NVRAMFailure

Anything that causes bad data to be stored in the

NVRAM (nonvolatile RAM) will cause a failure of one or all

of the 6000 level tests (CKSUM-NVRAM). Loss of stored

data from the NVRAM can cause seemingly unrelated

failures in the diagnostic tests. That is because all the fail

flags and calibration constants against which the current

testing is performed are stored in the NVRAM. Checking

against erroneous data and marking failures using bad

flags provides failure indications not related to a hardware

failure. Doing a "COLD START" (see "Special Diagnostic

Features") loads all the NVRAM locations with known

nominal values and removes the invalid data. This permits

SELF CAL and testing to be completed correctly. Replac-

ing the NV RAM or the Lithium storage battery requires a

COLD START to restore the NV RAM data to known

values. Even though the SPECIAL menu choices may be

disabled from front-panel access, a COLD START is done

automatically when the instrument finds no stored calibra-

tion constants during the first power-on after the

replacement.

Power-On/Self Diagnostics Test Failure

If the Self Diagnostics tests fail, either at power-on or

when called by the user from the front panel, the

"EXTENDED DIAGNOSTICS" mode will be entered. The

menu displayed in Extended Diagnostics permits the user

to determine which test(s) failed as a start in isolating the

fault to the problem area (see Table 6-6). A failure of tests

6000-9300 does not necessarily indicate a fatal instrument

fault. An abnormal power-off or transient power condition

may have prevented the orderly shutdown that normally

saves the data needed to return the scope to the operat-

ing state present at power-off. A failure of the SELF DIAG-

NOSTICS will also occur if the present temperature of the

scope is very different from the temperature during the last

SELF CAL. In the last case, the stored calibration con-

stants may not permit accurate measurements to be

made.

