Maintenance—2215A Service

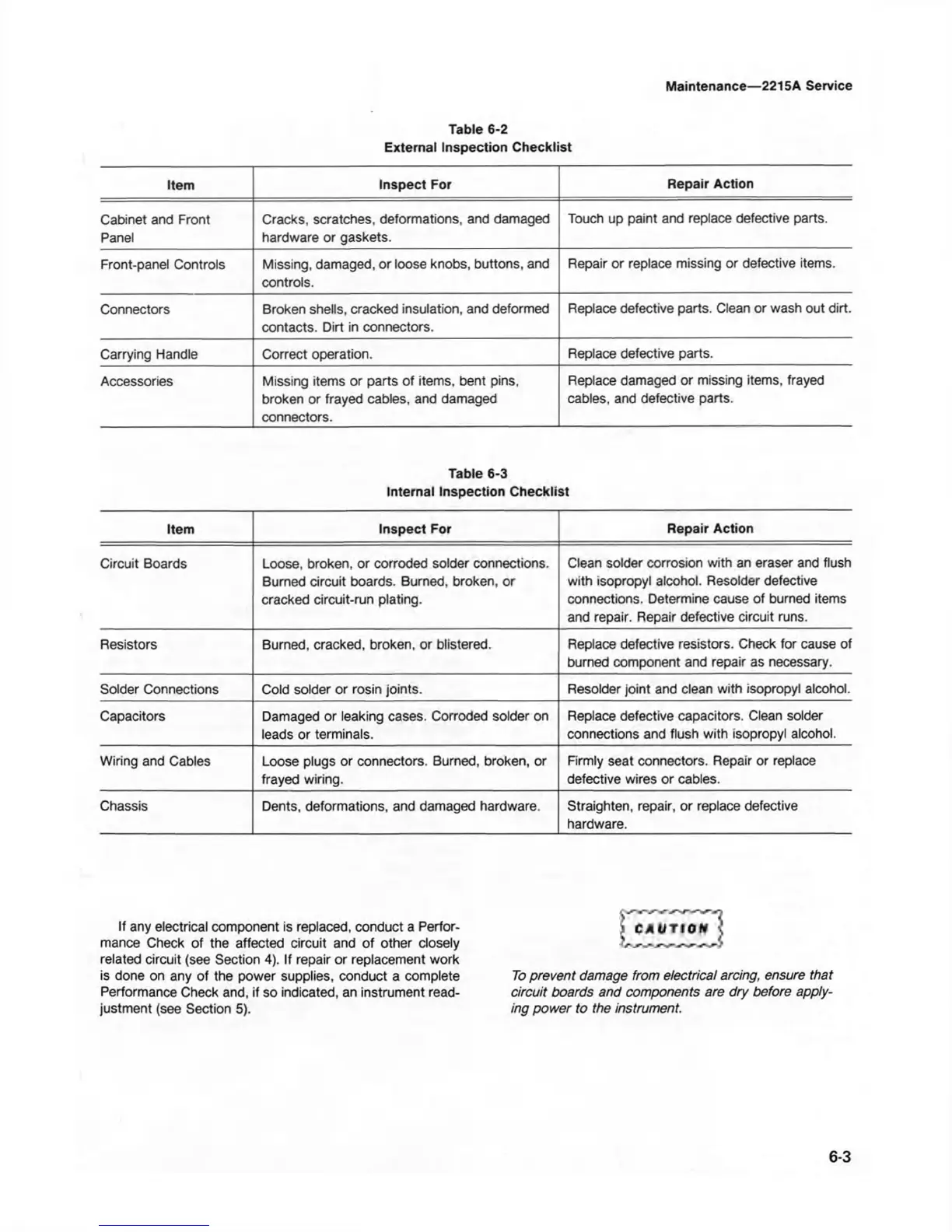

Table 6-2

External Inspection Checklist

Item

Inspect For

Repair Action

Cabinet and Front

Panel

Cracks, scratches, deformations, and damaged

hardware or gaskets.

Touch up paint and replace defective parts.

Front-panel Controls

Missing, damaged, or loose knobs, buttons, and

controls.

Repair or replace missing or defective items.

Connectors

Broken shells, cracked insulation, and deformed

contacts. Dirt in connectors.

Replace defective parts. Clean or wash out dirt.

Carrying Handle

Correct operation.

Replace defective parts.

Accessories

Missing items or parts of items, bent pins,

broken or frayed cables, and damaged

connectors.

Replace damaged or missing items, frayed

cables, and defective parts.

Table 6-3

Internal Inspection Checklist

Item Inspect For

Repair Action

Circuit Boards Loose, broken, or corroded solder connections.

Burned circuit boards. Burned, broken, or

cracked circuit-run plating.

Clean solder corrosion with an eraser and flush

with isopropyl alcohol. Resolder defective

connections. Determine cause of burned items

and repair. Repair defective circuit runs.

Resistors Burned, cracked, broken, or blistered.

Replace defective resistors. Check for cause of

burned component and repair as necessary.

Solder Connections Cold solder or rosin joints.

Resolder joint and clean with isopropyl alcohol.

Capacitors Damaged or leaking cases. Corroded solder on

leads or terminals.

Replace defective capacitors. Clean solder

connections and flush with isopropyl alcohol.

Wiring and Cables Loose plugs or connectors. Burned, broken, or

frayed wiring.

Firmly seat connectors. Repair or replace

defective wires or cables.

Chassis Dents, deformations, and damaged hardware.

Straighten, repair, or replace defective

hardware.

If any electrical component is replaced, conduct a Perfor

mance Check of the affected circuit and of other closely

related circuit (see Section 4). If repair or replacement work

is done on any of the power supplies, conduct a complete

Performance Check and, if so indicated, an instrument read

justment (see Section 5).

To prevent damage from electrical arcing, ensure that

circuit boards and components are dry before apply

ing pow er to the instrument.

6-3

Loading...

Loading...