115-0917-010 14

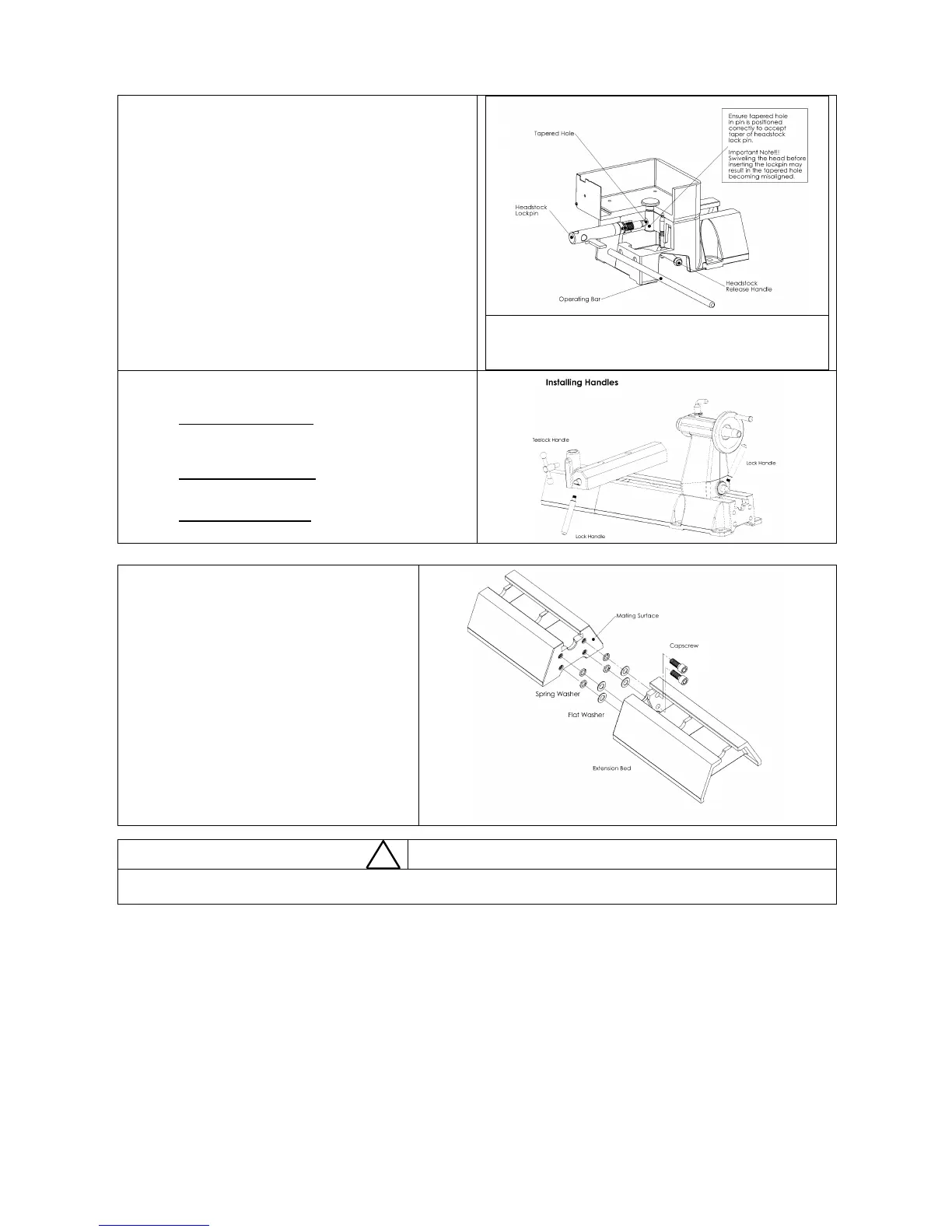

Installing the Headstock Lock Pin and Handles

5. Remove the plastic shipping tube from headstock base.

Immediately screw the Headstock Lock Pin into the

threaded hole at the bottom of the headstock. Insert the

operating bar into the hole in the Lock Pin and firmly tighten

the Lock Pin to lock the headstock in position; then remove

the operating bar.

Note: When the pin is fully engaged, the groove machined into

the pin furthest from the thread should line up with the edge

of the hole in the casting. By doing this the pin will be

engaged in the hole of the swivel pin.

6. Loosen the Lock Pin 1 – 2 turns. Push the Headstock

Release Handle down and rotate the Headstock so the

spindle points to the tailstock and lines up parallel to the

lathe bed. Tighten lock pin again.

Note: Do not use excessive force when tightening the Lock Pin.

Important note:

Swiveling the headstock before inserting the lock pin may

result in the tapped hole on the Swivel pin becoming

misaligned.

7. Assemble the handles:

Note: Some handles may come pre-assembled.

Tool Rest Clamp Handle -

Insert the rod through the handle and screw the ball

knobs onto each end of the rod.

Tool Slide Clamp Handle –

screw the lock handle into the tool slide.