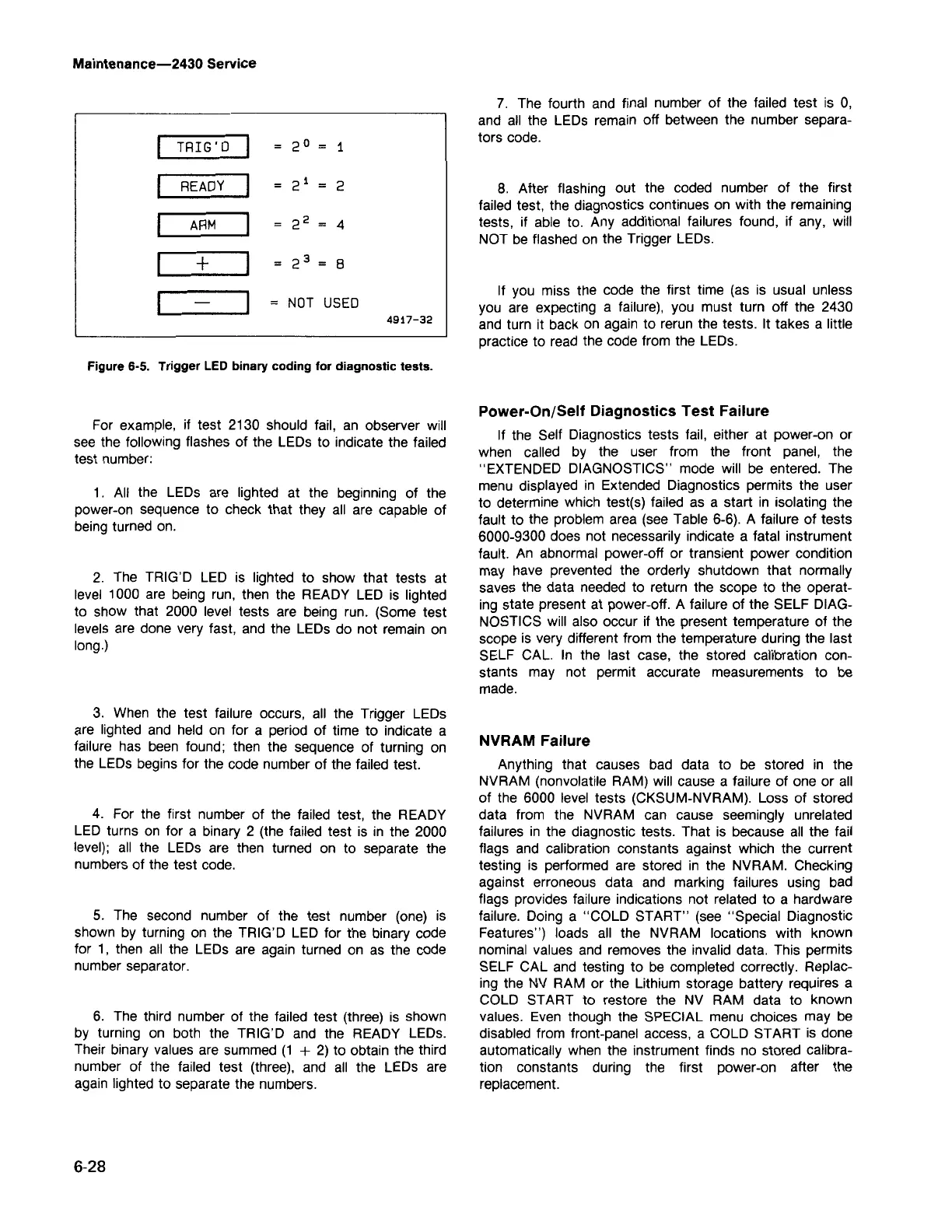

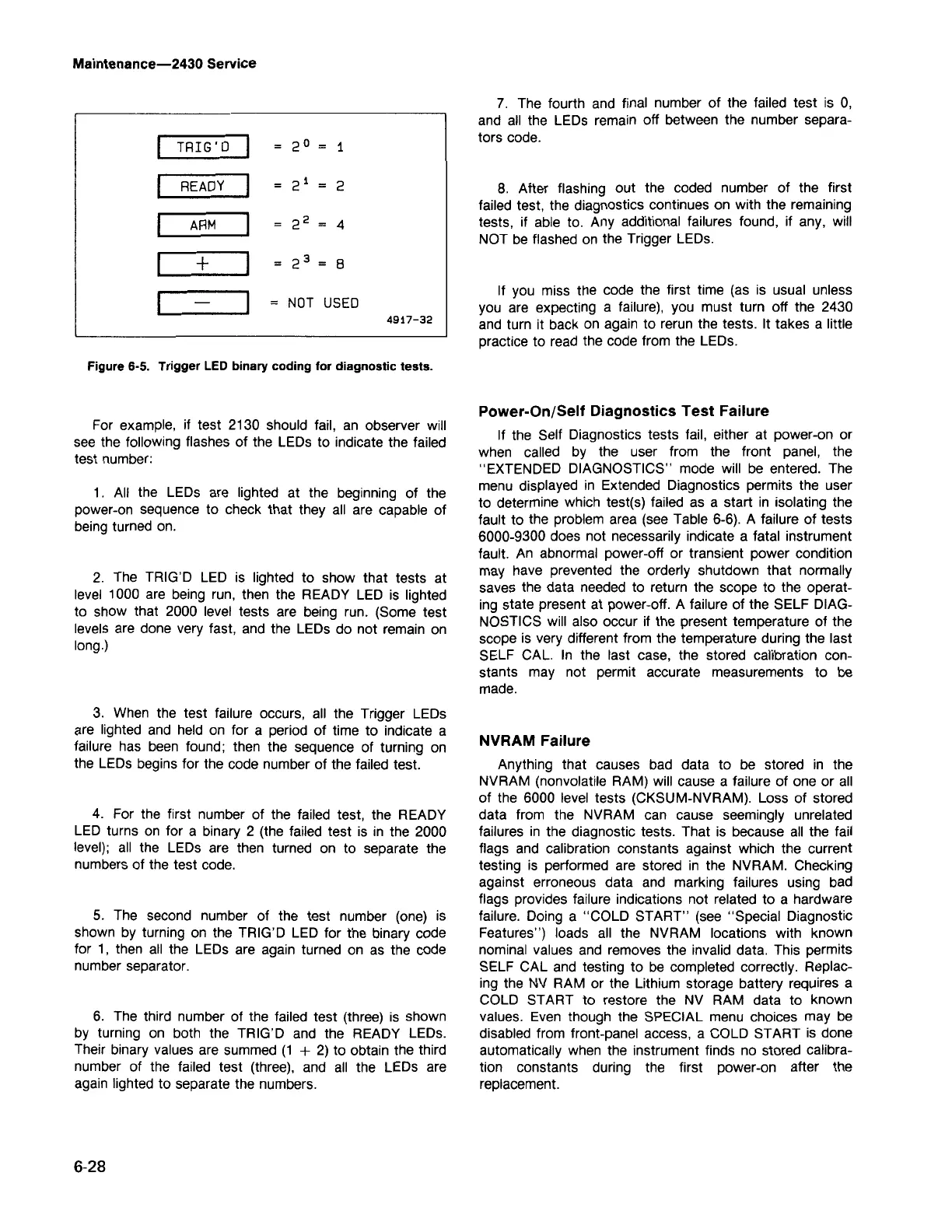

If you miss the code the first time (as is usual unless

you are expecting a failure), you must turn off the 2430

and turn it back on again to rerun the tests. It takes a little

practice to read the code from the LEOs.

8. After flashing out the coded number of the first

failed test, the diagnostics continues on with the remaining

tests, if able to. Any additional failures found, if any, will

NOT be flashed on the Trigger LEOs.

7. The fourth and final number of the failed test is 0,

and all the LEOs remain off between the number separa-

tors code.

6-28

6. The third number of the failed test (three) is shown

by turning on both the TRIG'D and the READY LEOs.

Their binary values are summed (1 + 2) to obtain the third

number of the failed test (three), and all the LEOs are

again lighted to separate the numbers.

5. The second number of the test number (one) is

shown by turning on the TRIG'D LED for the binary code

for 1, then all the LEOs are again turned on as the code

number separator.

4. For the first number of the failed test, the READY

LED turns on for a binary 2 (the failed test is in the 2000

level); all the LEOs are then turned on to separate the

numbers of the test code.

3. When the test failure occurs, all the Trigger LEOs

are lighted and held on for a period of time to indicate a

failure has been found; then the sequence of turning on

the LEOs begins for the code number of the failed test.

2. The TRIG'D LED is lighted to show that tests at

level 1000 are being run, then the READY LED is lighted

to show that 2000 level tests are being run. (Some test

levels are done very fast, and the LEOs do not remain on

long.)

1. All the LEOs are lighted at the beginning of the

power-on sequence to check that they all are capable of

being turned on.

For example, if test 2130 should fail, an observer will

see the following flashes of the LEOs to indicate the failed

test number:

Figure 6-5. Trigger LEDbinary coding for diagnostic tests.

TRIG'D

2°

1

READY

21

2

ARM

22

4

+

23

=

8

=

NOT USED

4917-32

Maintenance-2430 Service

Loading...

Loading...