cutmaster 102

Manual 0-4998 5-21 SERVICE

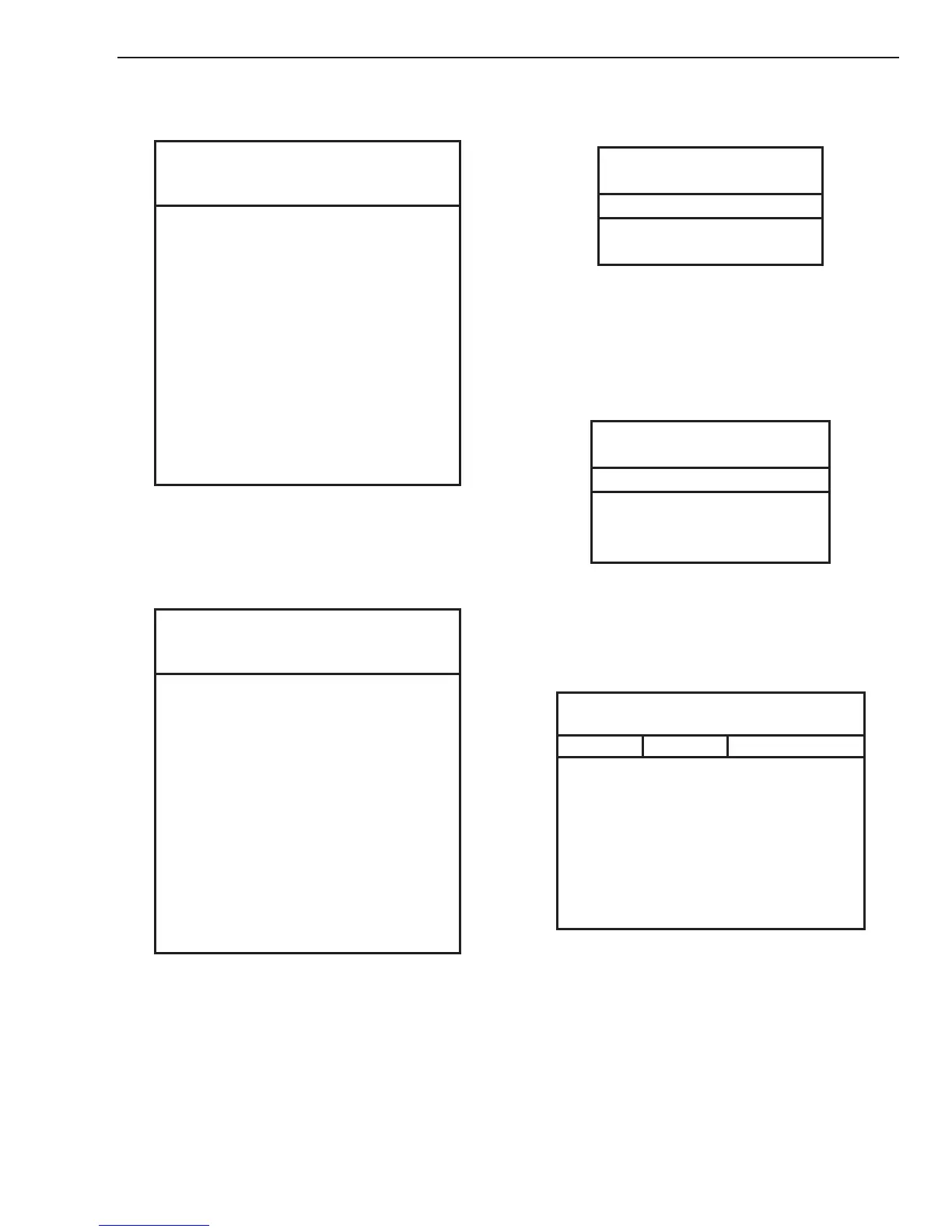

B. PCB 1 Input Diode D1Test

1. Using an ohmmeter perform the tests in the

chart:

Input Diode Module D1 on PCB1

Test points located on PCB 2

Meter (+) Meter (-) Indication

80A _AC1 MTH 1 Forward Biased Diode

80A_AC2 MTH 1 Forward Biased Diode

80A_AC3 MTH 1 Forward Biased Diode

MTH 1 80A_AC1 Reverse Biase Diode

MTH 1 80A_AC2 Reverse Biase Diode

MTH 1 80A_AC3 Reverse Biase Diode

MTH 7 80A_AC1 Forward Biased Diode

MTH 7 80A_AC2 Forward Biased Diode

MTH 7 80A_AC3 Forward Biased Diode

80A_AC1 MTH 7 Reverse Biase Diode

80A_AC2 MTH 7 Reverse Biase Diode

80A_AC3 MTH 7 Reverse Biase Diode

MTH 7 MTH 1 2 Forward Biased Diodes

C. PCB 5 Input Diode D1 Test

1. Using an ohmmeter perform the tests in the

chart:

