cutmaster 102

Manual 0-4998 5-17 SERVICE

B. SHORTED TORCH (OUTPUT) FAULT.

Fault indicator and 85 PSI Indicators are

flashing at 1 cycle per second.

This is a Latched Failure Mode. After START signal is

activated, gas flows for two (2) seconds then momen-

tarily shuts off then back on, FAULT INDICATOR

flashes, and 85 PSI LED flashes. To reset the machine,

turn the unit OFF, indentify and clear the problem

and turn back ON.

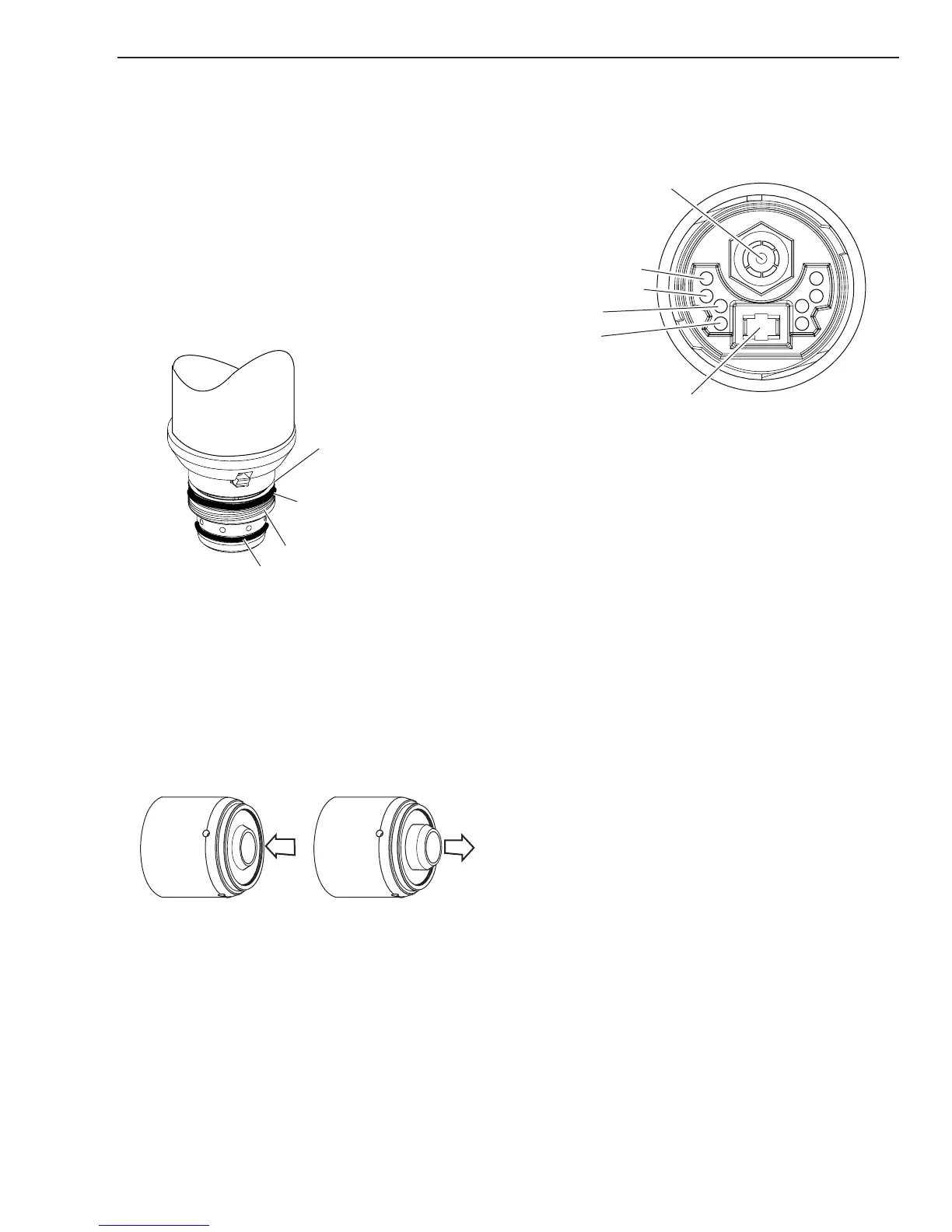

1. Upper O-Ring on torch head is in the wrong posi-

tion.

a) Remove shield cup from torch; check position

of the upper o-ring and correct if needed.

