cutmaster 102

SERVICE 5-22 Manual 0-4998

3. Using an ohmmeter check continuity between the

following points:

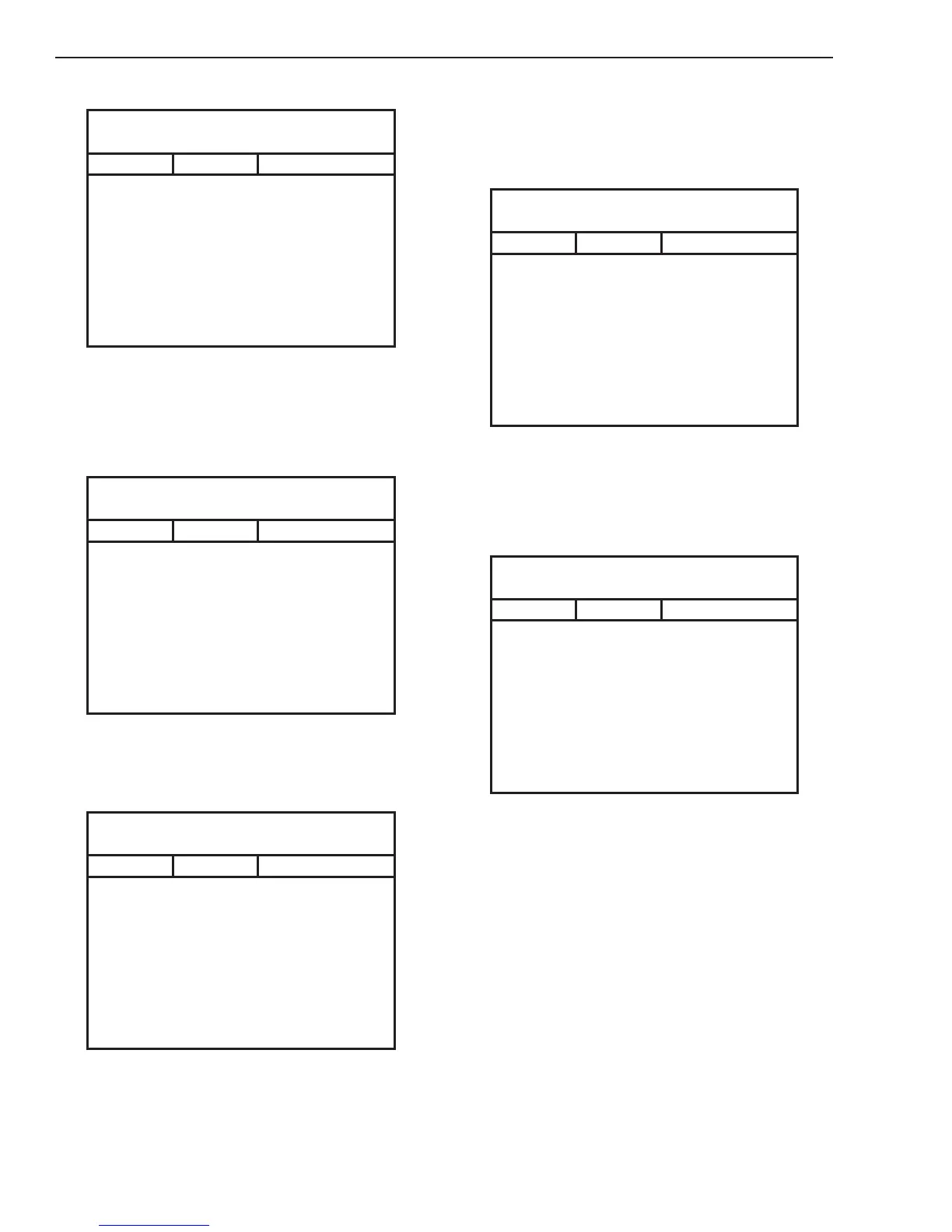

PCB 1 Q2

Test points located on PCB 1* & PCB 2

Meter (+) Meter (-) Indication

PRI 3* MTH 8 Forward Bias

PRI 3* MTH 7 Capacitor Charging

MTH 8 PRI 3* Capacitor Charging

MTH 7 PRI 3* Forward Bias

PRI 4* MTH 8 Forward Bias

PRI 4* MTH 7 Capacitor Charging

MTH 8 PRI 4* Capacitor Charging

MTH 7 PRI 4* Forward Bias

F. PCB 5 IGBT Test

1. Disconnect transformer wires from 40 Amp PCB

5 terminal PRI 1 (A).

2. Using an ohmmeter perform the following

checks:

PCB 5 - Q1

Test points located on PCB 2 AND PCB 5*

Meter (+) Meter (-) Indication

PRI 1* PMTH 1 Forward Bias

PRI 1* PMTH 2 Capacitor Charging

PMTH 1 PRI 1* Capacitor Charging

PMTH 2 PRI 1* Forward Bias

PRI 2* PMTH 1 Forward Bias

PRI 2* PMTH 2 Capacitor Charging

PMTH 1 PRI 2* Capacitor Charging

PMTH 2 PRI 2* Forward Bias

3. Disconnect transformer wire from 40 Amp PCB

5 terminal PRI4 (C).

