CUTMASTER 60i

Manual 0-5436 OPERATION

4T-1

SECTION 4 TORCH:

OPERATION

4T.01 Torch Parts Selection

Depending on the type of operation to be done deter-

mines the torch parts to be used.

Type of operation:

Drag cutting, standoff cutting or gouging

Torch parts:

Shield Cup, Cutting Tip, Electrode and Start

Cartridge

NOTE!

Refer to Section 4T.07 and following for ad-

ditional information on torch parts.

Change the torch parts for a different operation as fol-

lows:

WARNING

Disconnect primary power at the source

before assembling or disassembling torch

parts, or torch and leads assemblies.

NOTE!

The shield cup holds the tip and start

cartridge in place. Position the torch with

the shield cup facing upward to keep these

parts from falling out when the cup is

removed.

1. Unscrew and remove the shield cup assembly

from the torch head.

2. Remove the Electrode by pulling it straight out

of the Torch Head.

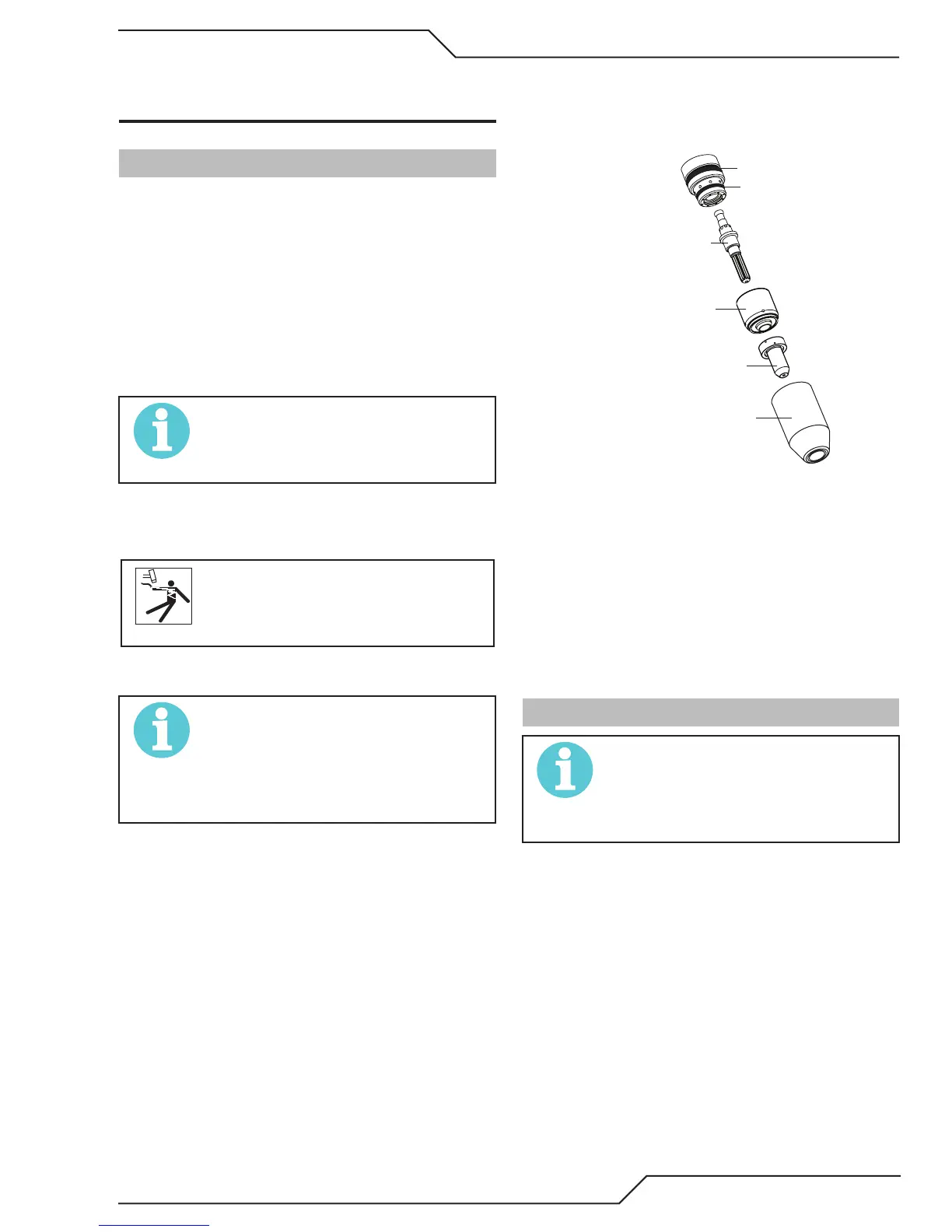

Electrode

Start Cartridge

Tip

Shield Cup

Torch Head

Large O-Ring

Small O-Ring

Torch Parts

3. Install the replacement Electrode by pushing it

straight into the torch head until it clicks.

4. Install the start cartridge and desired tip for the

operation into the torch head.

5. Hand tighten the shield cup assembly until it

is seated on the torch head. If resistance is felt

when installing the cup, check the threads before

proceeding.

4T.02 Cut Quality

NOTE!

Cut quality depends heavily on setup and

parameters such as torch standoff, align-

ment with the workpiece, cutting speed,

gas pressures, and operator ability.

Cut quality requirements differ depending on applica-

tion. For instance, nitride build - up and bevel angle

may be major factors when the surface will be welded

after cutting. Dross - free cutting is important when fin-

ish cut quality is desired to avoid a secondary cleaning

operation. The following cut quality characteristics are

illustrated in the following figure:

Loading...

Loading...