cutmaster 102

SERVICE 5-20 Manual 0-4998

F. INTERNAL ERROR FAULT INDICATOR AND

90 PSI INDICATOR FLASHING

1. There has been a microprocessor problem.

a) Turn ON/OFF SWITCH to OFF position and

then turn to ON position to clear the error

2. Defective Logic PCB 3.

a) Replace Logic PCB 3.

5.10 CNC Interface Problems

A. Nothing happens when jumper is installed

between J2-3 to J2-4.

1. Defective Automation Interface PCB 4.

a) Measure voltage on PCB4 between J1-6 to J1-8

for 12VDC.

If 12VDC is present replace Automation Interface

PCB 4

2. Defective Main PCB 1.

a) Measure voltage on Main PCB 1 between J1-6

to J1-8 for less than 2VDC.

If voltage is less than 2VDC, replace Main PCB`1.

B. No OK-TO-MOVE signal while cutting.

1. Defective Main PCB`1

a) Measure voltage on PCB4 between J1-1 to J1-3

for 12VDC while cutting.

If 12VDC is present, replace PCB 1

2. Defective Automation Interface PCB 4

a) Measure voltage on PCB 4 between J1-1 to J1-3

for less than 2VDC while cutting.

If voltage is less than 2VDC, replace PCB 4.

