E.RepeatstepsAthroughDuntilthereis

agapapproximately1.6mm(1/16inch)

betweenthecontrolleverandthefront

referencebar.

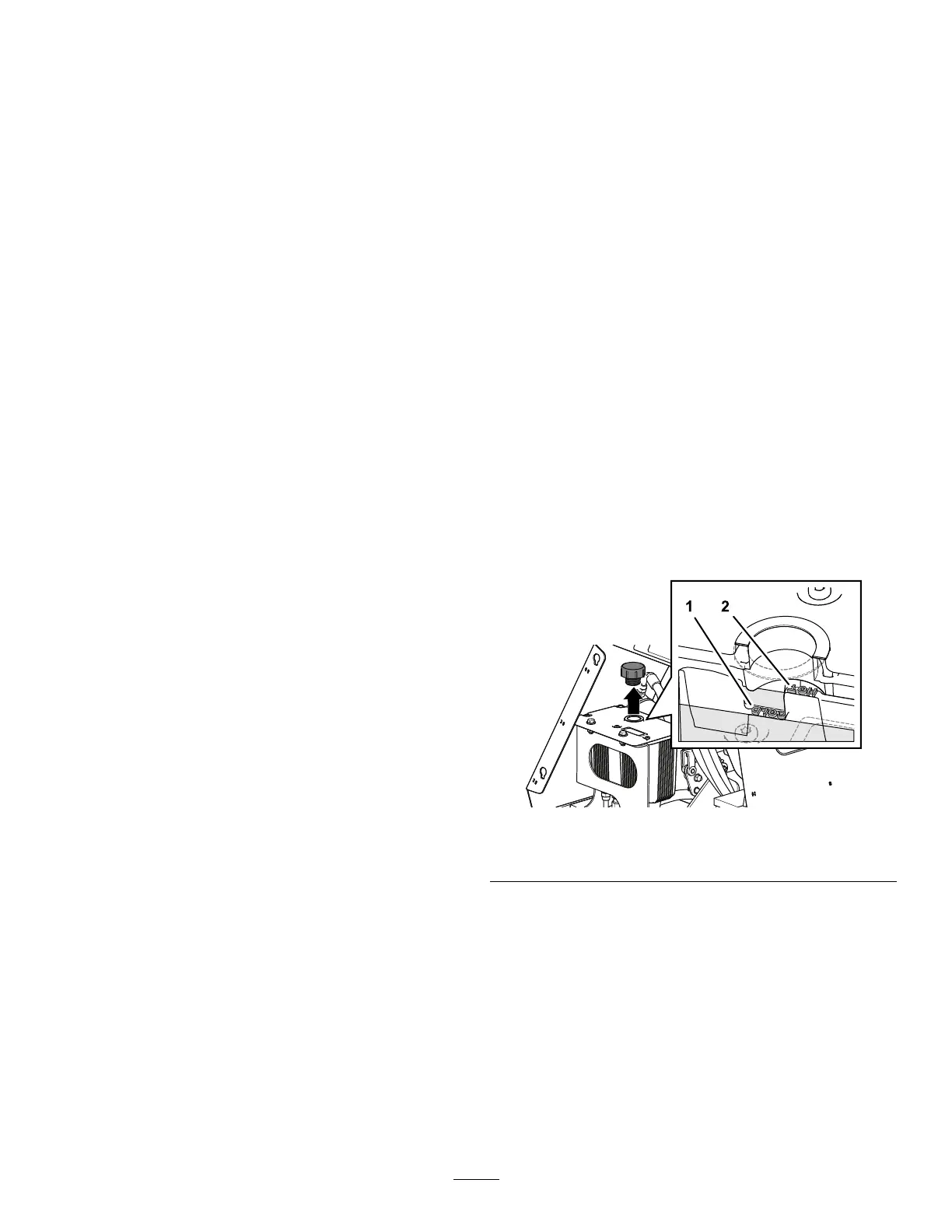

F.Removethespring-clevispin,rotatethe

turnbuckleclockwise1additionalturn,and

insertthespring-clevispin(Figure59).

5.Repeatsteps4Athrough4Ffortheother

traction-controllinkage.

HydraulicSystem

Maintenance

MaintainingtheAuxiliary

HydraulicSystem

HydraulicFluidSpecication

AW-32hydraulicuid

CheckingtheAuxiliary

Hydraulic-FluidLevel

ServiceInterval:Every50hours

1.Parkthemachineonalevelsurface.

2.Lowerthetinestotheground.

3.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

4.Removetheconsolepad;refertoRemovingthe

ConsolePad(page32).

