Installation and Operational Instructions

for ROBA-stop

®

-silenzio

®

Type 896.213.30

Sizes 500 – 1800

Chr. Mayr GmbH + Co. KG Tel.: +49 8341 804-0 E079 10 228 000 471

Eichenstraße 1 Fax: +49 8341 804-421 Page 11 of 17

D-87665 Mauerstetten www.mayr.com

Germany E-Mail: info@mayr.com 21/06/2012 TK/HW/GF/SU

Application

ROBA-stop

®

-silenzio

®

for use as a holding brake with

occasional EMERGENCY STOP braking actions

Horizontal brake axis.

The max. permitted speed and friction work values, see

Technical Data, must be observed.

Design

The ROBA-stop

®

-silenzio

®

is a spring applied,

electromagnetically releasing safety brake.

It is designed for installation into gear elevator machines for use

as a holding brake with occasional EMERGENCY STOP braking

actions.

On dimensioning, the braking torque, the speed as well as the

permitted friction work in case of EMERGENCY STOP need to

be taken into consideration for safe holding of the load torque

and safe compliance with the required braking distance.

Furthermore, the ROBA-stop

®

-silenzio

®

can be used as a brake

assembly having an effect on the drive sheave shaft, as part of

the protective assembly against excessive upward-moving cage

speeds (EN 81-1 Section 9.10.2).

Please observe the appendix (application range, conditions,

guidelines) in the EC Type Examination Certificate (EC directive

95/16/EC).

Moreover, the brake fulfils all criteria as a brake element having

an effect on the drive sheave shaft, as part of the protective

assembly against inadvertent movement of the elevator cage

(EN 81-1 Section 9.11.3).

Here, please observe the notes in the appendix (application,

area, conditions, guidelines) of the Type Examination Certificate

(inspection specification EN 81-1:1998+A3:2009(D))

In order to guarantee the maximum braking distance (EN 81-1

Section 9.11.5) while both brakes take effect, an inspection of

the protective equipment including all controls and brake times

(detector / controls / brake) is necessary. The respective

standards, regulations and directives must be observed.

Function

ROBA-stop

®

-silenzio

®

brakes are spring applied,

electromagnetic safety brakes.

Spring applied function (brake):

In de-energised condition, thrust springs (10/11) press against

the armature disk (3). The rotor 2 (4.1) is held between the

armature disk (3) and the intermediate disk (12), the rotor 1 (4)

between the intermediate disk (12) and the machine wall via

frictional locking. The braking torque is introduced into the shaft

via the rotor toothing (4 and 4.1) and the hub (1).

Electromagnetic function (release):

Due to the magnetic force of the coil in the coil carrier (2), the

armature disk (3) is attracted against the spring force to the coil

carrier (2) and the intermediate disk (12) is pressed against the

collar of the distance bolts (9) via the thrust springs (13).

The brake is released and the brake rotors (4 and 4.1) with the

hub (1) can rotate freely.

Safety brake function:

The ROBA-stop

®

-silenzio

®

brakes reliably and safely in the event

of a power switch-off, a power failure or an EMERGENCY

STOP.

State of Delivery

The brakes are pre-assembled.

The release monitoring devices (6) are mounted and set

manufacturer-side.

Included loose in delivery are:

- Hub (1)

- Rotor (4)

- Cap screws (5.1)

- Washers (5.2)

- Hexagon head screws (7)

- Washers (8)

- Thrust springs (13)

- Cover plate (14)

- Cap screws (15)

Please check the state of delivery immediately according to the

Parts List.

mayr

®

will take no responsibility for belated complaints.

Please report transport damage immediately to the deliverer.

Please report incomplete delivery and obvious defects to the

manufacturer.

The screws (16) marked red must be removed

before initial operation of the brake.