Tailstock Clamp Handle –

screw the lock handle into the tailstock.

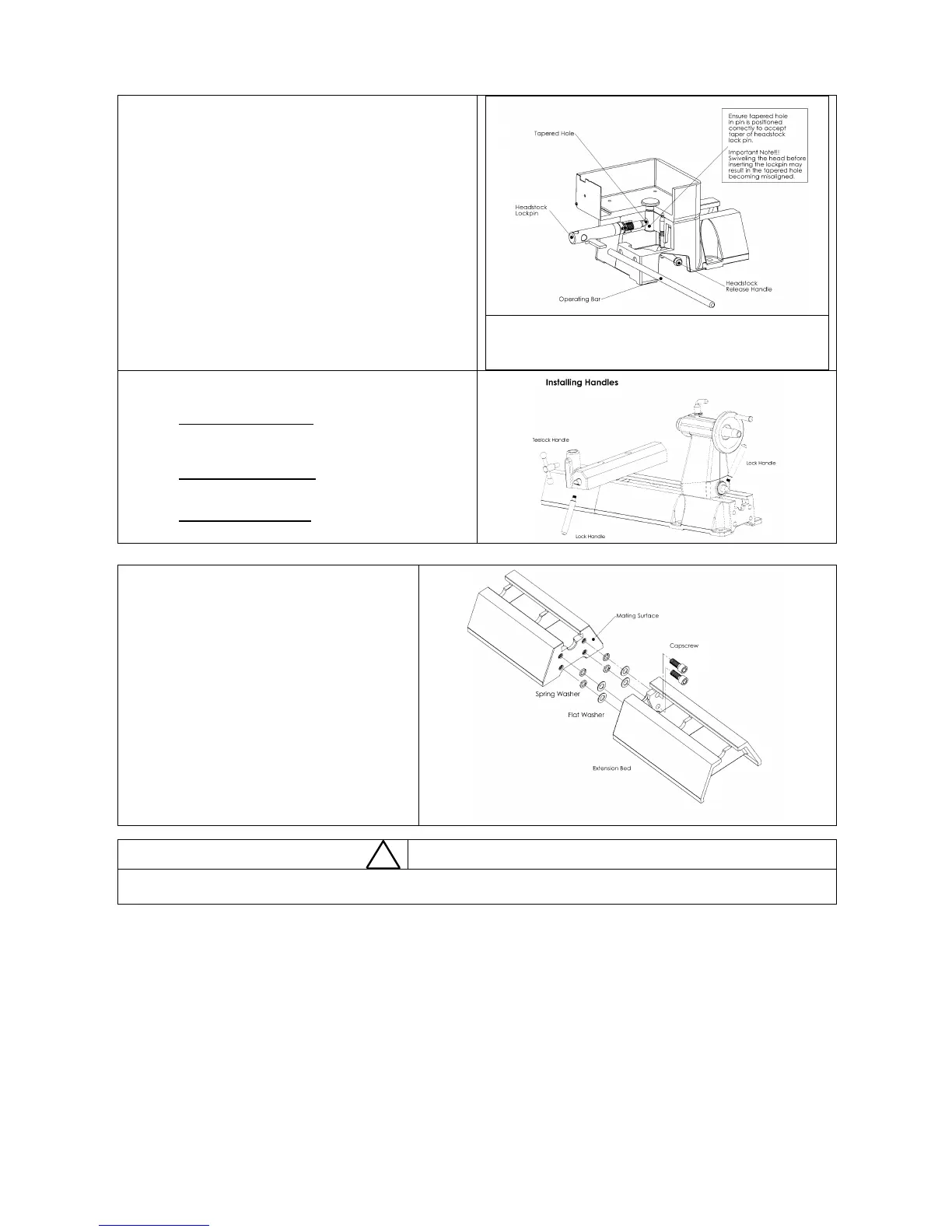

Each cast iron extension bed adds 510mm (20in.) to

the lathe’s capacity to turn between centers.

1. Clean the joining ends of both bed sections with a

petroleum-based solvent. Make sure there are no

dents or burrs on either mating surface. Remove

burrs and high spots with a smooth file.

2. Screw in cap screws tight.

3. Secure the bed sections together with four

M12x30 cap screws using a 10mm Allen wrench.

It may be necessary to move the lathe so the cap

screws can be reached with the wrench from the

bottom of the bed.

Do not use a metal hammer to pound on the extension bed. This may damage the bed, affect accuracy and

tailstock action, and may prevent you from adding another extension bed.

4. Bring the Tailstock along until it is on top of the join area where the bed extension face meets the lathe bed face. The bed extension

may require manipulations up-and-down and sideways in order for the Tailstock to fit.

5. Check that the tool slide and tailstock move freely over the mating joint and also over the full length of the add-on extension. If there

is a ridge between the two mating surfaces then repeat steps 1 - 4 again, use a smooth file to file the surfaces flush.

6. Follow the suggestions under "Mounting the Lathe to a Support Surface".

Loading...

Loading...