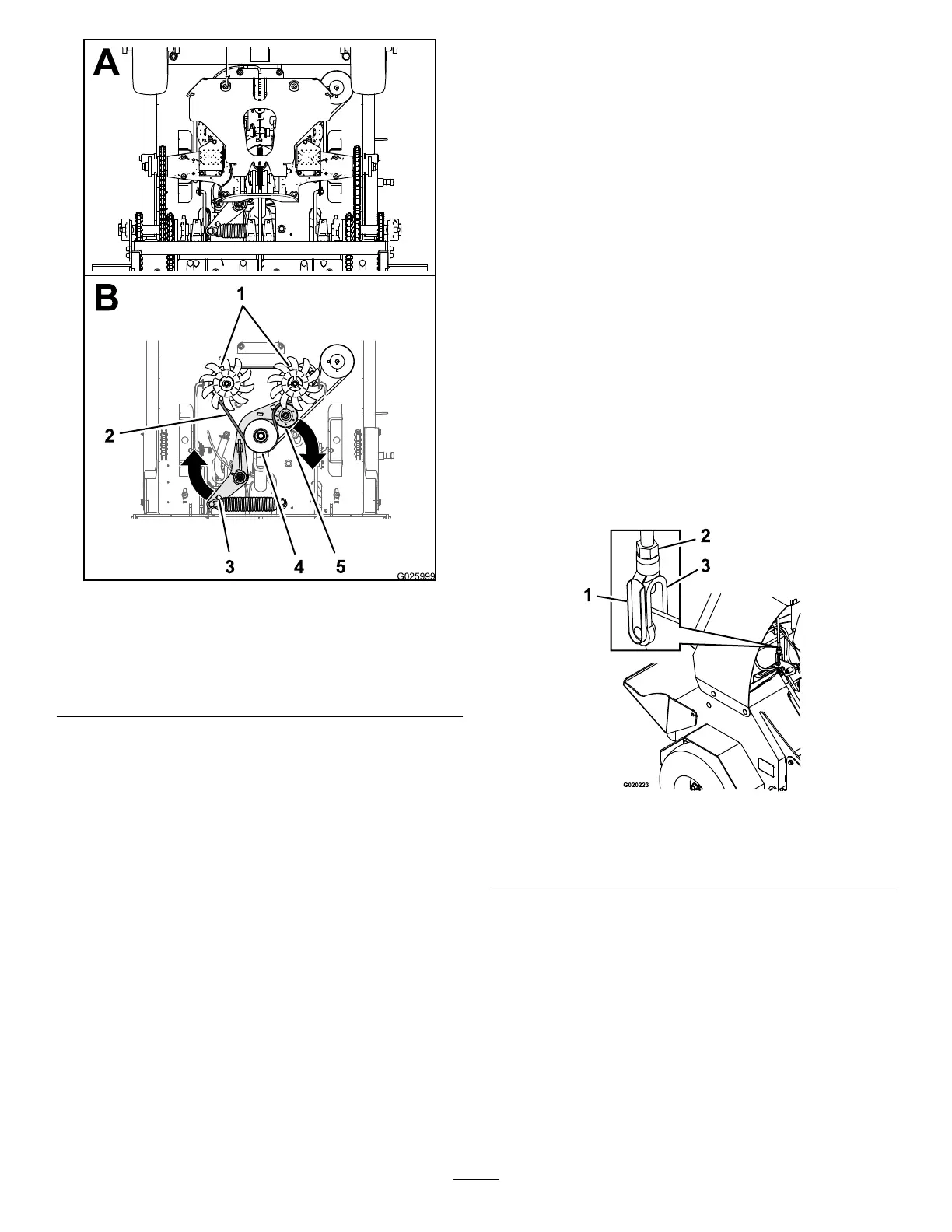

g025999

Figure58

1.Transmissionpulley4.Enginepulley

2.Transmission5.Tensionerpulley

3.Socket(belt-tension

bracket)

3.Slipthetransmission-drivebeltoftheengine,

tensioner,andtransmissionpulleys(Figure58).

4.Routethenewtransmission-drivebeltaround

theengine,tensioner,andtransmissionpulleys

asshowninFigure58

5.Releasethebelt-tensionbracketandallowthe

springtotensionthebelt(Figure58).

Note:Makesurethatthebelt-tensionbracket

andpulleycanmovefreely.

ControlsSystem

Maintenance

Adjustingthe

Traction-ControlLinkage

1.Parkthemachineonalevelsurface.

2.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Pushthecontrolleverallthewayforwardtoward

thefrontreferencebar.

