5-44

Power Unit

4st 9.9/15/20 2008

30)

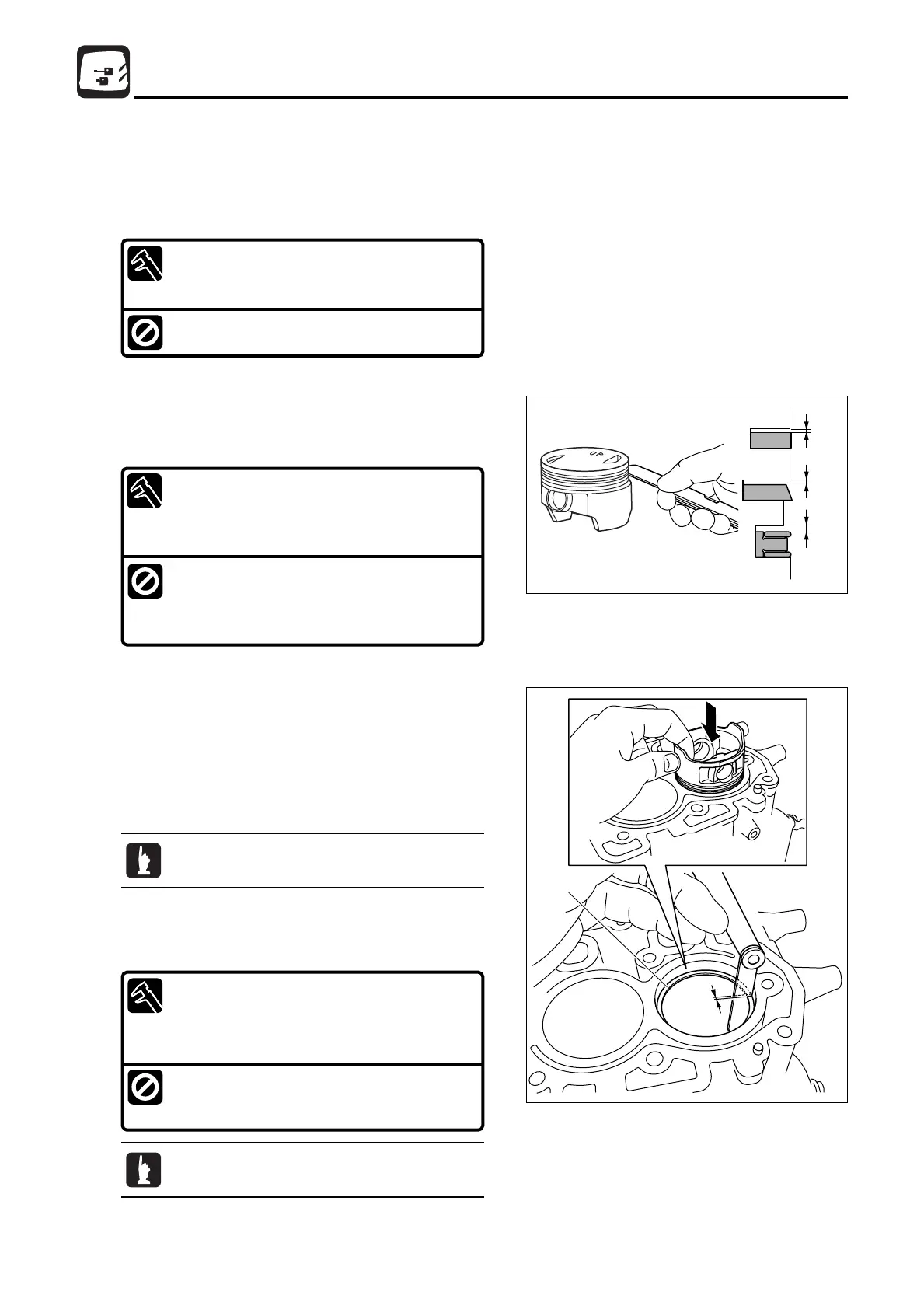

Inspection of Piston Ring Side Clearance

1. Measure piston side clearance. Replace piston and piston

rings as a set if the clearance is over specified value.

Piston Ring Side Clearance :

Top Ring a : 0.04 - 0.08mm (0.0016 - 0.0031 in)

Second Ring b : 0.03

-

0.07mm (0.0012

-

0.0028 in)

Oil Ring c : 0.05

-

0.15mm (0.0019

-

0.0059 in)

Functional Limit :

Top Ring a : 0.10 mm (0.0039 in)

Second Ring b : 0.09 mm (0.0035 in)

Oil Ring c : 0.17 mm (0.0067 in)

Replace oil ring when top ring or second ring is

replaced.

