MP-3000 Controller

83

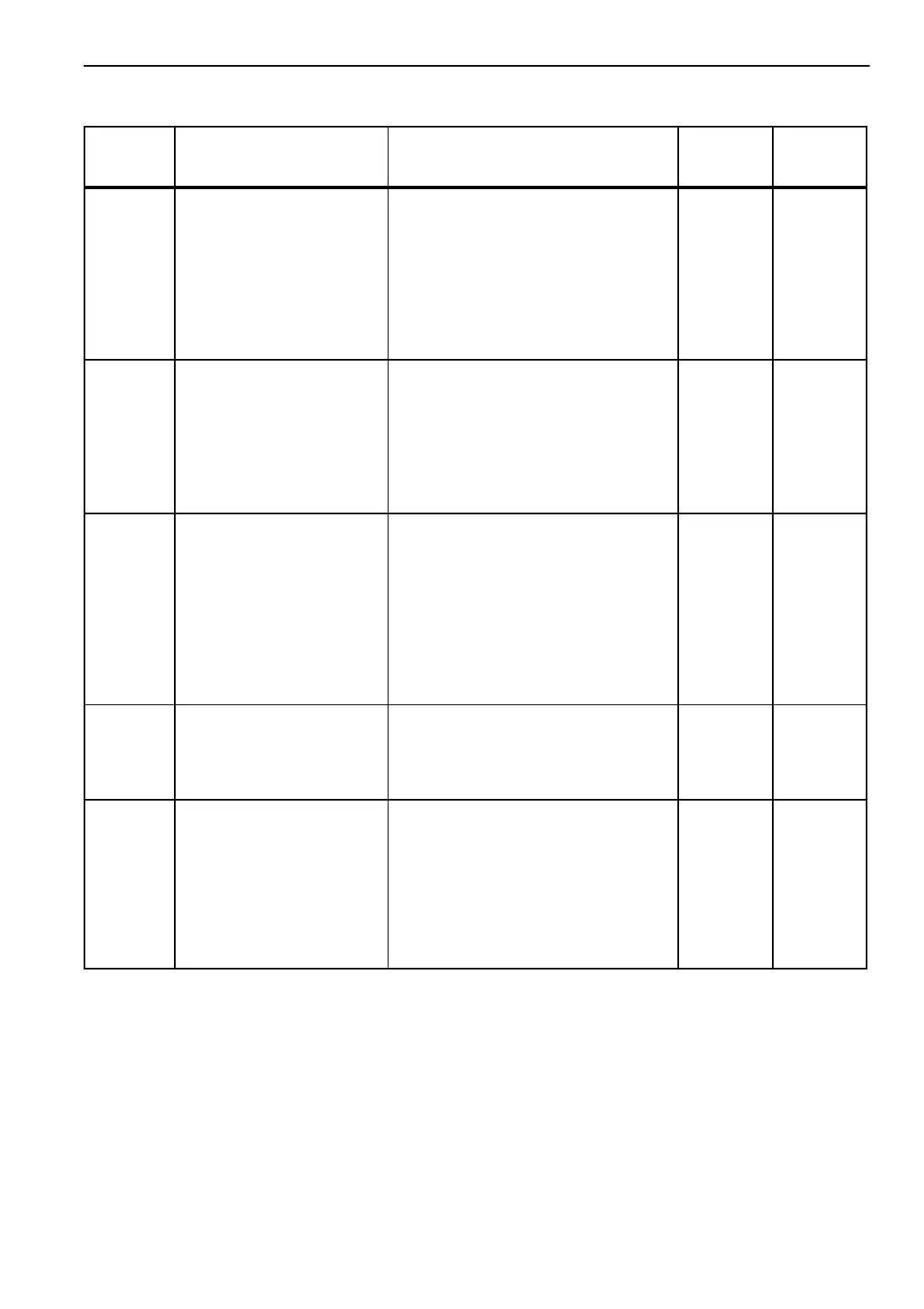

F1.07

Injection Valve Test

Activated

7.6 A 7.5 A 7.6 A

Condenser fan and compressor remain

on. Liquid injection valve is turned on.

Amp draw is measured and verified to be

a minimum of 0.1 amps higher that test

F1.06.

NOTE: If the condenser fan is off

for test F1.06, the fan remains off

for this test.

29, 31 10 Seconds

F1.08

Low Pressure Test

Activated

0.8 A 0.7 A 0.8 A

Condenser fan, compressor and liquid

injection valve remain on. Stepper valve

is closed and low pressure cutout is

verified to open.

NOTE: If the condenser fan is off

for test F1.06, the fan remains off

for this test.

31 10 Seconds

F1.09

Warm Gas Bypass

Valve Activated

8.3 A 8.2 A 8.3 A

With condenser fan and compressor on,

compressor is operated at 25% capacity.

Liquid injection valve is off. Bypass valve

is turned on. Amp draw measured and

verified to be a minimum of 0.2 amps

higher that test F1.06.

