BeltMaintenance

CheckingtheCondition

andTensionoftheBelts

ServiceInterval:Every50hours

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Raisethemachineandsupportitwithjack

standswitha460kg(1,015lb)capacity.

3.Checktheauxiliarypump-drivebeltcondition

andtension(Figure56).

Note:Thebeltshoulddeect1.3cm(1/2inch)

when1.4kg(3lb)offorceisappliedtothebelt

midwaybetweentheauxiliarypumpandengine

pulleys.Ifthebelttensionistoohighortoolow,

refertoAdjustingtheAuxiliaryPump-DriveBelt

(page49).

4.Checkconditionofthetransmission-drivebelt

(Figure56).

Note:Thetransmissionbelthasan

automatic-springtensioner.

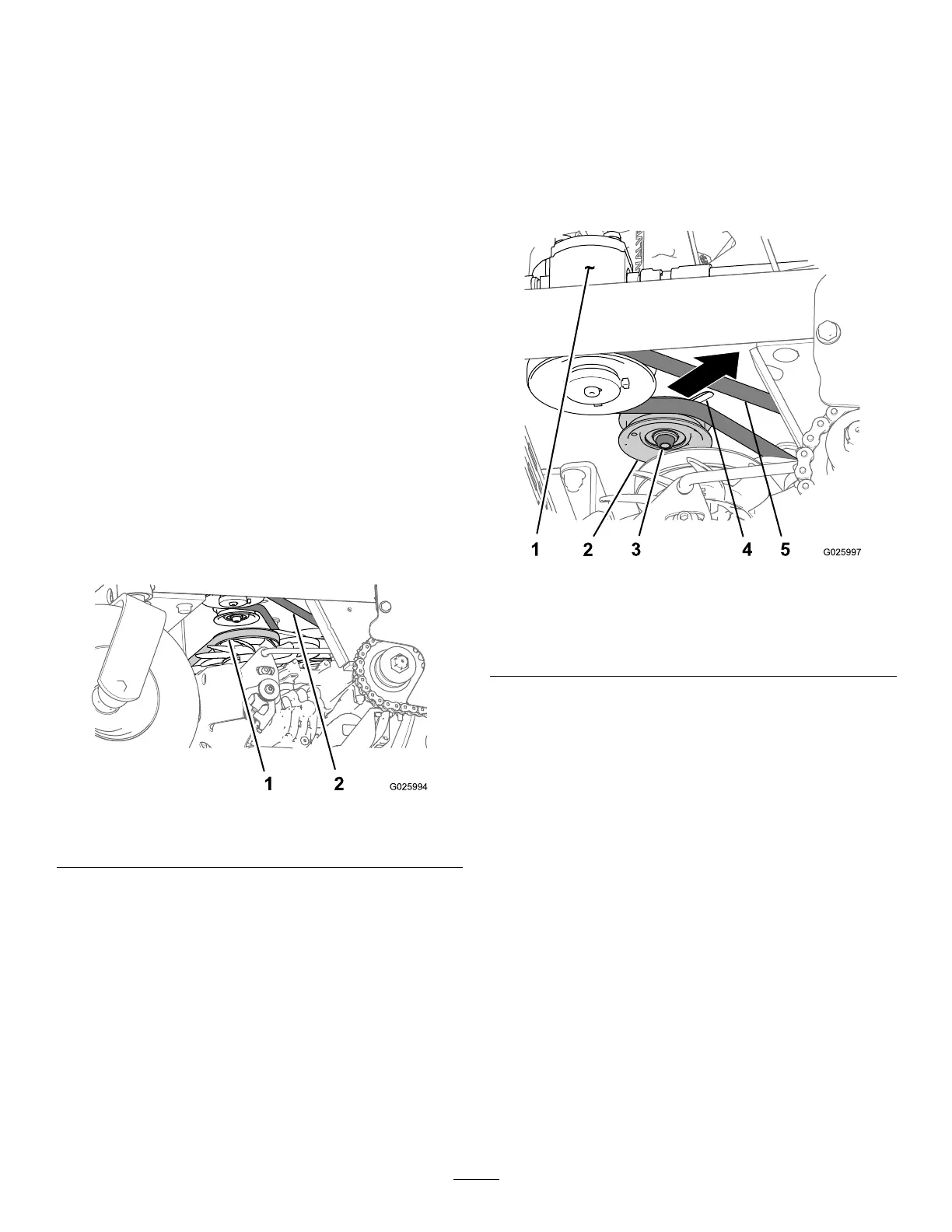

g025994

Figure56

1.Transmission-drivebelt2.Auxiliarypump-drivebelt

AdjustingtheAuxiliary

Pump-DriveBelt

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Loosenthelocknut(3/8inch)thatsecuresthe

auxiliarypump-idlerpulleytothechassisofthe

machine.

