2. MOTORS

- 26 -

(4) Maintenance of bearings

The service life of bearings varies with the magnitude of loads and operating conditions. Replace the

bearings with new ones when the temperature rises excessively or produces noise.

Sealed bearings sealing in lithium soap-based grease ensure effective lubrication and prevent the

entrance of dust. They can be used for a long period of time without adding grease.

The sealed bearing should be replaced using the following table as a rough guide.

Operation time 8 – 12 hours/day 12 hours/day

Replacement intervals Once every 6 years Once every 3 years

Earlier replacement may be required if the motor is used at a place which is dusty or might cause the

sealed grease to deteriorate or ow out due to the atmosphere of harmful gases or solvent.

■

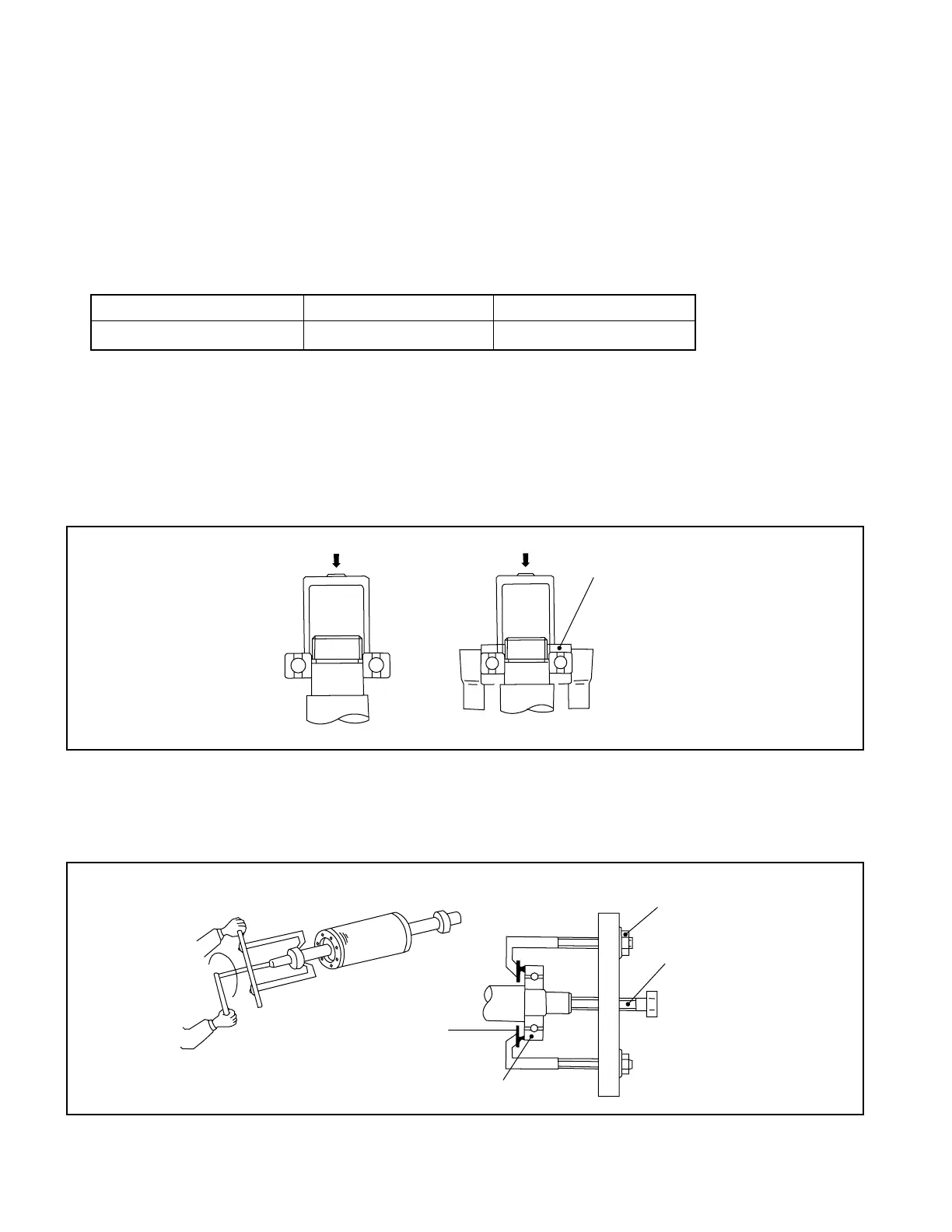

Installing bearing

Install the bearing onto the shaft using a pipe (with a patch, if needed), as shown in Fig. 2.8.

