MP-3000 Controller

86

P1.11

Low Pressure Test

Activated

0.8 A 0.7 A 0.8 A

Condenser fan, compressor and liquid

injection valve remain on. Stepper valve is

closed (set to 100 value) and low

pressure cutout is verified to open.

31 10 seconds

P1.12

Warm Gas Bypass

Valve Activated

8.3 A 8.2 A 8.3 A

With condenser fan and compressor on,

compressor is operated at 25% capacity.

Liquid injection valve is off. Bypass valve

is turned on. Amp draw measured and

verified to be a minimum of 0.2 amps

higher that test P1.09.

30 10 seconds

P1.13

Compressor High Pressure

Activated

12.2 A 12.0 A 12.2 A

Stepper valve opened to 50% capacity.

With compressor on, evaporator fan

operates on high speed until high

pressure cutout occurs, causing

significant amps drop. Maximum time

depends on condenser coil temperature

at start of test.

53

10 to 300

Seconds

P1.13

Compressor High Pressure

Activated

4.5 A 4.4 A 4.5 A

With compressor off, condenser fan starts

and operates until compressor starts,

causing a significant amps increase.

Compressor is then turned off. Condenser

fan operates 60 seconds more to lower

condenser temperature.

54

10 to 50

Seconds

plus 60

Seconds

P1.14

Evaporator Fan Low

Activated

1.1 A 1.0 A 1.1 A

Condenser fan and compressor are

turned off. With evaporator fan on low

speed, Amp draw is measured and

compared to voltage and frequency:

• CSR40:

1.0 Amps approx. at 50 Hz,

1.0 Amps approx. at 60 Hz

• CSR20SL and CSR40SL:

1.5 Amps approx. at 50 Hz,

1.6 Amps approx. at 60 Hz

Evaporator fan low amperes are recorded

in the PTI log.

14, 15 10 Seconds

P1.15

Capacity Test 1

Activated

12.1 A 12.0 A 12.1 A

With condenser fan on, compressor on,

and evaporator fans on low speed,

stepper valve is set to 50% capacity.

Liquid injection valve is turned on. A

difference of approx. 4.5 C (8.0 F) is

required between return and supply air

temperatures, depending on return air

and condenser coil temperatures.

22

3 Minutes

(4 Minutes

on CRR20)

P1.16

Capacity Test 2

Activated

13.2 A 13.0 A 13.2 A

With condenser fan on, compressor on,

liquid injection valve on and stepper valve

set to 50% capacity, evaporator fans are

changed to high speed. A difference of

approx. 3.0 C (5.4 F) is required between

return and supply air temperatures,

depending on return air and condenser

coil temperatures. However, temperature

difference must be less than in test P1.15.

23 2 Minutes

CSR Pre-trip (PTI) Test Procedure (Continued)