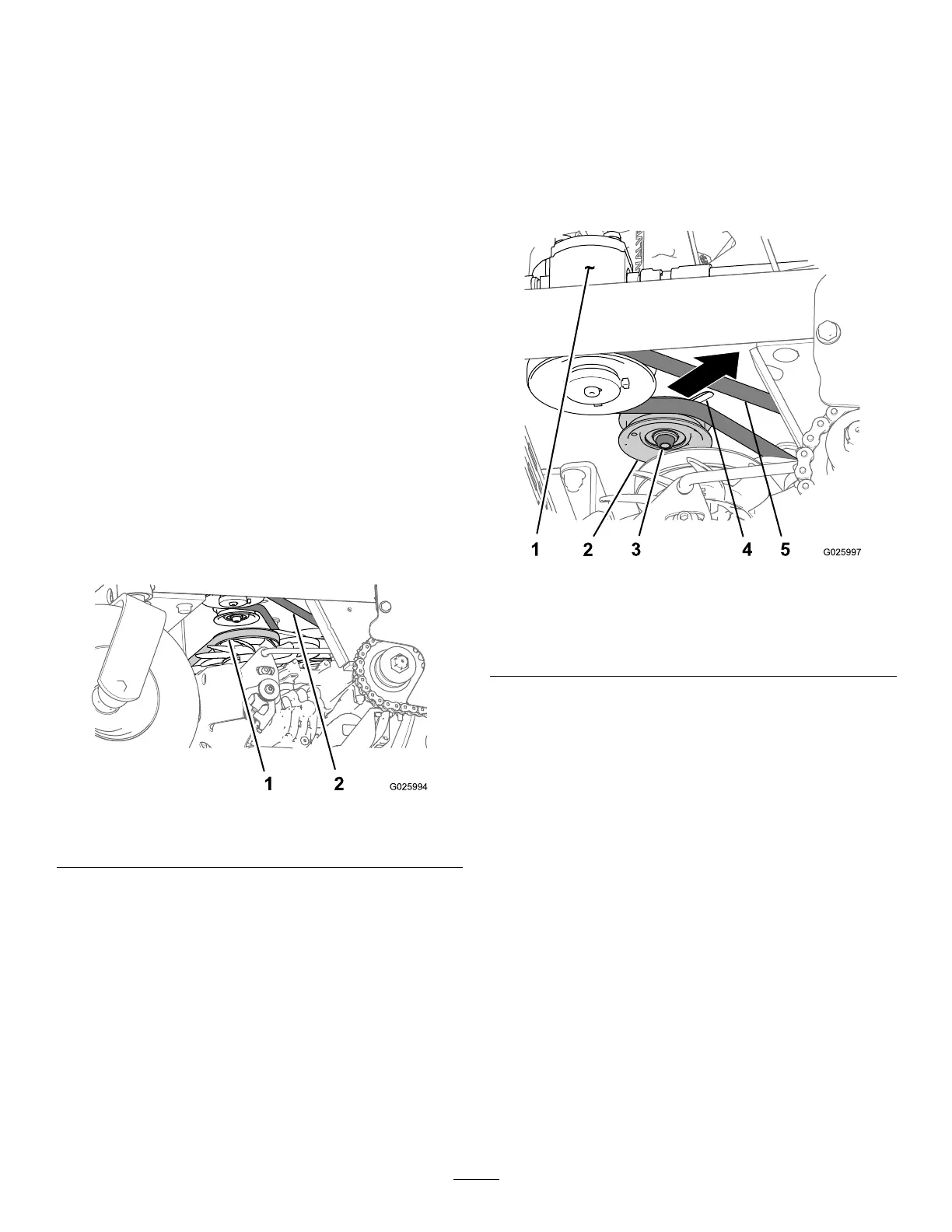

g025997

Figure57

1.Auxiliarypump

4.Adjustmentslot(chassis)

2.Auxiliarypump-idlerpulley5.Auxiliarypump-drivebelt

3.Locknut(3/8inch)

3.Adjustthebelttensionasfollows:

•Movetheauxiliarypump-idlerpulley

rearwardandoutwardtotightenthebelt.

•Movetheauxiliarypump-idlerpulleyforward

andinwardtoloosenthebelt.

Note:Thebeltshoulddeect1.3cm(1/2inch)

when1.4kg(3lb)offorceisappliedtothebelt

midwaybetweentheauxiliarypumpandengine

pulleys.

4.Tightenlocknutto37to45N∙m(27to33ft-lb).

Replacingthe

Transmission-DriveBelt

Note:Noadjustmentsarerequiredforbelttension.

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Insertabreakerbarintothesocketofthe

belt-tensionbracketandmovethebracket

outwardandforward(Figure58).

49

Loading...

Loading...