Input Diode Module D1 on PCB5

Test points are located on PCB2

Meter (+) Meter (-) Indication

40A _AC1 PMTH 1 Forward Biased Diode

40A_AC2 PMTH 1 Forward Biased Diode

40A_AC3 PMTH 1 Forward Biased Diode

PMTH 1 40A_AC1 Reverse Biase Diode

PMTH 1 40A_AC2 Reverse Biase Diode

PMTH 1 40A_AC3 Reverse Biase Diode

PMTH 4 40A_AC1 Forward Biased Diode

PMTH 4 40A_AC2 Forward Biased Diode

PMTH 4 40A_AC3 Forward Biased Diode

40A_AC1 PMTH 4 Reverse Biase Diode

40A_AC2 PMTH 4 Reverse Biase Diode

40A_AC3 PMTH 4 Reverse Biase Diode

PMTH 4 PMTH 1 2 Forward Biased Diodes

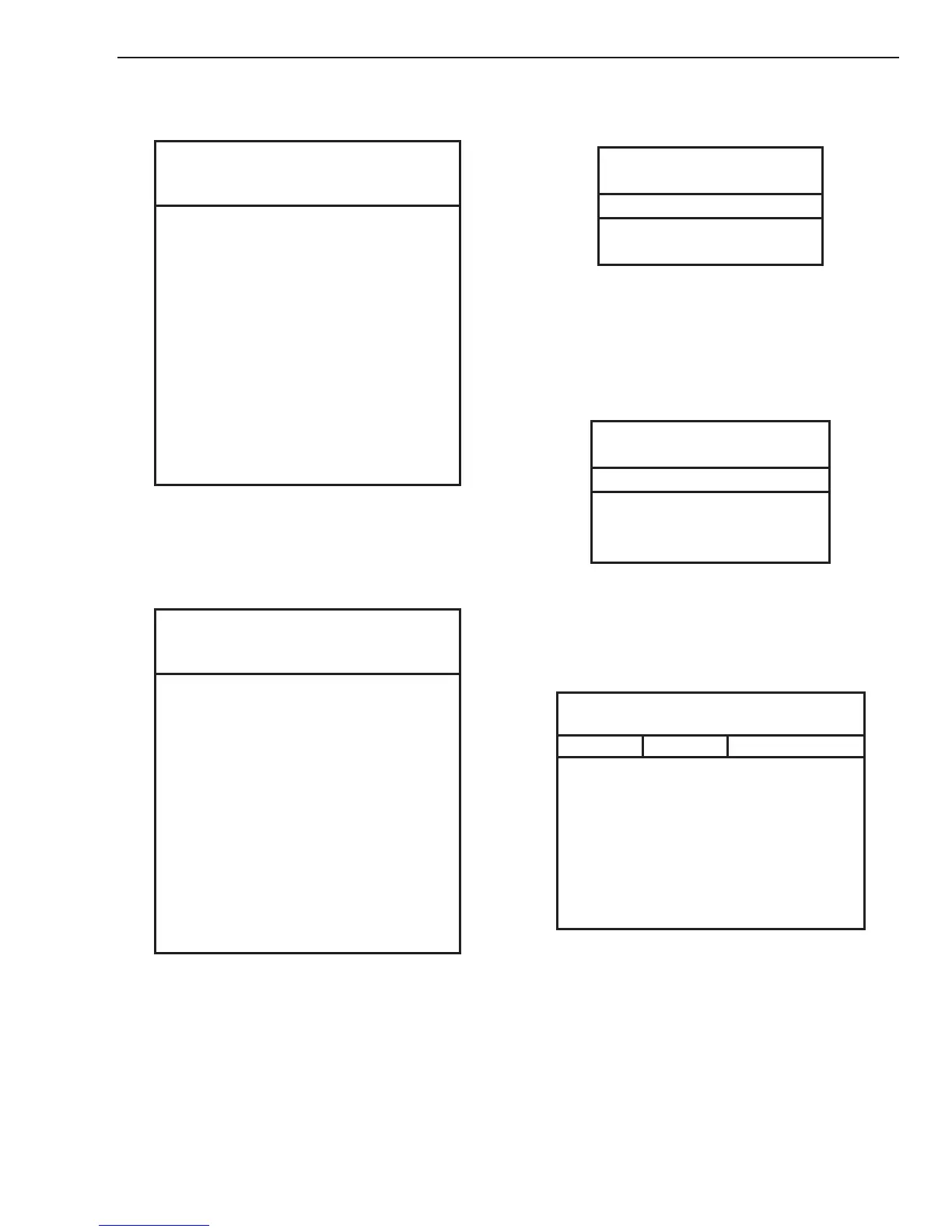

D. PCB 2 Capacitor / Relay Test

1. Using an ohmmeter perform the tests in the

chart:

INPUT CAPACITORS

PCB 2

Meter + Meter - Indication

MTH 2 MTH 4 Charging

MTH 8 MTH 7 Charging

Most meters will show a charging action. Initially a

low resistance will be shown and then the reststance

will start to increase. If the meter probews are re-

versed the reading will decrease to zero, then start

charging in the opposite polarity.

2. Using an ohmmeter perform the tests in the

chart:

INPUT VOLTAGE SELECTION RELAYS

PCB 2

Meter + Meter - Indication

MTH 7 MTH 4 Charging

MTH 8 MTH 2 Charging

MTH 8 MTH 4 Charging

E. PCB 1 IGBT Test

1. Disconnect transformer wire from PCB 2 Terminal

PRI1 (A).

2. Using an ohmmeter check continuity between the

following points:

PCB 1 Q1

Test points located on PCB 2

Meter (+) Meter (-) Indication

PRI 1 MTH 2 Forward Bias

PRI 1 MTH 4 Capacitor Charging

MTH 2 PRI 1 Capacitor Charging

MTH 4 PRI 1 Forward Bias

PRI 2 MTH 2 Forward Bias

PRI 2 MTH 4 Capacitor Charging

MTH 2 PRI 2 Capacitor Charging

MTH 4 PRI 2 Forward Bias

Loading...

Loading...