C. ARC VOLTS signals are low or not present

1. Defective Automation Interface PCB 4

a) Replace PCB`4

5.11 Test Procedures

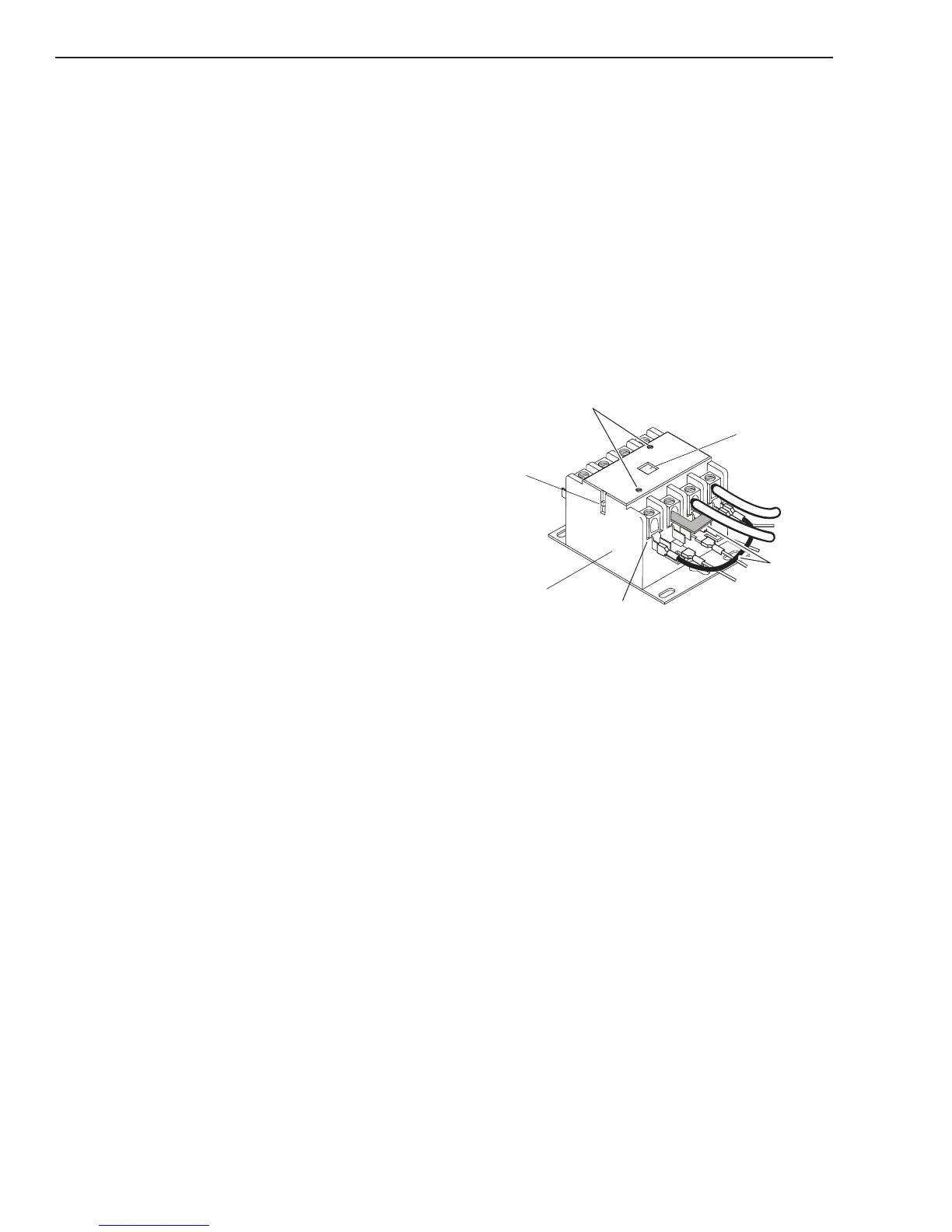

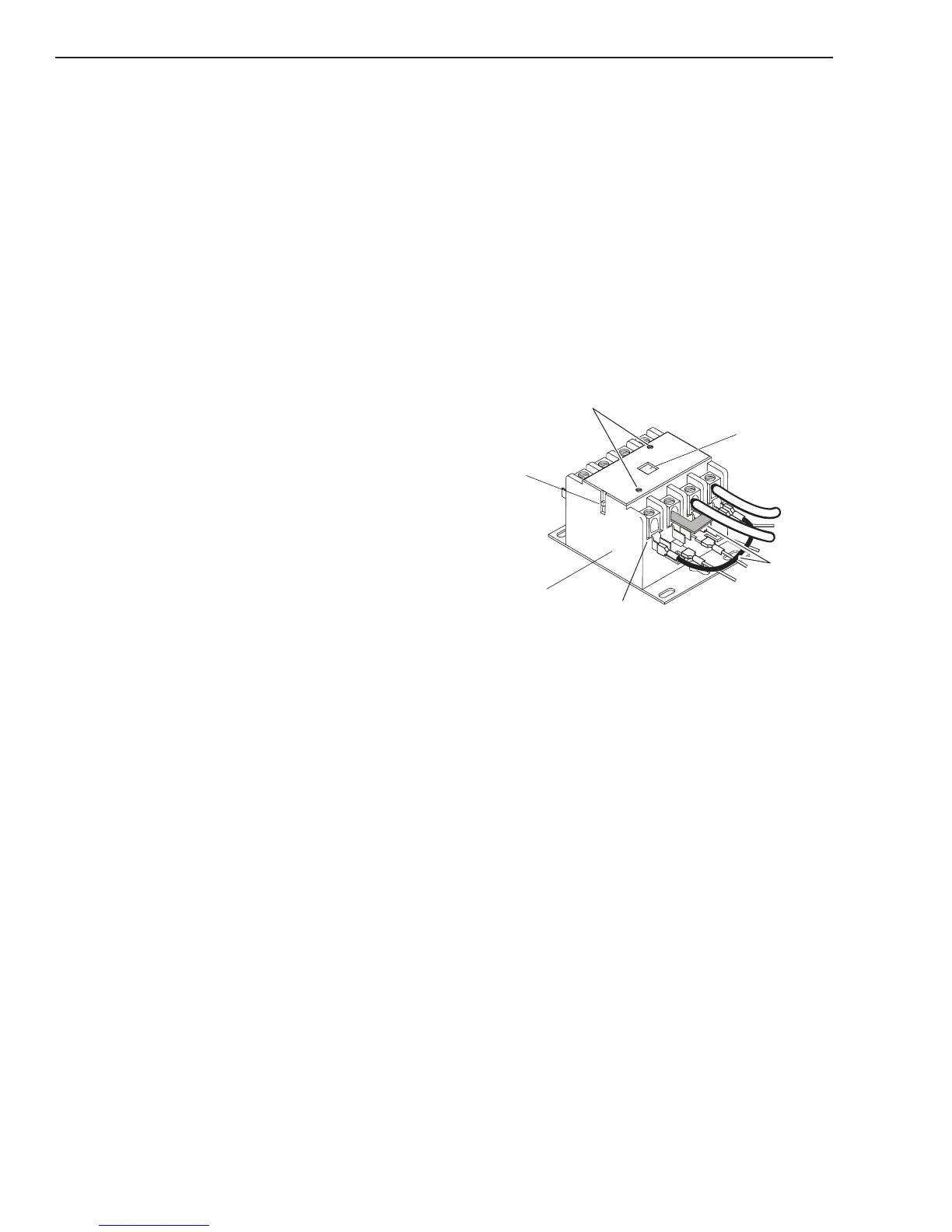

A. Main Contactor (W1) Test

1. Check continuity between:

L1 to T1

L2 to T2

L3 to T3

L4 to T4

The contacts should be open – no continuity. If con-

tinuity is found, disconnect J1 from the Main PCB 1

and recheck. If continuity still exists, replace W1. If

disconnecting J1 from Main PCB 1 removes the short,

replace the Main PCB 1.

L4

L3

L2

L1

T4

T3

T2

T1

Actuator Arm

Cover Screws

Art # A-08157_AB

Input

Side

CutMaster 52 & 82

W1 contactor wired for 1PH

Main Contactor

Jumpers

Actuator Button

2. Retest continuity between terminals while engag-

ing the contacts manually. This can be done by

pushing down on the recessed actuator button on

the top of W1 or pushing down on the actuator

arm on the side of W1.

L1 to T1

L2 to T2

L3 to T3

L4 to T4

The contacts should be closed – Continuity

3. Visually check W1 contact points. To take the

cover off, remove the two cover screws shown

in the previous illustration. If contacts are stuck

together or show excessive arcing or pitting, re-

place W1.

Loading...

Loading...