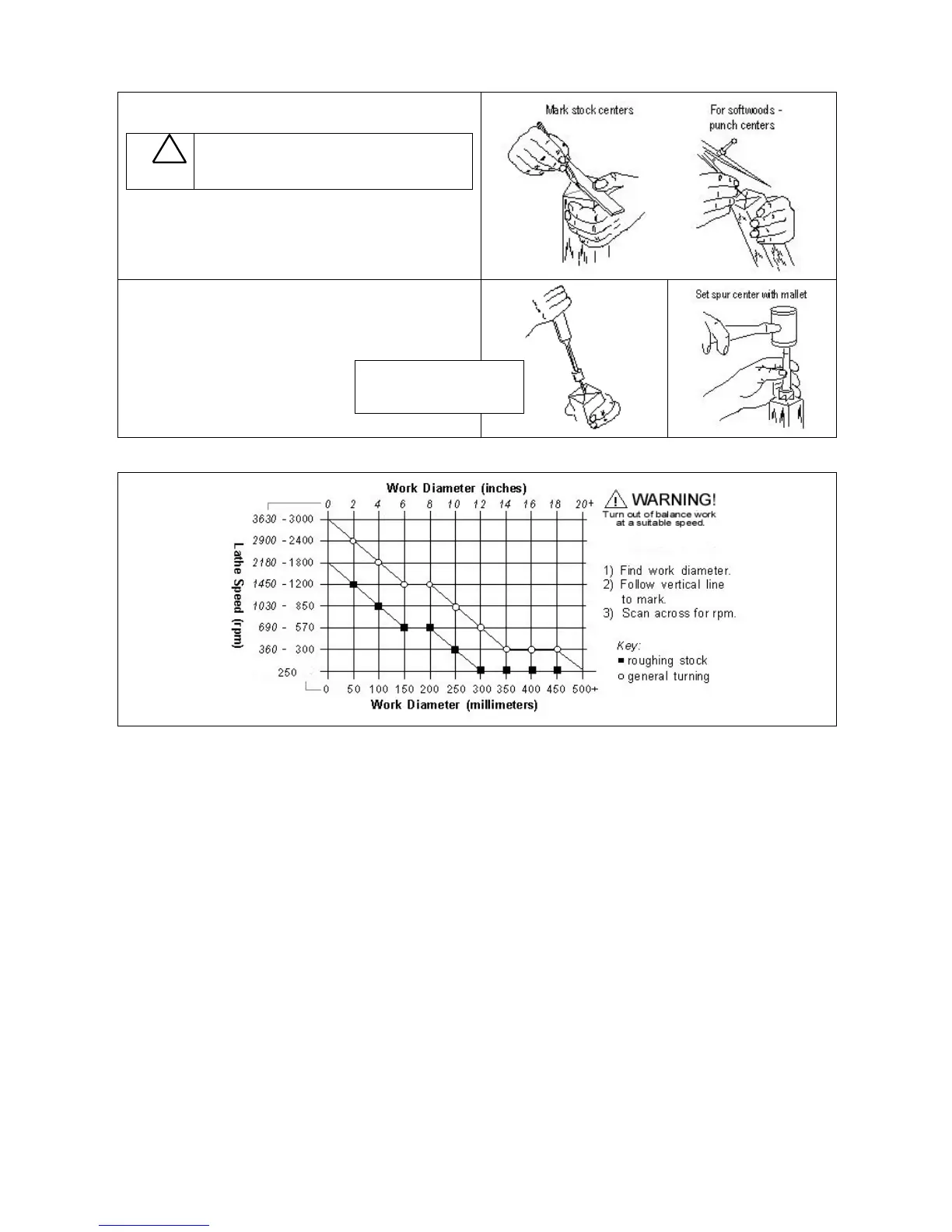

Mount the spur center to the work piece as shown and then insert

the spur center and work piece into the headstock spindle.

To remove the center, insert a 10mm (3/8-inch) diameter wooden

dowel or steel rod through the headstock spindle hole. While

holding the center so it doesn’t fall, tap it out.

