© Technosoft 2007 35 IBL2403 Technical Reference

In order to avoid this situation add a capacitor on the motor supply big enough to absorb the

overall energy flowing back to the supply. The capacitor must be rated to a voltage equal or

bigger than the maximum expected over-voltage and can be sized with the formula:

Drive

NOM

MAX

M

C

UU

E

C −

−

×

≥

22

2

where:

U

MAX

- is the over-voltage protection limit expressed in [V]. You can read this value in the

“Drive Info” dialogue, which can be opened from the “Drive Setup”.

C

Drive

- is the drive internal capacitance ( 220 μF)

U

NOM

- is nominal motor supply voltage expressed in [V]. You can read this value in the

“Drive Info” dialogue, which can be opened from the “Drive Setup”.

E

M

- the overall energy flowing back to the supply in Joules. In case of a rotary motor

and load,

E

M

can be computed with the formula:

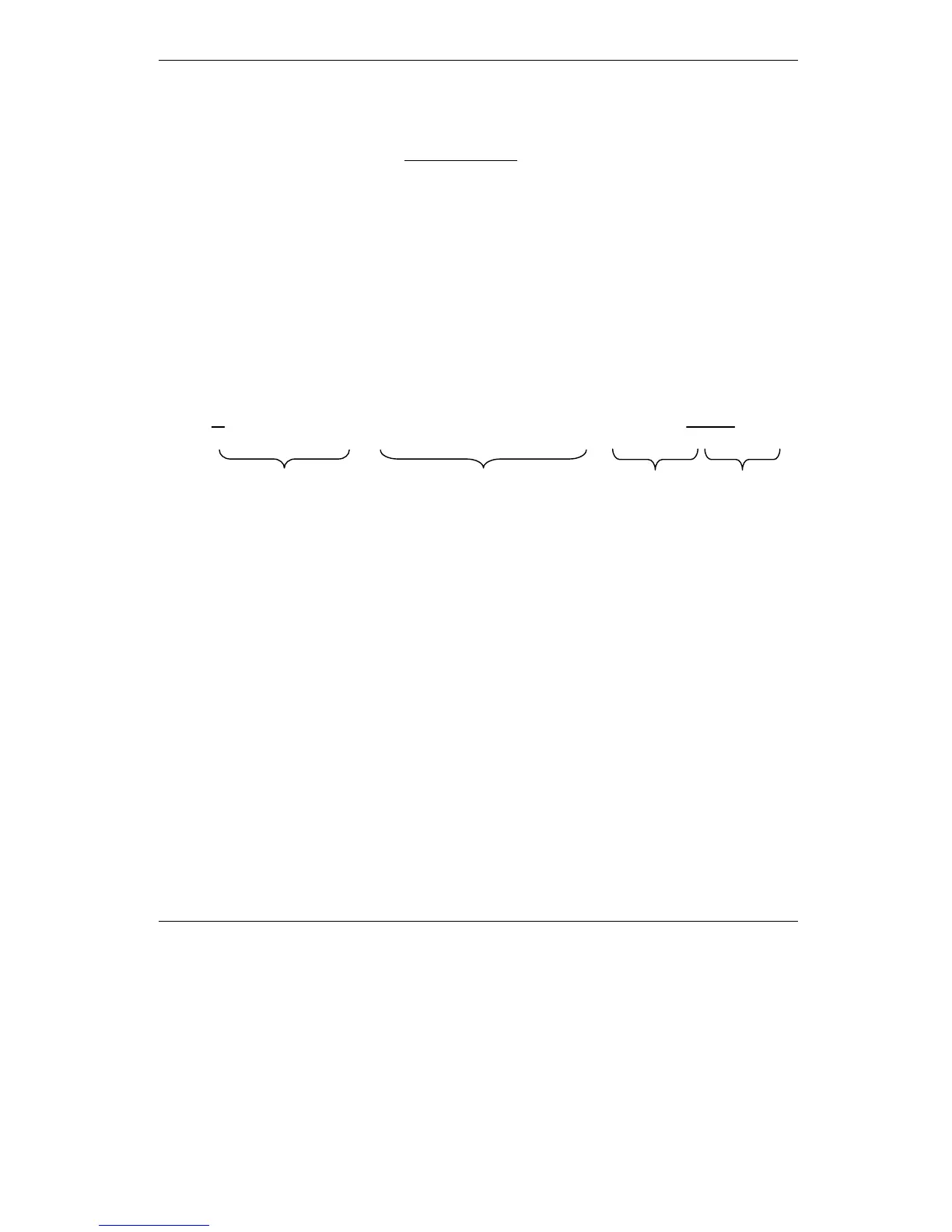

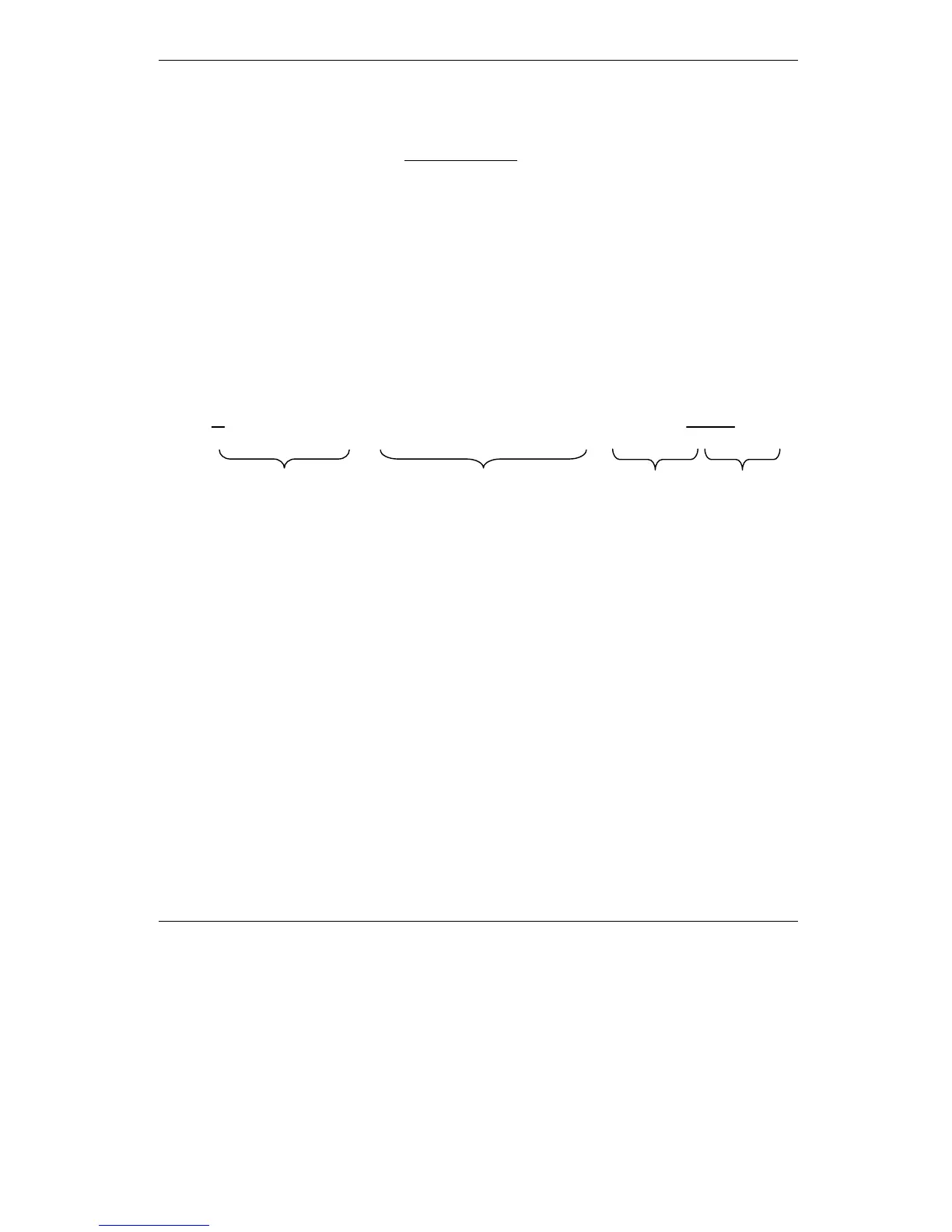

F

Md

dPh

2

M

finalinitialLMMLMM

T

2

t

tR3I)h-g(h)mm()J(J

2

1

E

ϖ

−−++ϖ+=

where:

J

M

– total rotor inertia [kgm

2

]

J

L

– total load inertia as seen at motor shaft after transmission [kgm

2

]

ϖ

M

– motor angular speed before deceleration [rad/s]

m

M

– motor mass [kg] – when motor is moving in a non-horizontal plane

m

L

– load mass [kg] – when load is moving in a non-horizontal plane

g

– gravitational acceleration i.e. 9.8 [m/s

2

]

h

initial

– initial system altitude [m]

h

final

– final system altitude [m]

I

M

– motor current during deceleration [A

RMS

/phase]

R

Ph

– motor phase resistance [Ω]

t

d

– time to decelerate [s]

T

F

– total friction torque as seen at motor shaft [Nm] – includes load and transmission

In case of a linear motor and load, the motor inertia J

M

and the load inertia J

L

will be replaced by

the motor mass and the load mass measured in [kg], the angular speed ϖ

M

will become linear

speed measured in [m/s] and the friction torque T

F

will become friction force measured in [N].

Kinetic energy Copper losses Friction losses Potential energy

Loading...

Loading...