WARNER ELECTRIC EUROPE - Rue Champfleur, B.P. 20095, F - 49182 St Barthélemy d’Anjou Cedex SM342gb - rev 01/06 4/5

Caution: When installing and should the brake ever be

dismantled, make sure that the friction disc heel is the right

way round when the brake is re-assembled (see Fig.1).

• Engage the brake (line up the brake on the fixing thread)

• Tighten the 8 fixing screws CHc M12 (star sequence

tightening, Cs: 50 Nm). Finish tightening with a torque,

76 Nm (±10%)

NOTE: Secure the fixing screws (use a safety washer or

thermoplastic liquid such as Loctite).

• Remove the 3 transport screws

• Make all the electrical connections

4 Maintenance

4.1 Adjusting the airgap

Reminder: This brake is intended for a static

application as a safety brake. Any dynamic braking

is restricted to emergency and test braking. Normal use will

not lead to any noticeable wear on the lining. If for any

reason it should be necessary to adjust the airgap, proceed

as follows:

Loosen the attachment screws slightly. Adjust airgap

(Fig. 3) with adjusting screws (hexagonal bar 21/flat) until

they slightly exceed the nominal value (see Table 1). Tighten

the screws (refer to point 3.3 Installation). Carry out a few

successive draws and releases. Check the value of the

airgap at several points. Repeat the whole process if

necessary.for the second.

4.2 Adjusting the microswitch

Slide a wedge 0,15 mm thick close to the screw between

the face of the magnet and the moving armature. Switch

on the current and tighten the adjusting screw H M4 (7/flat)

in contact with the microswitch until you reach the com-

mutation point. Remove the disc or the wedge. Check that

it functions correctly by a few successive draws and

releases.

Operation microswitch

Current range 10 mA min. to 100 mA max. at 24 VDC.

Maximum electrical lifetime of the microswitch ensure only

by switching under resistive load.

Microswitch

connection

When the coil is switched off, the microswitch is in the "

NC " position.

5 Electrical connection

Brake ERS VAR08 SZ 1700/1700 Warner Electric part

number 1 12 106606 operates on a direct current sup-

ply. Polarity does not affect the way the brake operates.

5.1 Important recommendations

All works on the electrical connections have to be

made with power off.

Make sure that the nominal supply voltage is always

maintained. A lack of power results in a reduction

to the maximum airgap

Emergency braking : for emergency braking the

switching OFF must be connected on DC current

side, in order to obtain short engaging time of the brake

Service braking : for service braking, the switching OFF

and the switching ON must be connected on AC current

side, in order to obtain silent switching.

The connecting wires must be thick enough to help prevent

sudden drops in voltage between the source and the brake.

Tolerances on the supply voltage at the brake terminals

+5% / -10% (NF C 79-300).

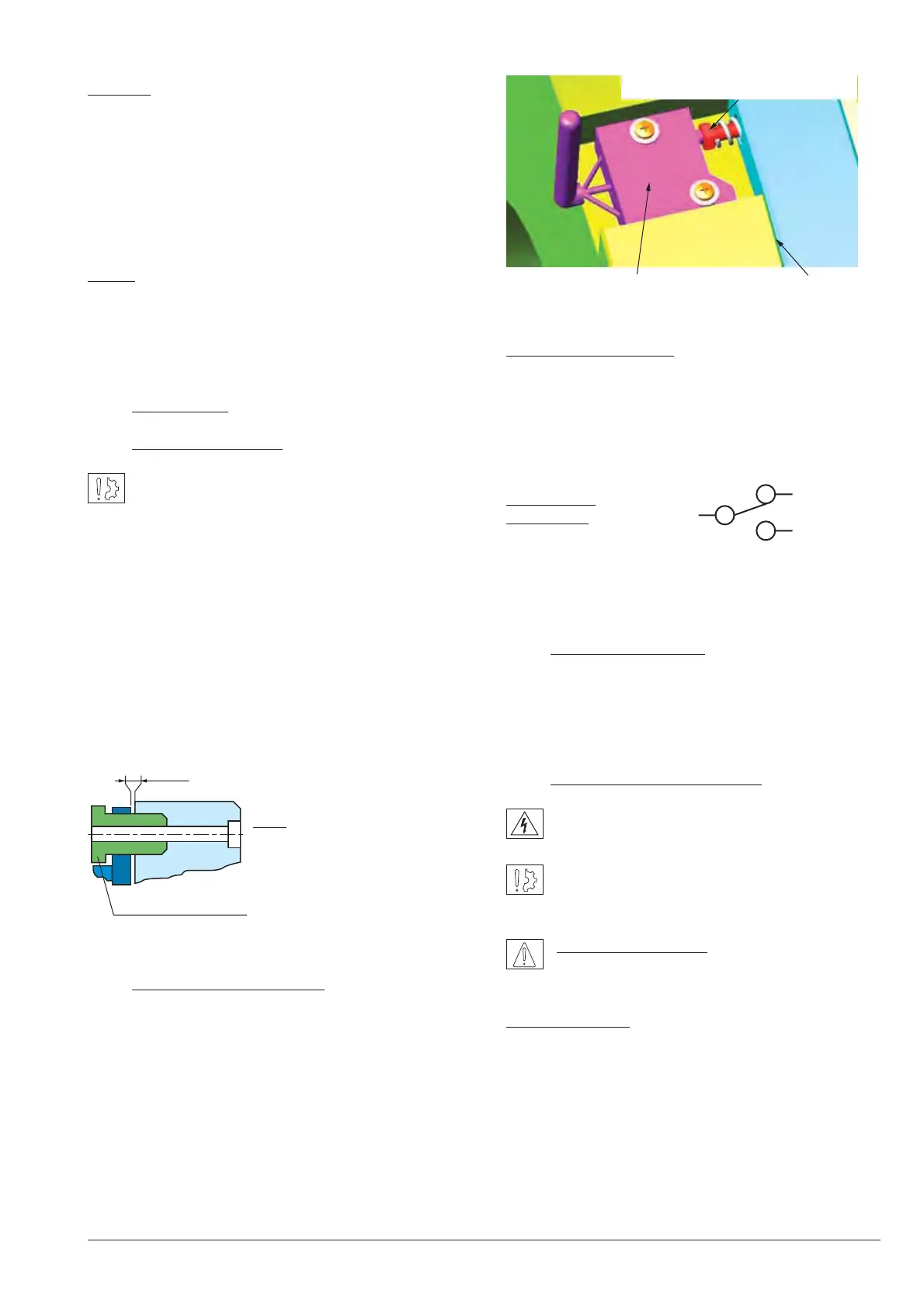

Fig. 3

Fig. 4

Loading...

Loading...