43

10. CHECK AND ADJUSTMENTS

■ Grade Setting Error

• Perform the following check only after completing "■ Horizontal Rotation Grade Error" and "■ Horizontal

Rotation Cone Error".

PROCEDURE Checking

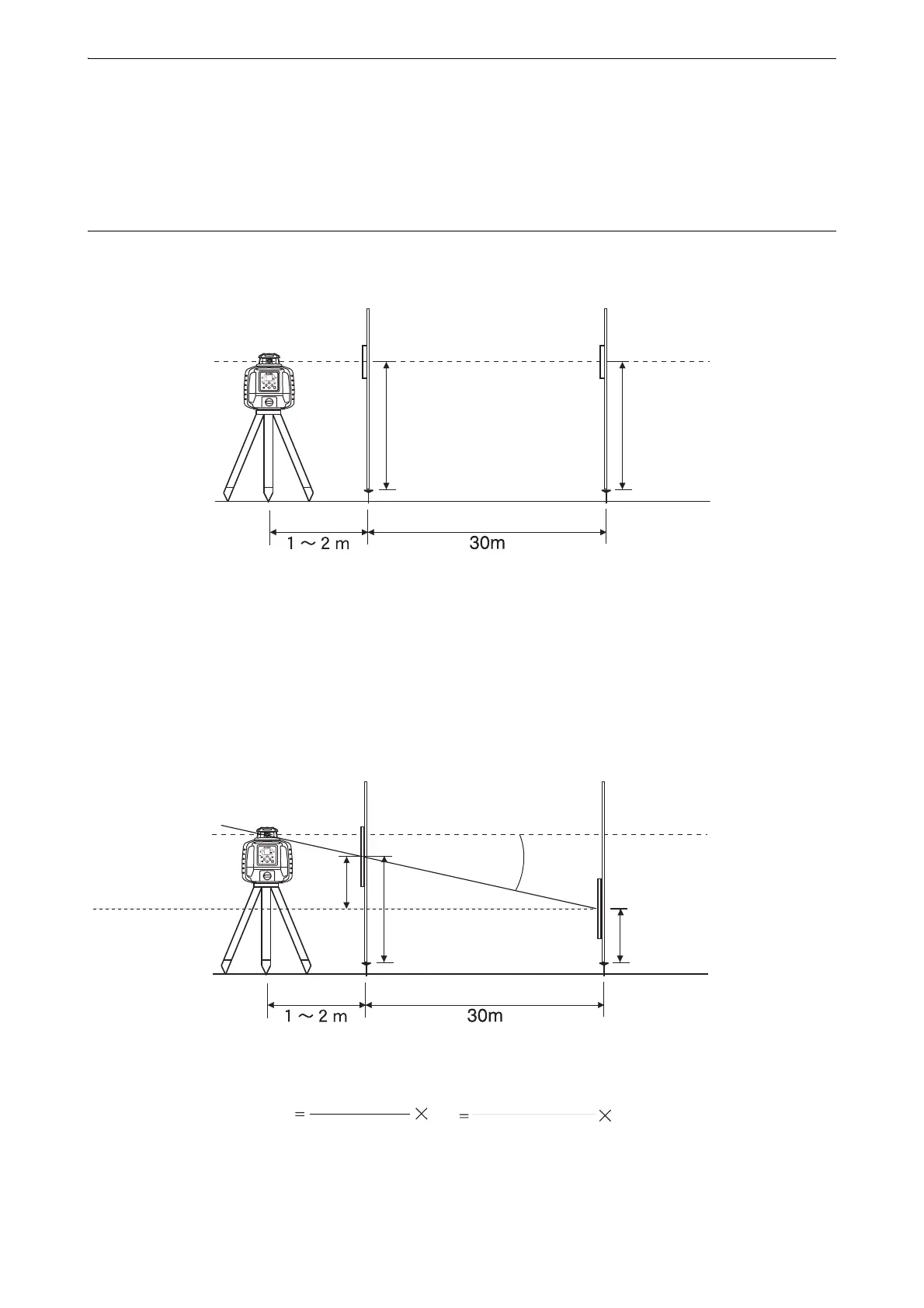

1. Setup the X- side facing the staff as shown in the figure.

Securely position Nail 1 and Nail 2 exactly 30m apart.

2. Turn on power for the RL-HV and verify the staff height of Nail 1 and

Nail 2 at grade setting of 0% with LS-80X and record.

At this time the staff height for Nail 1 and Nail 2 should recorded as

h1 and h2 (mm). Check the LS-80X is set at high7 precision.

