Installation and Operational Instructions

for ROBA-stop

®

-silenzio

®

Type 896.213.30

Sizes 500 – 1800

Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0 E079 10 228 000 471

Eichenstraße 1 Fax: +49 8341 804-421 Page 10 of 17

D-87665 Mauerstetten www.mayr.com

Germany E-Mail: info@mayr.com 21/06/2012 TK/HW/GF/SU

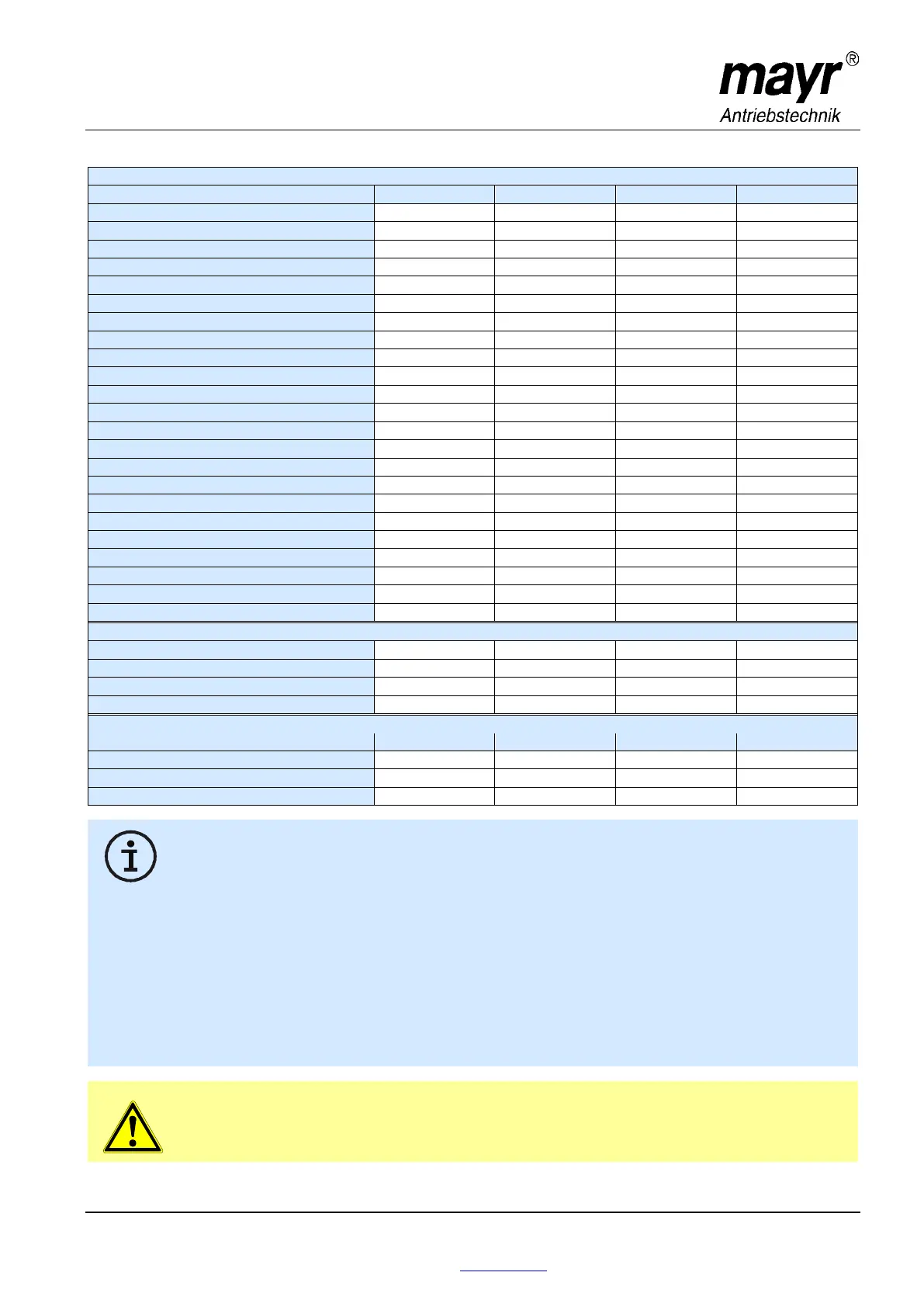

Technical Data

Coil power (at nominal voltage):

Coil power (on overexcitation):

Permitted friction work per braking:

Rotor thickness, new condition:

Nominal air gap "a" (-0,1 mm / +0,15mm):

Individual air gaps "b" released:

Tightening torque Item 7:

Duty cycle with 180 switchings/h:

Electrical connection (coil):

Electrical connection (microswitch):

Switching Times in New Condition

Response delay on connection t

11

(AC):

Switching Times acc. TÜV (German Technical Inspectorate) Type Examination Certificate Amendment 3

1)

The braking torque (nominal torque) is the torque effective in the shaft train on slipping brakes with a sliding speed

of 1 m/s referring to the medium friction radius.

For stabilisation of the friction conditions, a run-in process in new condition is recommended.

2)

Once the maximum air gap has been reached, the rotors must be replaced.

However, the brake already becomes louder at an air gap > "a" +0,2 mm.

3)

Referring to the effective braking torque on switch-off from holding voltage (nominal voltage)

4)

Referring to the nominal braking torque on switch-off from 2 times the holding voltage (overexcitation)

The stated switching times can only be achieved using the respective correct electrical wiring. This also refers to the protective circuit

for brake control and the response delay times of all control components. If the brake is operated using overexcitation, the respective

switch-on and switch-off times for overexcitation must be taken into account (inadvertent movements of the elevator cage).

The use of varistors for spark quenching increases the DC-side switching times.

At temperatures of around or under freezing point, condensation can strongly reduce the braking torque. The user is responsible for taking

appropriate counter measures. The customer is responsible for providing a protective cover against contamination caused by construction

sites.

On brake operation with overexcitation, there is a possibility of possibly unpermitted braking torque reduction when the air

gap "a" > maximum air gap.

Loading...

Loading...