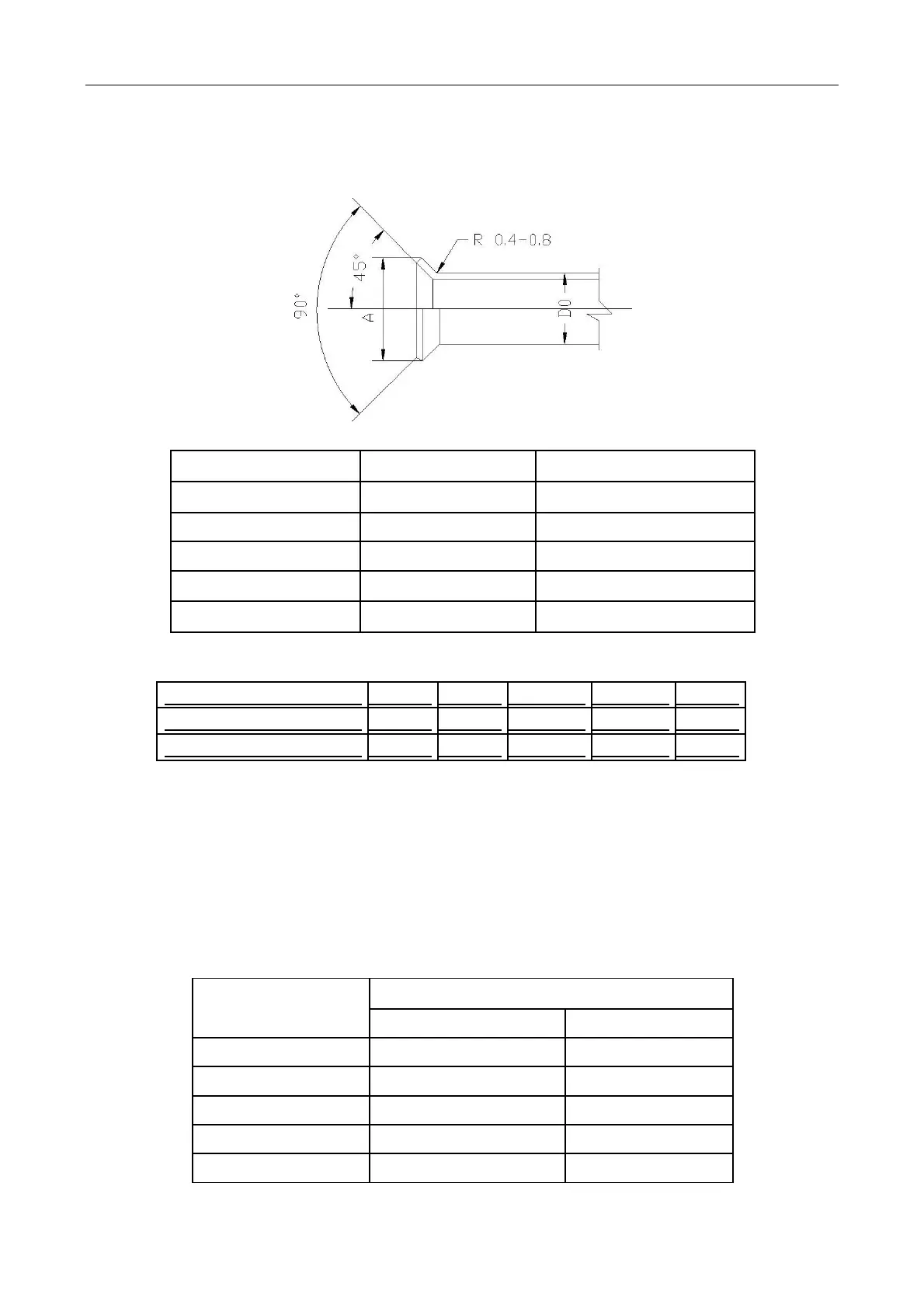

3) The flaring tool shall be used and the size of flare opening shall remain as follows:

Do not forget to consider the pipe nut in the situation specified for processing of flare opening.

Shape and Size of Flare Opening:

Dimension table (unit: mm)

Attention shall be paid to that the bore diameter of pipe nut shall be increased by 1mm based on the

dimension A; otherwise there is a possibility that the pipe nut cannot be assembled.

Notes: A. The flared side of R410A is deeper than that of R22;

B. The eccentricity between horn center and pipe center is set for 0.1mm or above;

C. There shall be no scar, crack and asperity at the horn position.

4) Apply the air‐conditioning oil on the inner and outer surface of the flare (for facilitating the smooth pass

of flare nut to prevent the distortion of the pipeline)

A. Carefully remove the burrs;

B. Use two wrenches to grab the pipe;

C. The flare nut shall be mounted onto the pipe before the pipe expansion operation;

D. The torque force shall be appropriate when using it to tighten the nut (standard torque ±10%)

72/ 113

Loading...

Loading...