When heating the bearing, do not heat to more than 60 to 80°C [140 to 176°F].

PATCH

Fig. 2.8

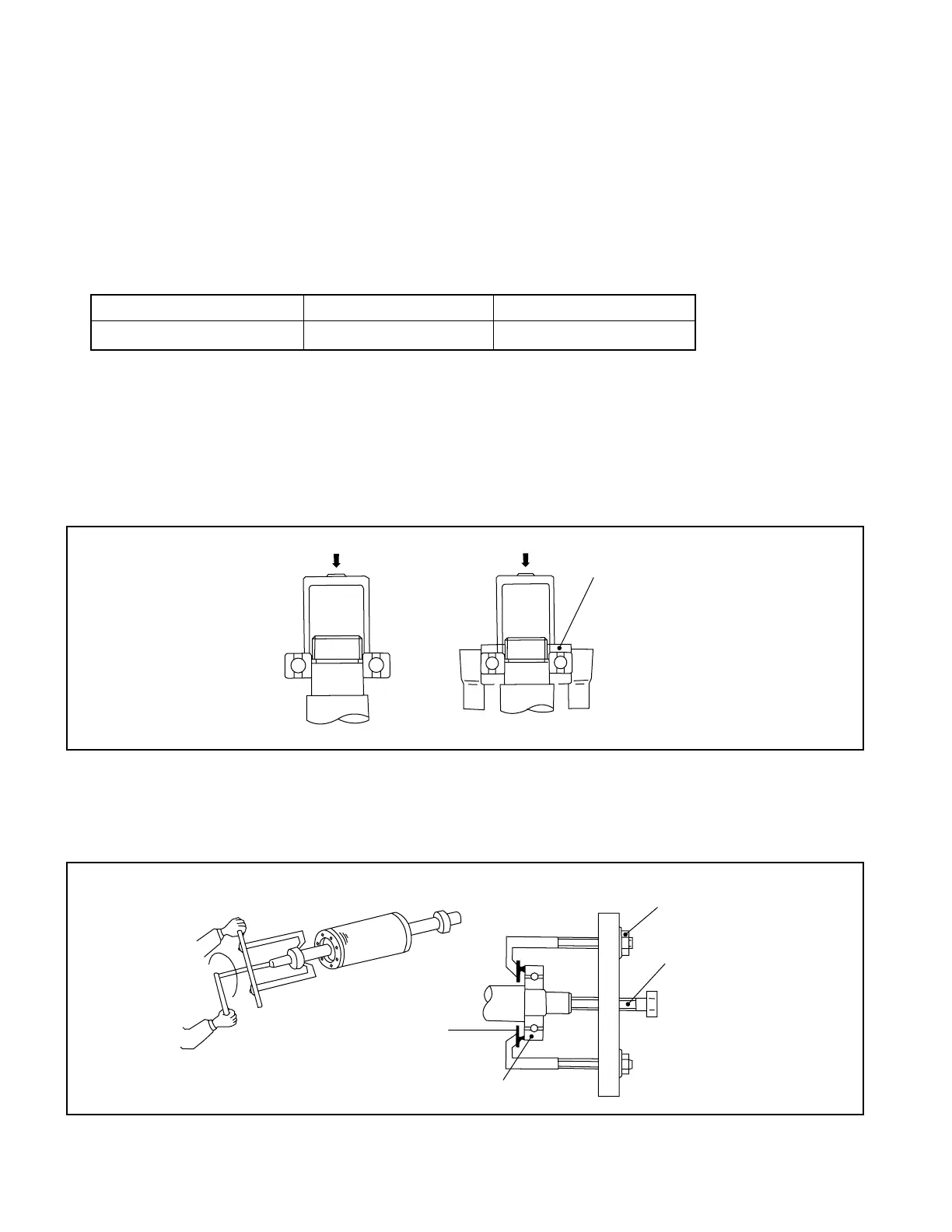

Fig. 2.9

INTERNAL

BEARING COVER

NUT

PULLER BOLT

BEARING

■

Removing bearing

Using a puller, remove the bearing.

Loading...

Loading...