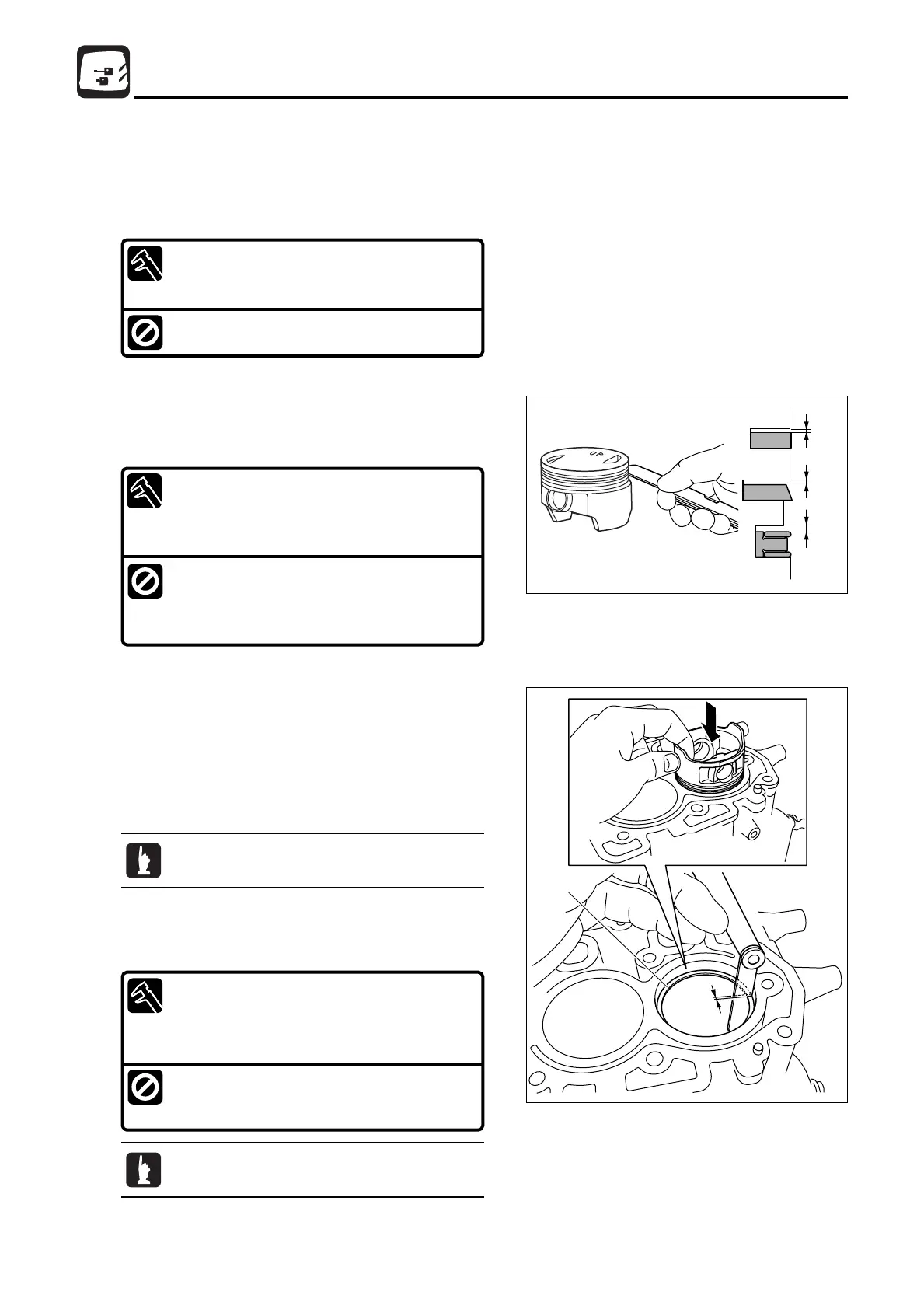

31) Inspection of Piston Rings

1 Push piston ring 1 into ring gauge 61.000mm (2.40157in)

parallel to top edge.

2. When ring gauge is not available, use piston crown to push

piston ring 1 into to cylinder.

3. Measure piston ring closed gap a. Replace if it is over

specified value.

Piston Ring Closed Gap a :

Top Ring : 0.15 - 0.30 mm (0.0059 - 0.018 in)

Second Ring : 0.35

-

0.50 mm (0.0138

-

0.0197 in)

Oil Ring : 0.20

-

0.70 mm (0.0079

-

0.0276 in)

Functional Limit :

Top Ring : 0.50 mm (0.0197 in)

Second Ring : 0.70 mm (0.0276 in)

Measure at the top or bottom of cylinder bore

with no wear.

Piston clearance = Cylinder inner diameter

(maximum) - Piston outer diameter a

0.020 - 0.055 mm (0.00079 - 0.00217 in)

Functional Limit :

0.150 mm (0.00591 in)

29) Inspection of Piston Clearance

1. Obtain piston clearance through calculation described below.

If piston clearance is over specified limit, replace cylinder

block, or piston and piston rings as a set, or both cylinder

block, piston and piston rings.

E_MFS20C_ch05_090105.qxd 09.1.20 5:25 PM ページ 44

Loading...

Loading...