INSTALLATION PROCEDURES 3-2 Manual 0-2815

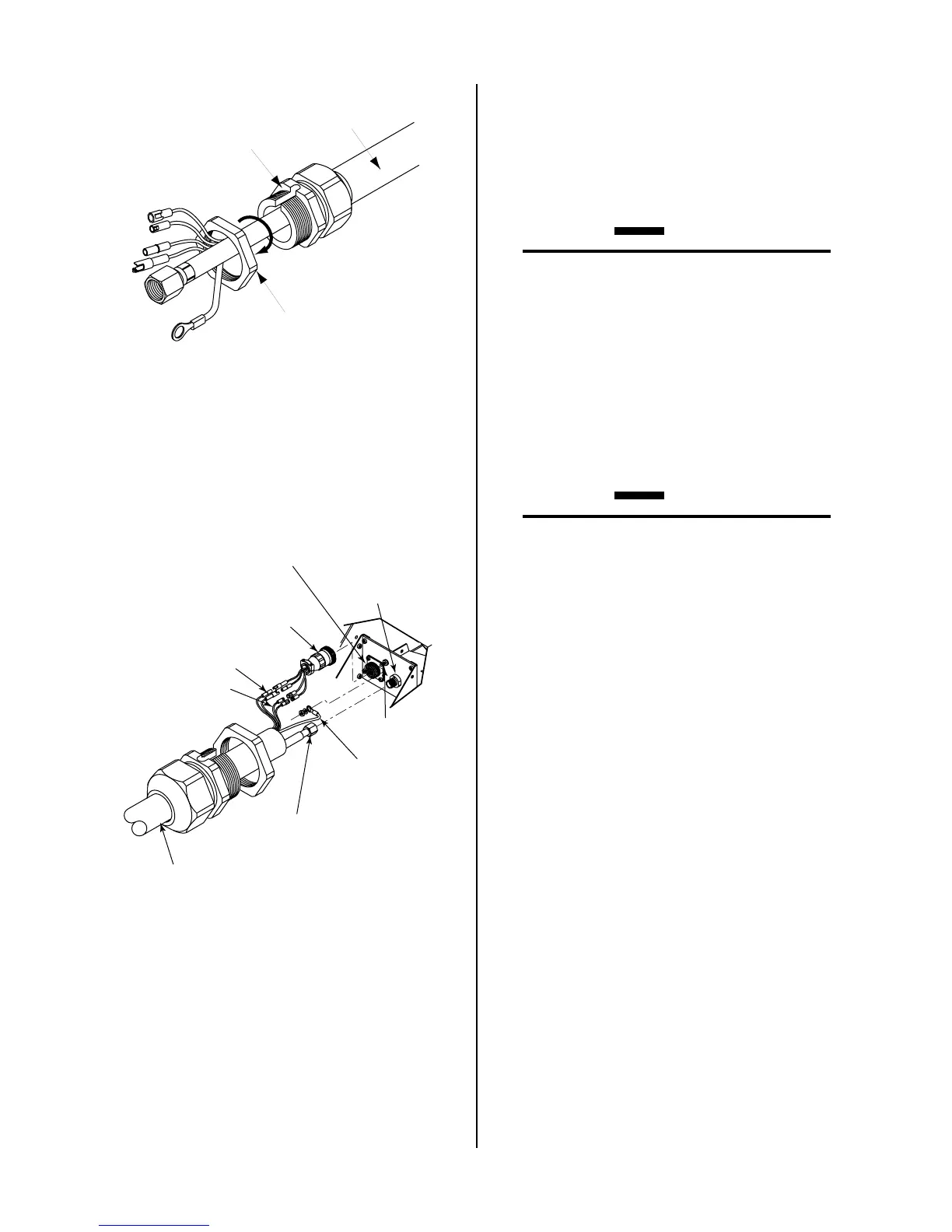

Strain Relief

Nut

Strain Relief

Torch Leads

Assembly

A-02826

Figure 3-2 Strain Relief Nut Removal

2. Feed the torch lead ends and the Strain Relief into

the hole in the unit.

3. Secure the Strain Relief with the retaining nut re-

moved earlier.

