EX-TRAFIRE

®

45SD

Operator Manual, Revision T-52-14

Specifications: Torches FHT-EX

®

45TTH and FHT-EX

®

45TTM

Torch Torch FHT-EX

®

45TTH/M

Recommended capacity 12 mm*

Maximum capacity

25 mm*

Piercing capacity

10 mm*

Plasma cutting - 10 °C to + 40 °C

Transport and storage - 25 °C to + 55 °C

Relative humidity up to 90 % at 20 °C

Application process Plasma Cutting, Gouging

Type of use manual and mechanized

Pilot current 20 A at 45 A setting

Rated current and corresponding duty cycle 45 / 100%

Type of gas compressed air / Nitrogen

Gas flow rate approx� 90 l/min

Max� inlet pressure 10 bar

Operating (dynamic) pressure 4�8 bar

Gas post flow delay ≥ 20 sec�

Type of voltage DC direct voltage

Protection type of the machine-side connections IP3X (EN 60 529)

Type of connection TCS (torch connection system) - 13 pin

Voltage rating 500V peak value

Rated value of control leads (trigger and cap sensor) 42 VAC / 0�1-1A

Standard lenght (other length availible on request) 5 m / 8 m / 15 m

Structure of cable coaxial cable

*Cutting capacity (Values for low alloyed steel, e�g� Mild Steel S235JR)

The FHT-EX

®

cutting torches are designed for plasma cutting of metalic conductive materials�

Torch construction: torch body, handle or mounting tube, leadset and consumables�

FHT-EX

®

torches fulfill the requirements of IEC/EN 60974-7�

Weight

FHT-EX

®

45TTH Hand Torch

5 m / 1�5 kg

8 m / 2�2 kg

15 m / 3�6 kg

FHT-EX

®

45TTM Machine Torch

5 m / 1�5 kg

8 m / 2�2 kg

15 m / 3�6 kg

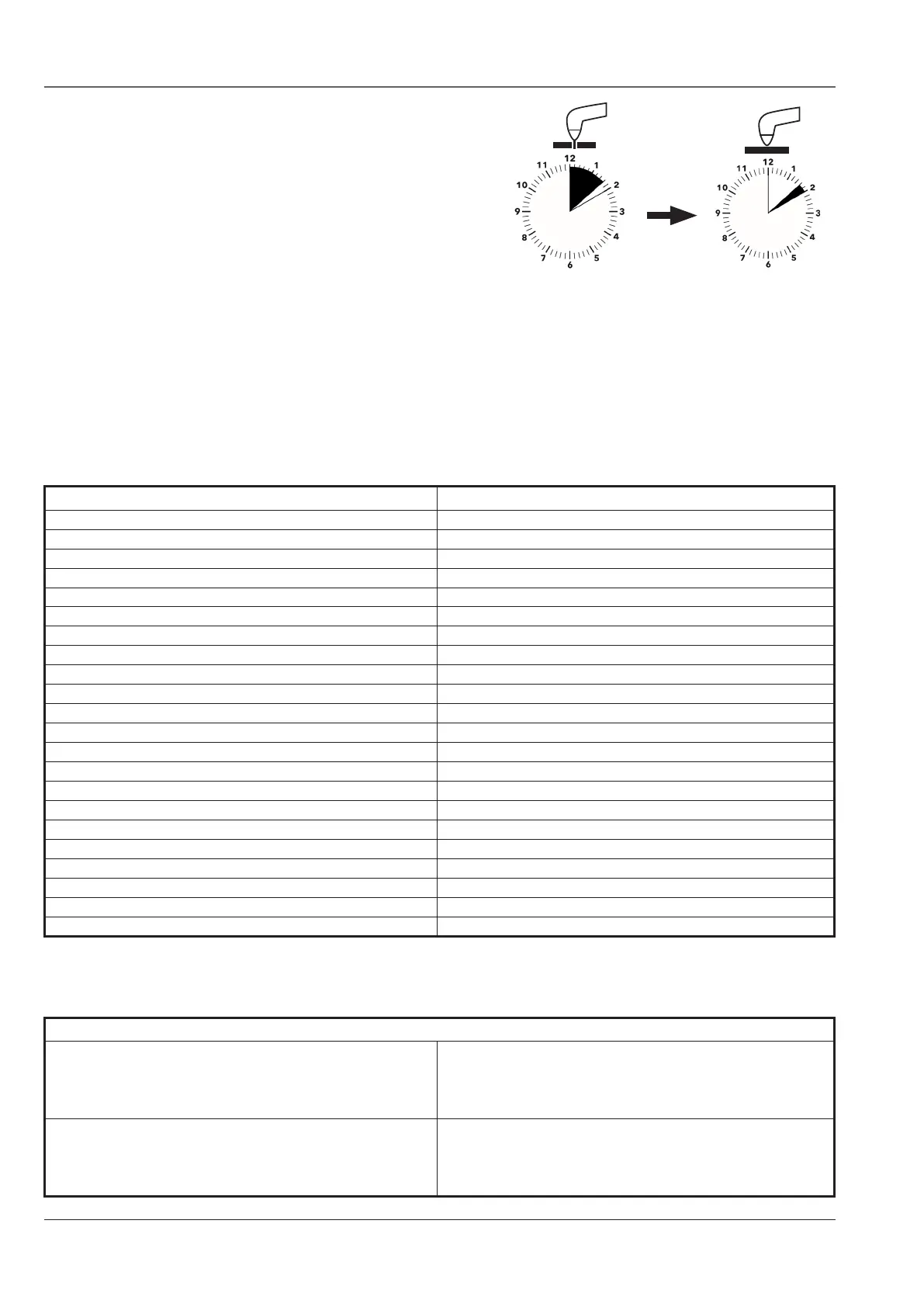

8 minutes cutting 2 minutes resting

Duty cycle

Duty cycle is the percentage of time,

during a period of 10 minutes,

that the power supply can continuously cut�

The following diagram represents a duty cycle of 80%�

Loading...

Loading...