4 Using an ohmmeter perform the following

checks:

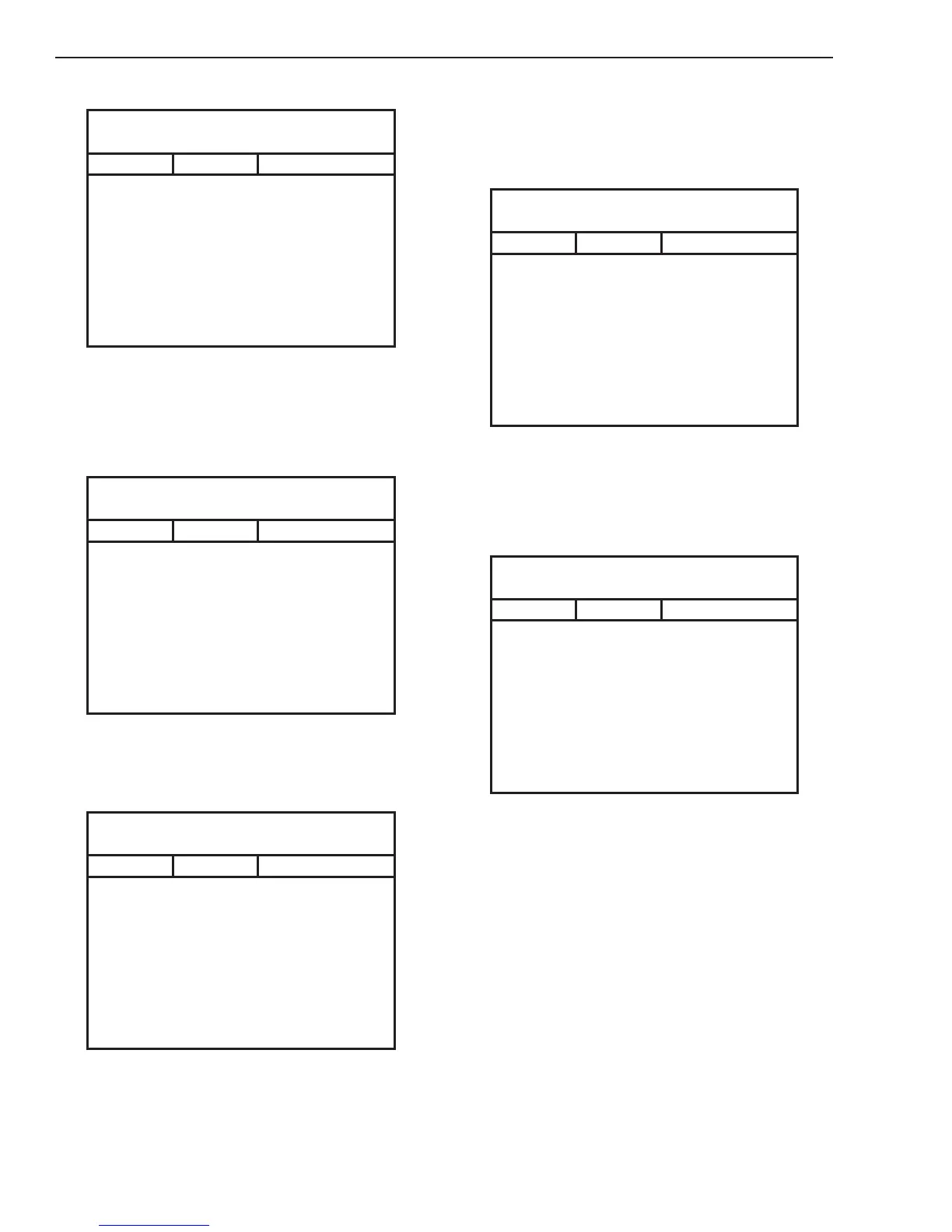

PCB 5 – Q2

Test points located on PCB 2 AND PCB 5*

Meter (+) Meter (-) Indication

PRI 4* PMTH 3 Forward Bias

PRI 4* PMTH 4 Capacitor Charging

PMTH 3 PRI 4* Capacitor Charging

PMTH 4 PRI 4* Forward Bias

PRI 3* PMTH 3 Forward Bias

PRI 3* PMTH 4 Capacitor Charging

PMTH 3 PRI 3* Capacitor Charging

PMTH 4 PRI 3* Forward Bias

G. PCB 1 Output Diode D3 Test

1. Disconnect transformer wires from Main PCB 1

terminal SEC1.

2. Using an ohmmeter perform the following

checks:

PCB 1 D3

(Test points located on PCB 1* & PCB 2)

Meter (+) Meter (-) Indication

CHOKE1 SEC1 Forward Bias

CHOKE1 SEC2 Forward Bias

SEC1 CHOKE1 Reversed Bias

SEC2 CHOKE` Reversed Bias

WORK1 SEC1 Reversed Bias

WORK1 SEC2 Reversed Bias

SEC1 WORK1 Forward Bias

SEC2 WORK1 Forward Bias

H. PCB 5 Output Diode D2 Test

1. Disconnect transformer wires from Main PCB 5

terminal SEC1.

2. Using an ohmmeter perform the following

checks::

PCB 5 – D2

Test points located on PCB 5

Meter (+) Meter (-) Indication

CHOKE1 SEC1 Forward Bias

CHOKE1 SEC2 Forward Bias

SEC1 CHOKE1 Reversed Bias

SEC2 CHOKE1 Reversed Bias

+OUT_1 SEC1 Reversed Bias

+OUT_1 SEC2 Reversed Bias

SEC1 +OUT_1 Forward Bias

SEC2 +OUT_1 Forward Bias

I. PCB 1 Pilot IGBT Test

1. Disconnect wire E35 from Main PCB 1 terminal

TIP1.

2. Using a mutlimeter with a diode test scale, place

the positive probe on PCB 1 terminal TIP1 and

the negative probe on PCB 1 terminal WORK1.

and check for a forward biased diode reading.

3. If the test reveals a failed component, replace

Main PCB 1. If no problem is found, reconnect

wire to Main PCB.

Loading...

Loading...