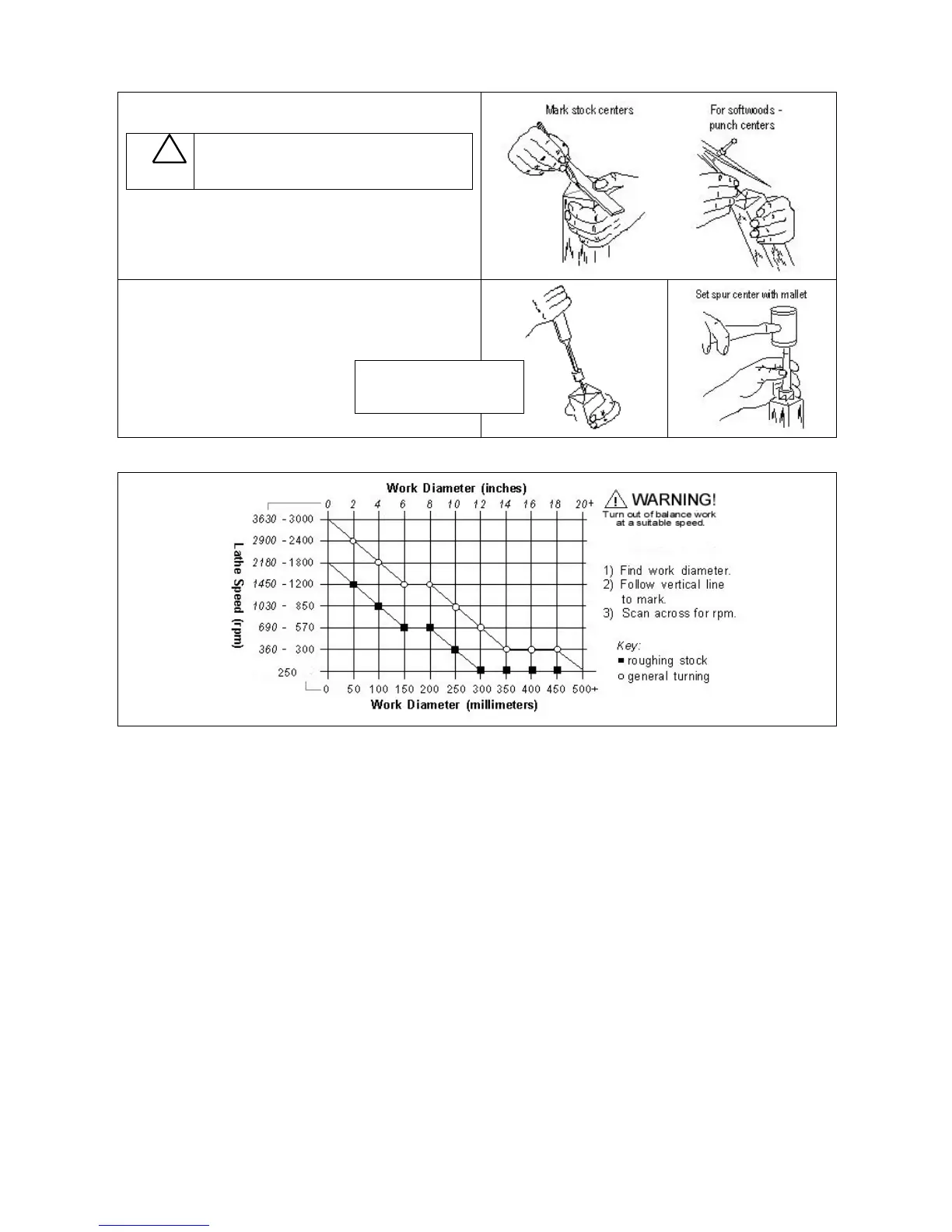

Correct selection of turning speeds is important for safety and finish cut quality

It is important to take the fixing of the work piece into account, it should be made as secure as possible. Various techniques are available

for this consult books on the subject and seek training opportunities.

There are safety and out of balance considerations. Aim for a good balance in turning speed, ensure good fixing and try to balance timber

as much as possible before installing on lathe.

In general wood likes being sliced and if too low a speed is used the timber can "hammer" against the cutting tool, tearing fibers and

imposing large forces on the tool and work piece. This can often be dangerous, it is best to select a higher speed as the cuts will be

smoother and less force is imposed on the work piece. It can be likened to a wood plane, if it is pushed very slowly, more force is needed

to break the fibers. If the plane is pushed at a higher speed less forces are involved and a better cut results. Use 250 rpm when needed,

but it is better turning at 400-600 rpm.

Loading...

Loading...