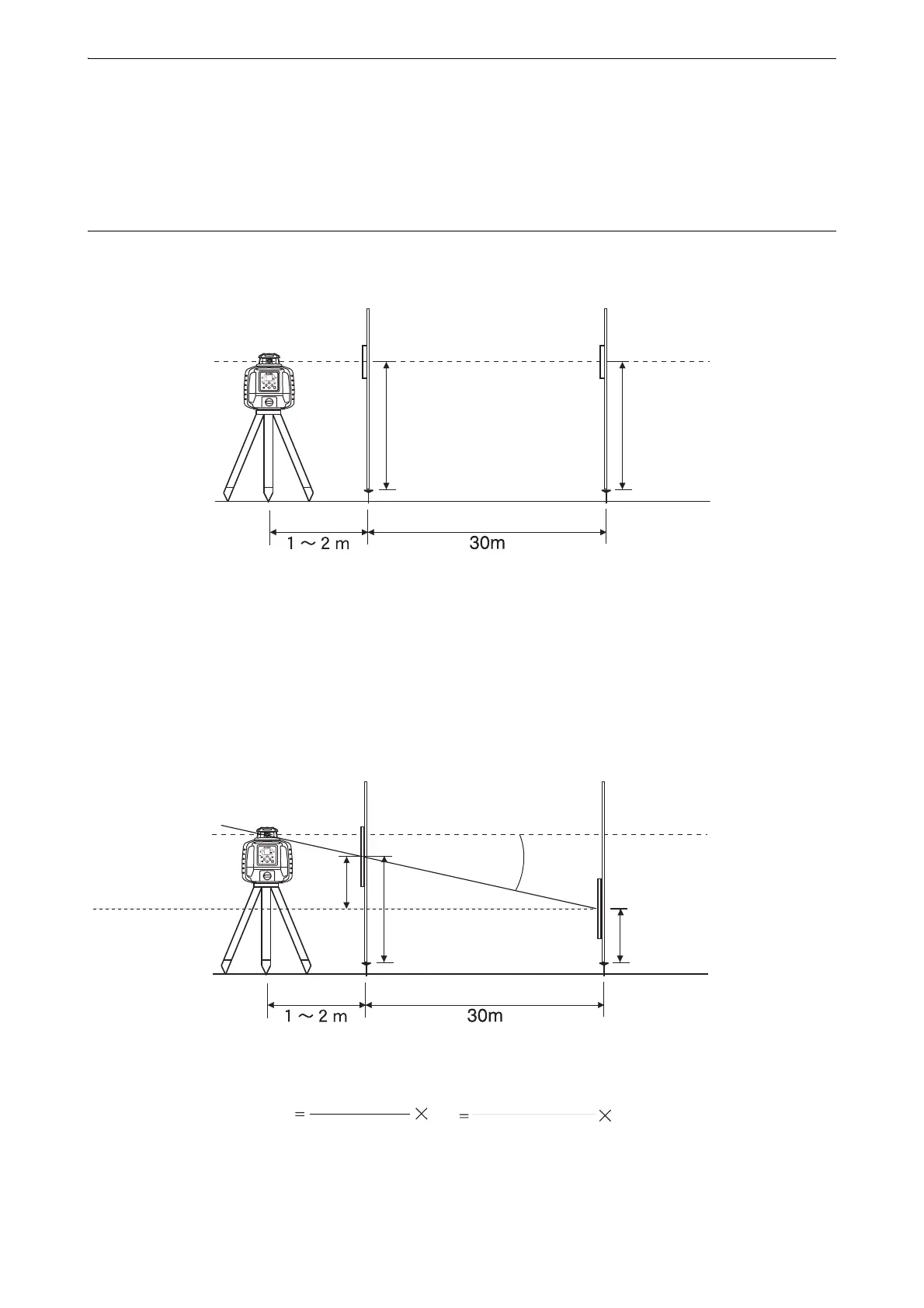

3. Set X axis grade to +1.000%.

Align read the elevation of the laser beam in millimeters at Nail 1 and

Nail 2. Designate these elevations as “h3” at Nail 1, and “h4” at Nail

2.

4. Using the elevation readings for h1, h2, h3 and h4, complete the equation below.

If the calculated result is the range of 0.990% - 1.010%, the instrument is normal.

If the calculated result for either axis is out of the range, contact your local dealer.

Repeat the procedure aligning the “Y” axis on the line created by Nail 1 and Nail 2.

h1 h2

X(%)

h

30000(mm)

100

100

30000

(h2-h4)-(h1-h3)

Loading...

Loading...