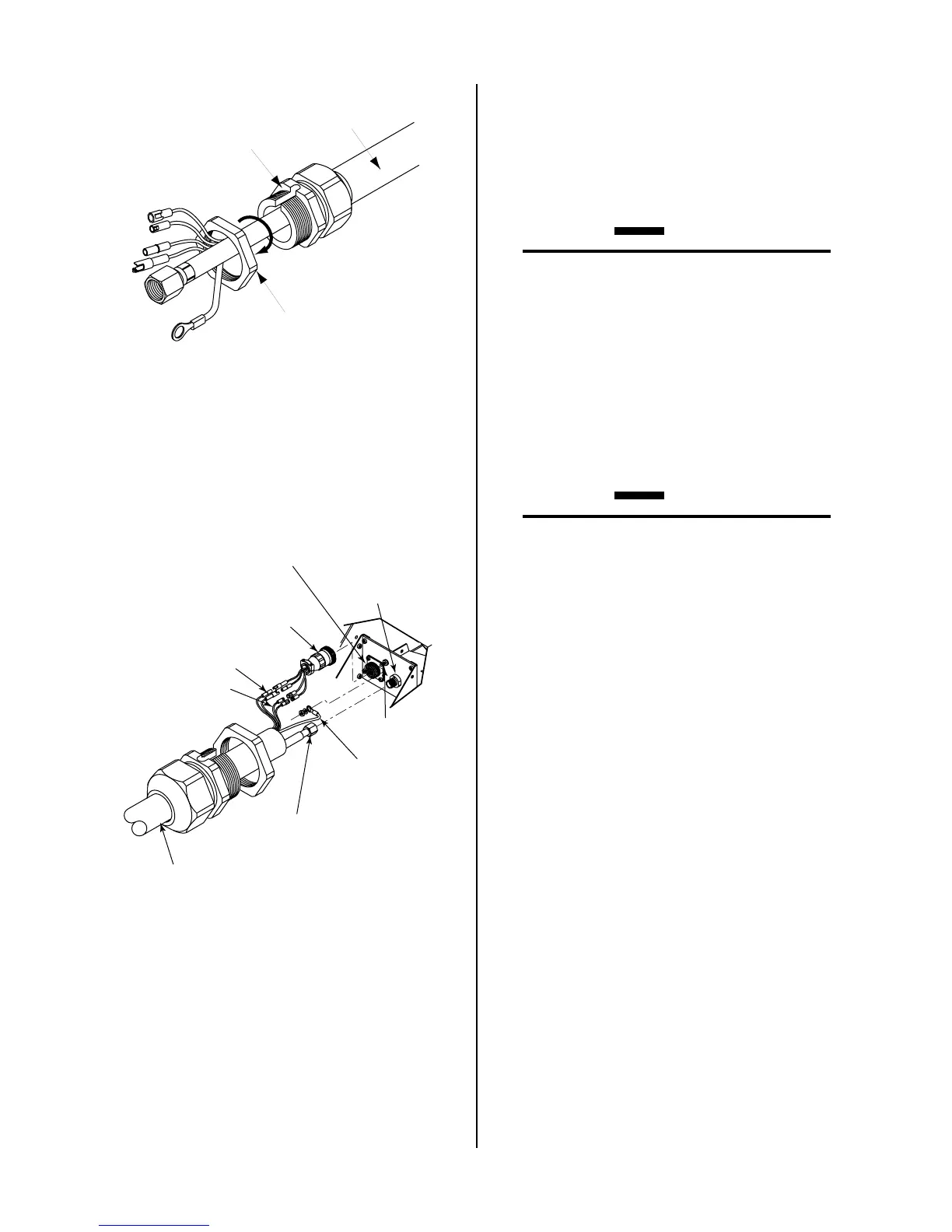

Adapter

(Supplied With

Power Supply)

Pilot Lead

Torch Lead

Assembly

Negative/Plasma

Lead

Adapter Connector

Pilot Lead

Stud

Negative/Plasma

Lead Connection

A-02831

Control (PIP) Circuit

Connectors

Shield Connectors

Figure 3-3 Torch Lead Connections

4. Connect the torch Negative/Plasma Lead to the

bulkhead connection inside the Power Supply.

5. Connect the PIP and Shield Cables to the mating

connectors on the Adapter supplied on the Power

Supply.

6. Remove the top nut and washer from the Pilot

Stud.

7. Place the lug on the Pilot Control Wire onto the

stud and secure with the nut and washer removed

in the above Step.

8. Tighten the Strain Relief onto the Torch Leads.

9. Check the torch for proper parts assembly.

CAUTION

The torch parts must correspond with the type of

operation. Refer to Section 4.04, Torch Parts Se-

lection.

3.06 Gas Connection

A. Connection

Connect the gas , compressed air or nitrogen (N2)

only, to the Power Supply as described in the Manual

supplied with the Power Supply.

CAUTION

Air supply must be free of oil, moisture, and other

contaminants. Excessive oil and moisture may

cause double-arcing, rapid tip wear, or even com-

plete torch failure. Contaminants may cause poor

cutting performance and rapid electrode wear.

B. Checking Air Quality

To test the quality of air, place a welding filter lens in

front of the torch and turn on the gas. Any oil or

moisture in the air will be visible on the lens. Do not

initiate an arc!

C. Filtering

An in-line pneumatic dryer/evaporator type air fil-

ter, capable of filtering to at least 5 microns, is required

when using air from a compressor. This type filter

will insure that moisture, oil, dirt, chips, rust particles,

and other contaminants from the supply hose do not

enter the torch. For highly automated applications,

a refrigerated drier may be used.

Loading...

Loading...