NOTE: If the condenser fan is off

for test F1.06, the fan remains off

for this test.

F1.10

Heat Test

Activated

5.2 A 5.1 A 5.2 A

Amp draw is measured and compared to

voltage:

• 4.4 Amps approx. at 400V

• 5.1 Amps approx. at 460V

10, 11 10 Seconds

F1.11

Humidify Valve Test

Activated

0.1 A 0.0 A 0.1 A

Coil/Dehumidify valve is turned on for

2 seconds, off for 2 seconds and on for 2

seconds to verify valve operation.

Function test log ends.

Alarms (if any) are cleared from

datalogger. However, alarms (if any)

remain in alarm list as not active until

acknowledged.

None 6 Seconds

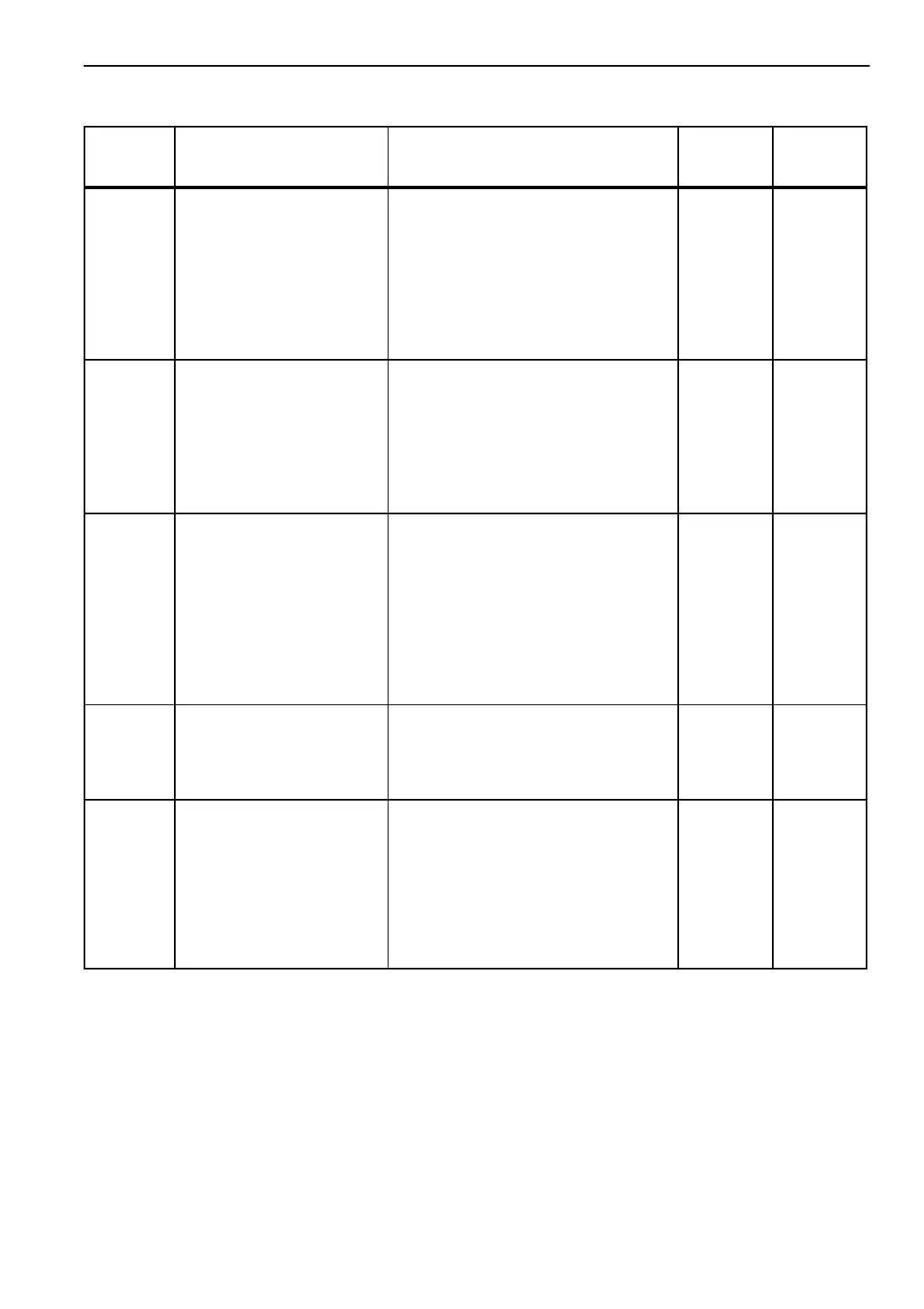

CSR & Function Test Procedure (Continued)

LED

Display

(Test No.)

LCD Display

(Shows Approx. Amps for

460V, 60 Hz Unit)

Test Description

Possible

Alarms

Duration

(Time)

Loading...

Loading...