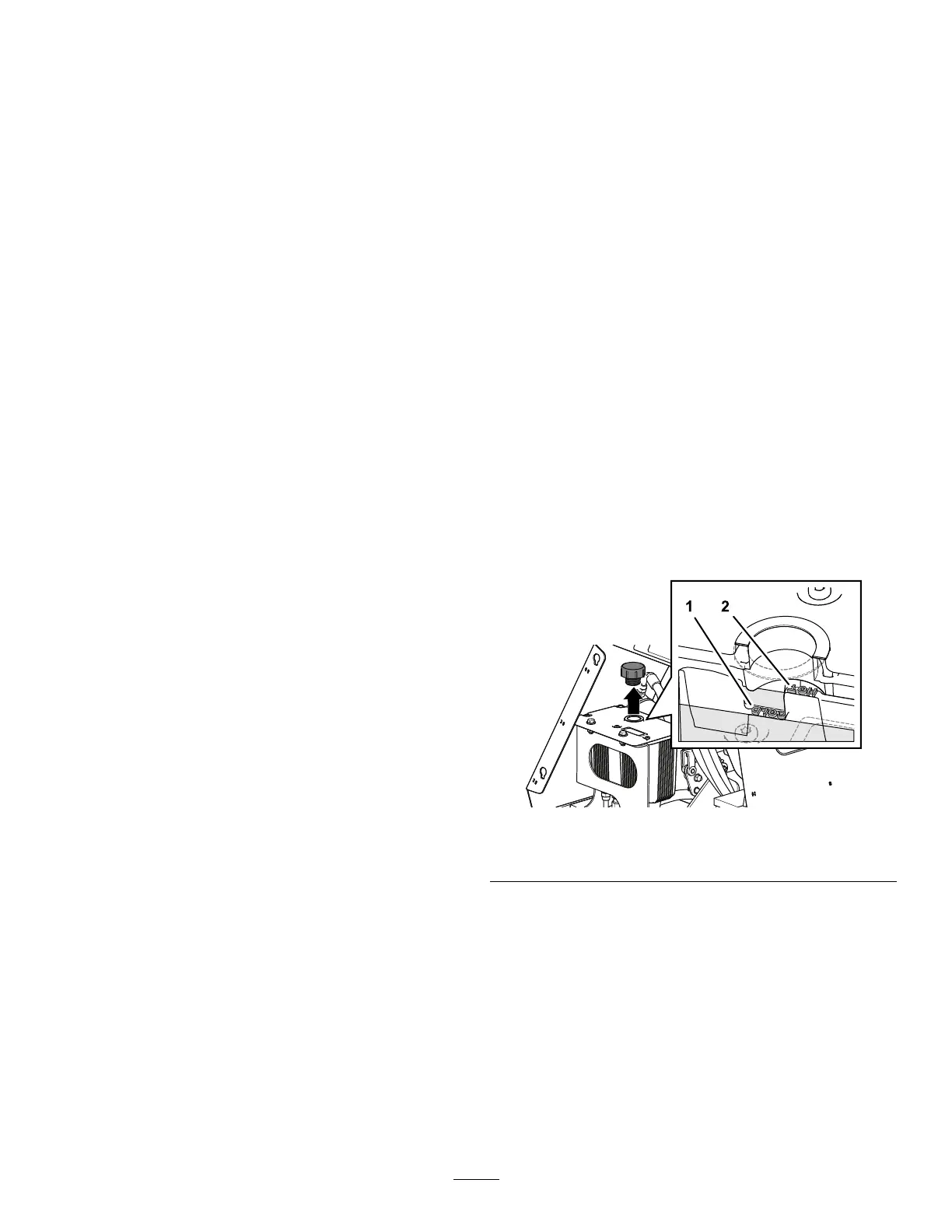

5.Cleantheareaaroundthehydraulicreservoir

cap(Figure60).

g314129

Figure60

1.Colduidlevel2.Hotuidlevel

6.Removethecapandcheckhydraulic-uidlevel

inthereservoir(Figure60).

Note:Thehydraulic-uidlevelshouldcoverthe

wordColdthatisembossedintothebafeof

thereservoir.

7.Ifnecessary,addthespeciedhydraulicuidto

thereservoiruntiltheuidcoverstheColduid

levelonthebafe(Figure60).

Note:ThebafeionthereservoirislabeledHot

andCold.Fillthereservoirtotheappropriate

leveldependinguponthetemperatureofthe

uid.Theuidlevelvarieswiththetemperature

51

Loading...

Loading...