29 115-0917-010

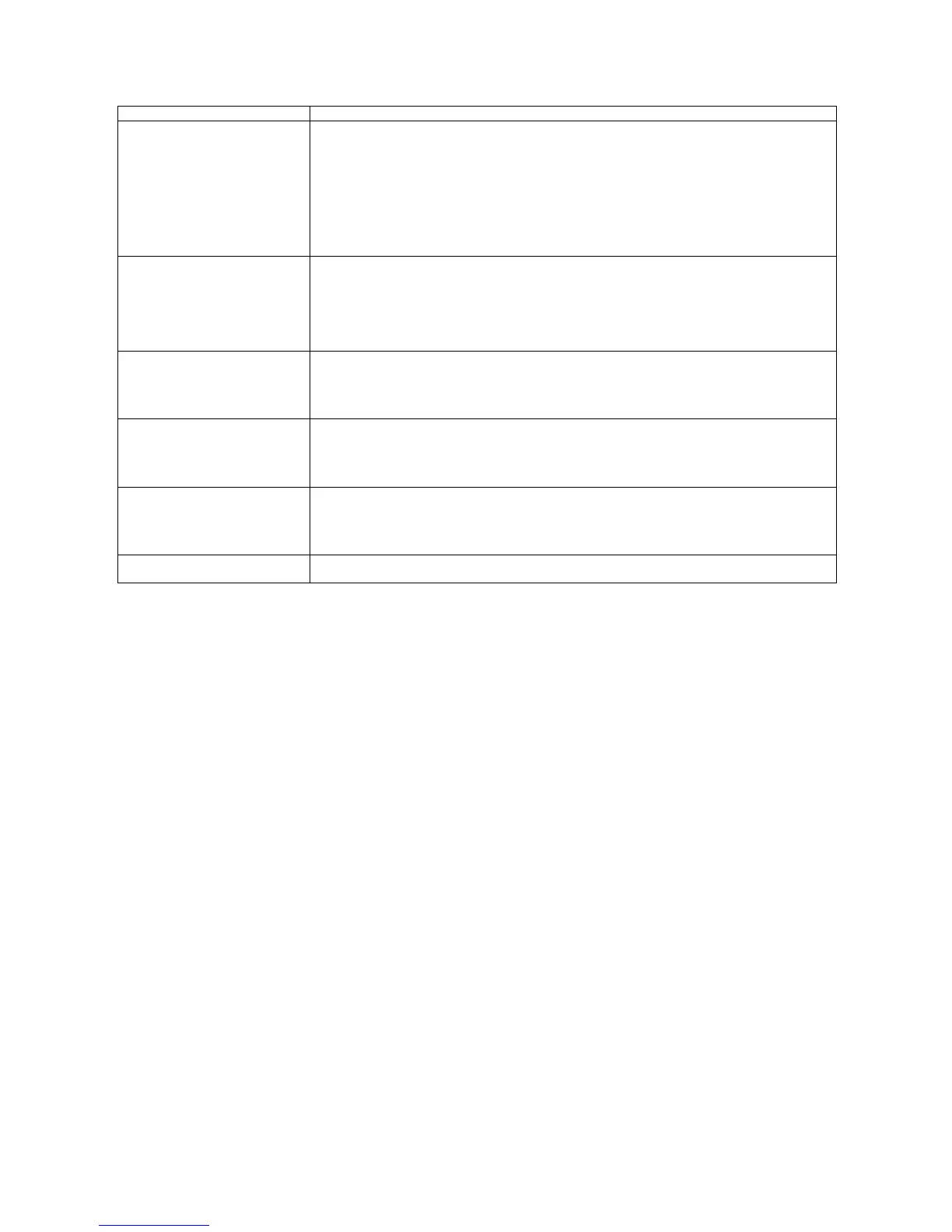

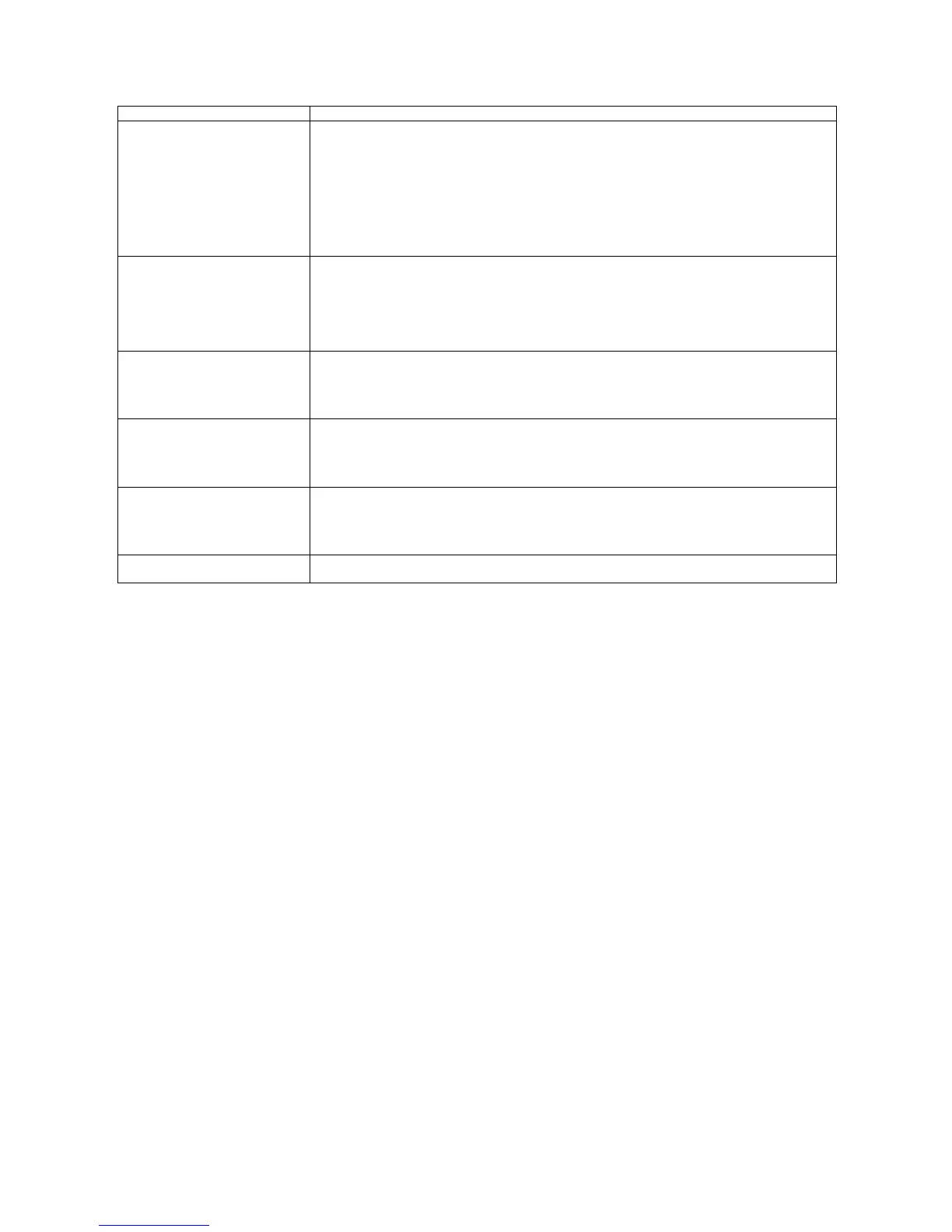

Troubleshooting Guide (Continued)

Possible Cause and Solution

Tailstock and headstock center

not lining up correctly

Bed incorrectly bolted to stand causing twist. Ensure stand and lathe are correctly installed.

Headstock not returned to detent position after it has been rotated. Ensure that the headstock is

locked into a detent position.

Headstock Lock pin not fully seated. Twist the headstock back and forth to make sure it is properly

seated and then tighten the Lock pin.

Dirt or wood dust accumulated in the headstock swivel pin hole. Remove the Headstock Lock pin

and clean out hole.

Tailstock Handwheel hard to turn

or will not turn

Quill lock is locked; unlock the quill lock. If necessary, lightly tap a block of wood against

handwheel handle and tap the handle in a clockwise direction as viewed from the tailstock end.

Build-up of dust and wood resin on the quill or inside of the handwheel thread. Remove, clean, and

lubricate the quill and tailstock as described under "Cleaning the Tailstock".

The quill has been extended too far and is locked against the handwheel. Push the quill back into

the tailstock when turning the handwheel.

Tailstock quill hard to move

Quill lock is locked; unlock the quill lock.

The quill is damaged; turn the handle to expose the quill and check for marks along the quill,

especially on the edges of the slotted keyway. Remove the high spots with a smooth file and test

the quill travel. Replace the quill if necessary.

Tailstock not locking correctly

onto bed, or tailstock not sliding

smoothly on bed ways

Tailstock adjustment plate not adjusted correctly; adjust as described under "Aligning the

Tailstock".

Dirty bed ways and underside of tailstock body. Clean bed ways and underside of tailstock body

with a petroleum-based solvent.

The inside of the bed has a high spot. File the area with a smooth flat file until the tailstock moves

freely.

The tailstock adjustment plate has a rough spot or a burr. Remove the tailstock and file the plate

with a smooth flat file.

Tailstock jumps where bed

sections join

The machined flat surfaces are not flush. File the area with a smooth flat file until the tailstock

moves freely

Note: Can't find the answer in this Trouble Shooting guide?

Visit the Lathe Support Section on our website - this is packed with Frequently Asked Questions.

Or

Contact Us (details are at the front of this manual)

Loading...

Loading...