Upper Groove

with Vent Holes

Must Remain Open

Threads

Upper O-Ring

in Correct Groove

Lower O-Ring

Art # A-03725

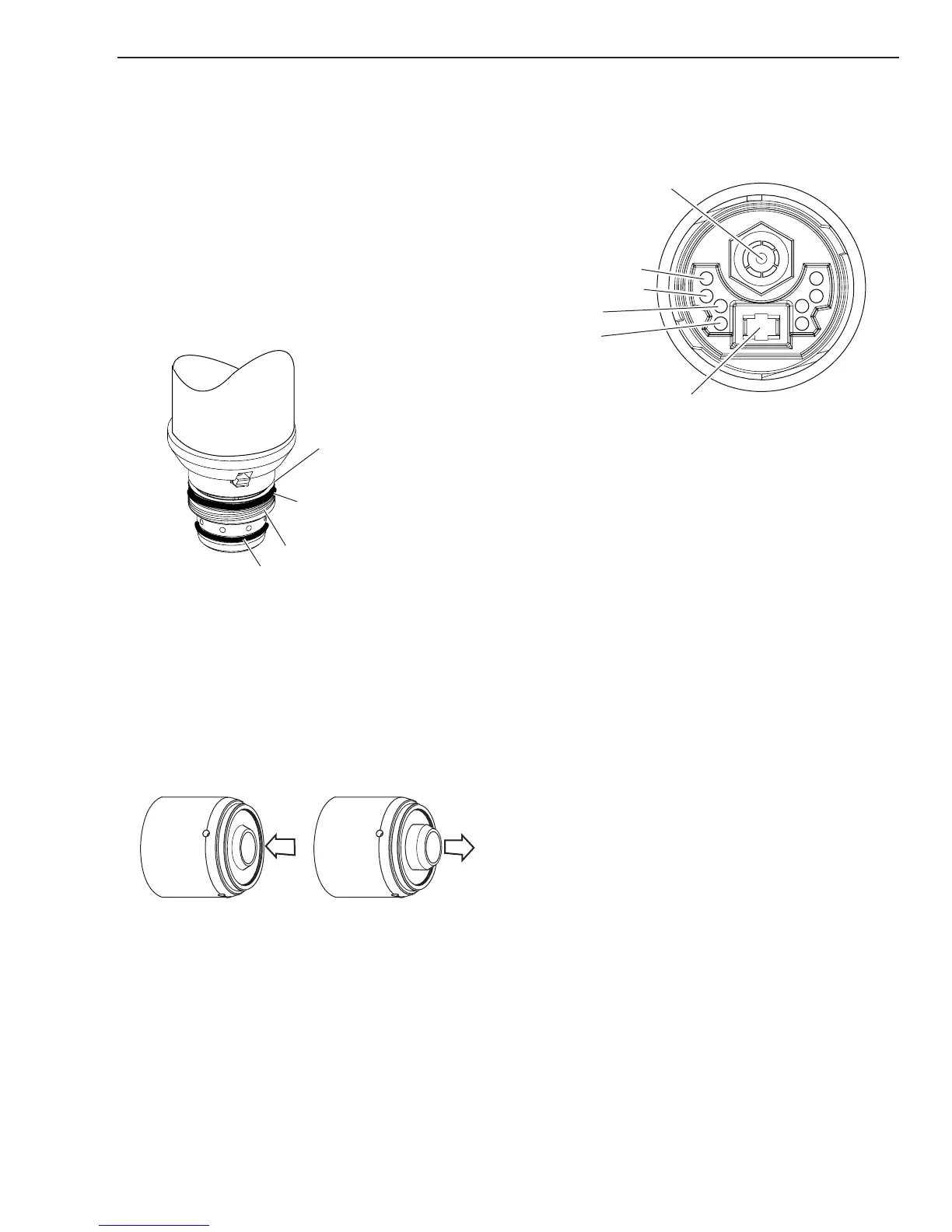

2. Torch start cartridge is stuck.

a) Turn off power supply. Bleed down the system.

Remove the shield cup, tip,start cartridge and

electrode. Check the lower end unit of the

start cartridge for free movement. Replace

the cartridge if the lower end unit does not

move freely.

Art # A-08064

Spring-Loaded

Lower End Fitting

Full Compression 1/8”

Spring-Loaded

Lower End Fitting at Rest /

Full Extension

3. Worn or faulty torch parts

a) Inspect torch consumables parts. Replace if

necessary.

4. Shorted Torch/leads

a) Disconnect torch from unit. With consumables

removed from the torch, Check continuity of

torch at ATC, between negative/plasma lead

connection to pilot lead connection.

Negative / Plasma Lead

4 Torch Switch

3 Torch Switch

2 PIP

1 PIP

Pilot Lead

Art # A-08124

If a short is found, the problem is in the torch

and leads assembly. Remove the torch head

from the leads and check the leads and head

to determine which is defective.

5. Defective 40Amp PCB 5.

a) Disconnect and isolate the wire from the

CHOKE1 connection on the 40Amp PCB 5.

Supply a START signal. If the FAULT is not

present, replace the 40 AMP PCB 5.

6. Defective Main PCB 1.

a) Replace Main PCB 1.

C. SHORTED TORCH FAULT. Fault indicator

and 85 PSI Indicators are flashing at 5

cycles per second.

This mode is a non-latched mode.

1. While using an Automation Torch at current set-

tings above 45 amps, the tip has contacted the

work piece.

a) Check standoff height

2. Air restriction in torch resulting in low voltage

during pilot.

a) Check torch consumables for wear or debris.

3. Low voltage during cutting due to torch or con-

sumable problem.

a) Check torch consumables for wear or debris.

In all three cases, to reset the machine, remove the

START signal.

Loading...

Loading...