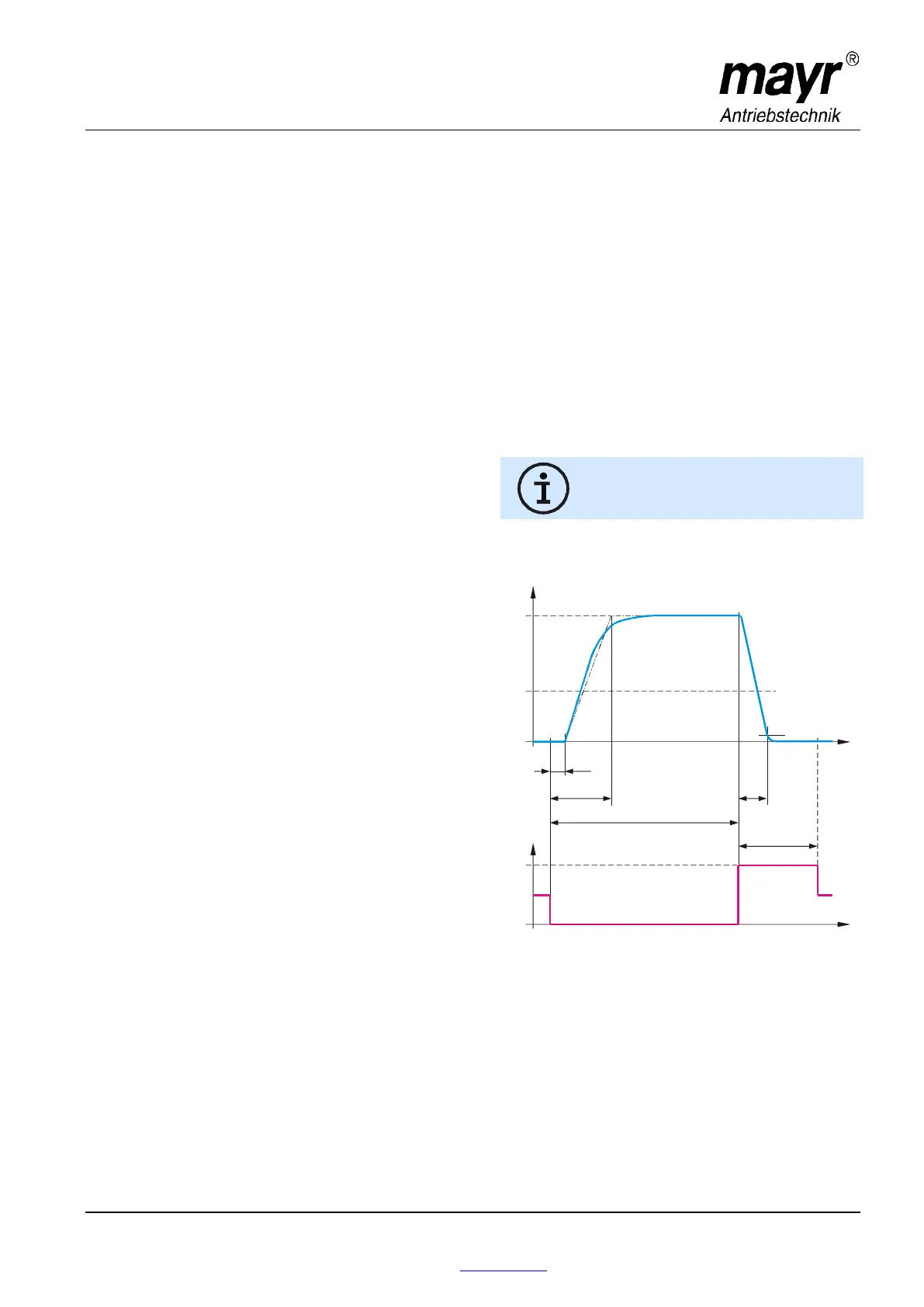

Torque-Time Diagram

Key

M

Br

= Braking torque

M

L

= Load torque

t

1

= Connection time

t

11

= Response delay on connection

(≙t

0

acc. ESV 762/1)

t

2

= Separation time

t

4

= Slipping time + t

11

t

über

= Overexcitation time

U

nenn

= Coil nominal voltage

U

halte

= Holding voltage

U

über

= Overexcitation voltage

U

halte

U

über

M

Br

0,1 x M

Br

M

L

t

11

t

1

t

2

t

4

t

über

U

M

t

t

Loading...

Loading...