4.Ifthecontrollevercontactsthereference

barorIfthegapbetweenthecontrolleverand

referencebarislargerthan1.6mm(1/16inch),

performthefollowing:

A.Releasethecontrolleverandallowitto

returntotheneutralposition.

B.Removethespring-clevispinfromthefork

ttingofthetraction-controllinkage(Figure

59).

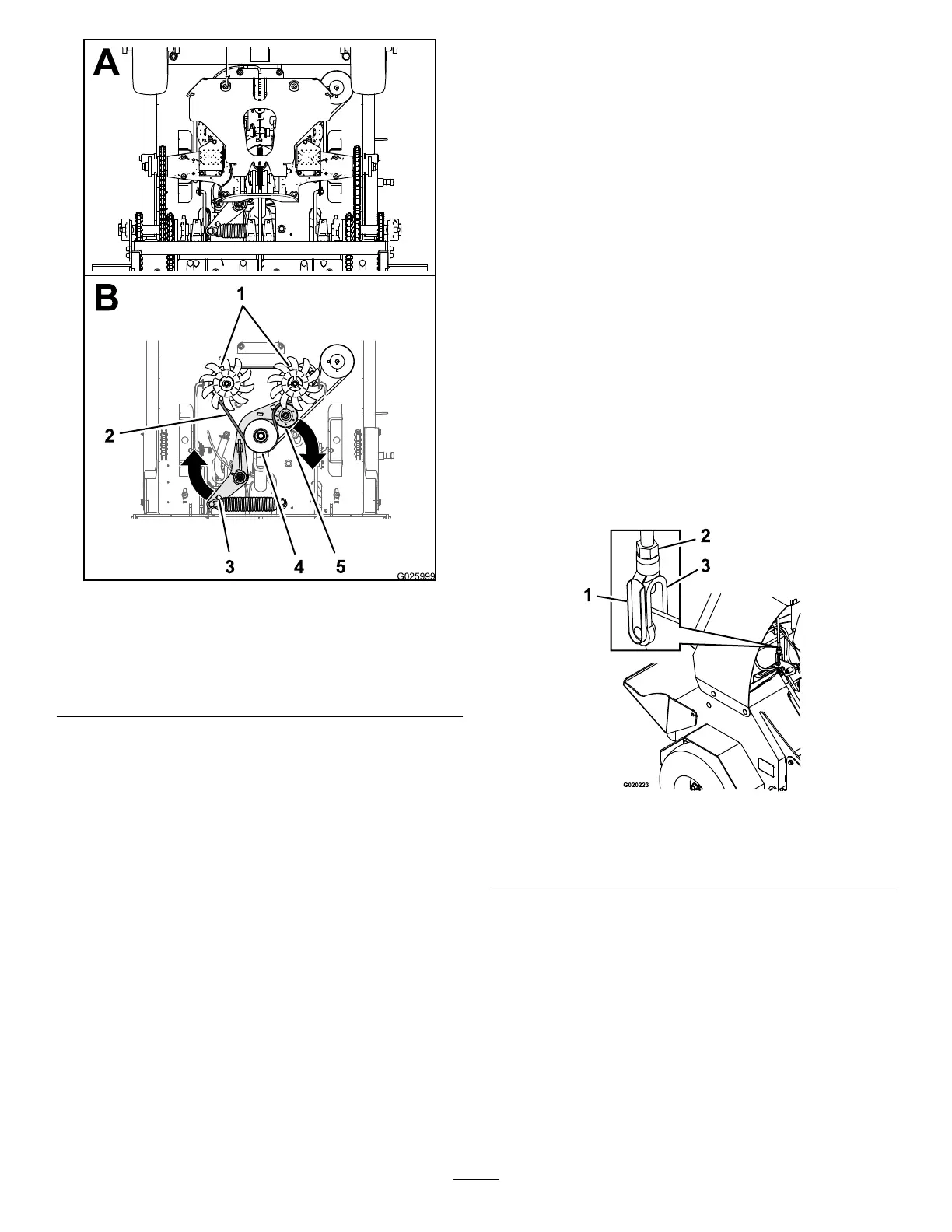

g020223

Figure59

1.Spring-clevispin

3.Turnbuckle

2.Locknut

C.Adjusttheforkttingtosettheinitialgap

asfollows:

•Ifthecontrollevercontactsthe

referencebar,rotatetheforktting

(Figure59)counterclockwise(asviewed

fromthetopofthemachine).

•Ifthegapbetweenthecontrolleverand

referencebarislargerthan1.6mm

(1/16inch),rotatetheforktting(Figure

59)counterclockwise.

D.Installthespringclevispin(Figure59)and

movethecontrolleverforward.

50

Loading...

Loading...