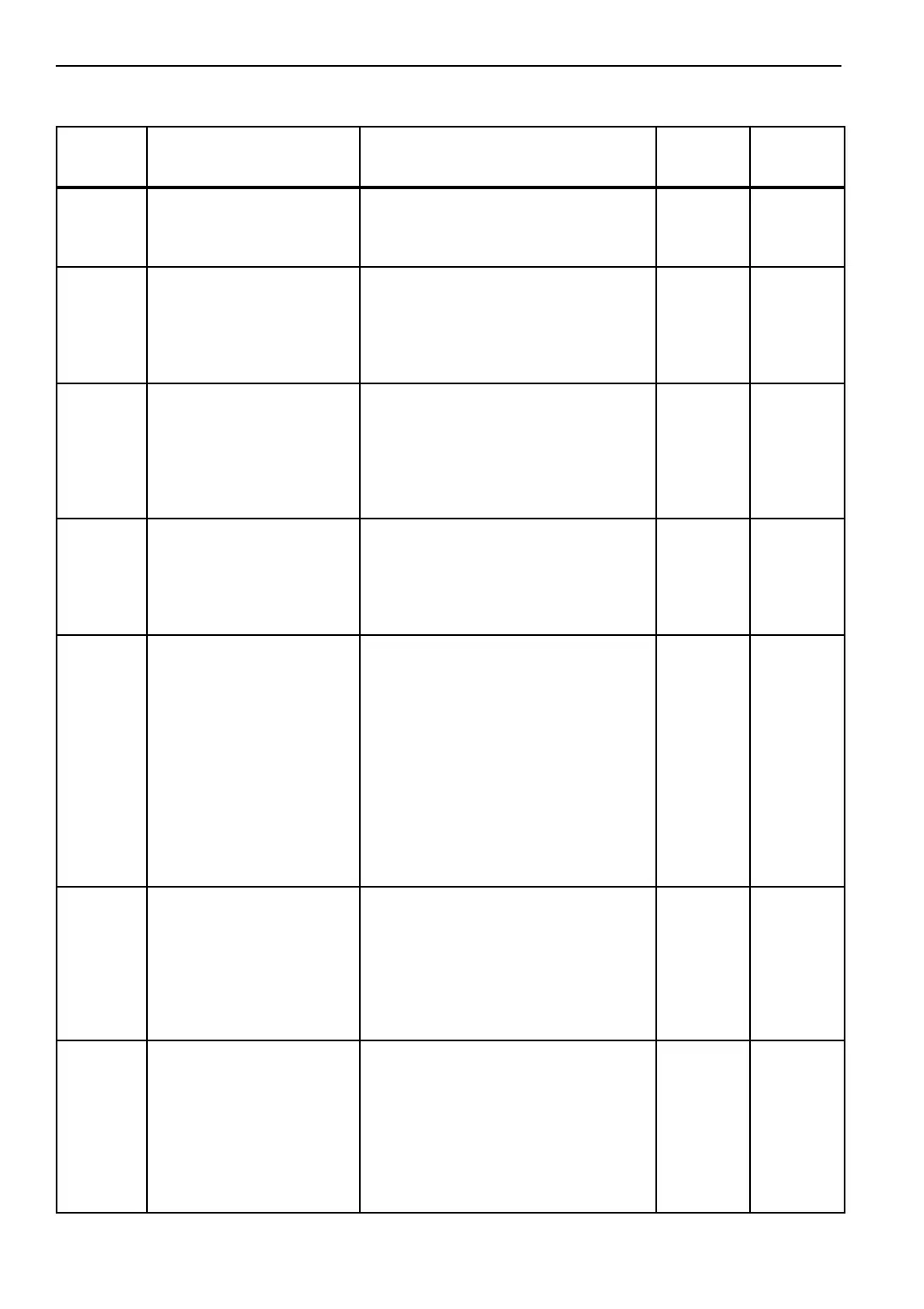

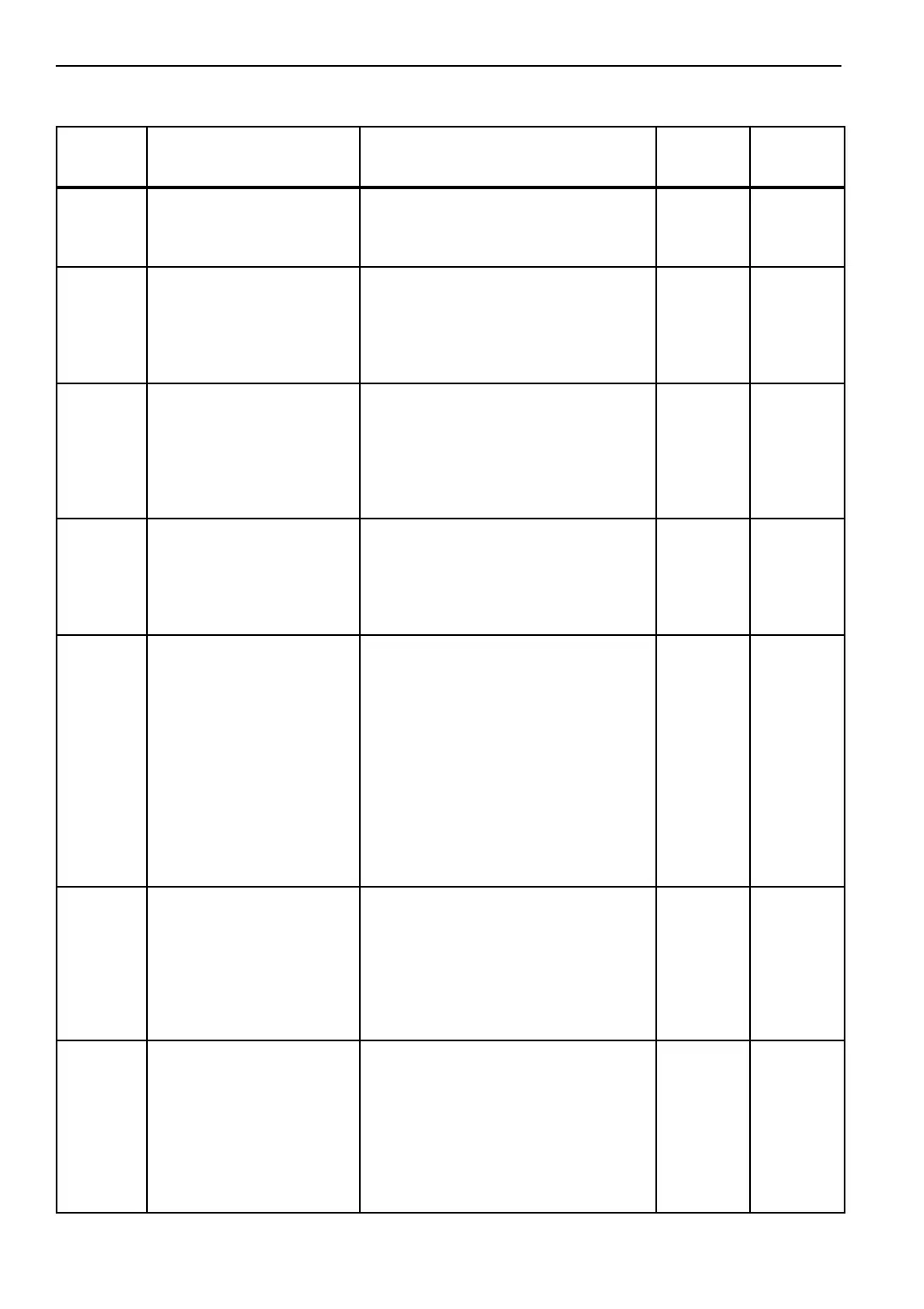

LED

Display

(Test No.)

LCD Display

(Shows Approx. Amps for

460V, 60 Hz Unit)

Test Description

Possible

Alarms

Duration

(Time)

Loading...

Loading...