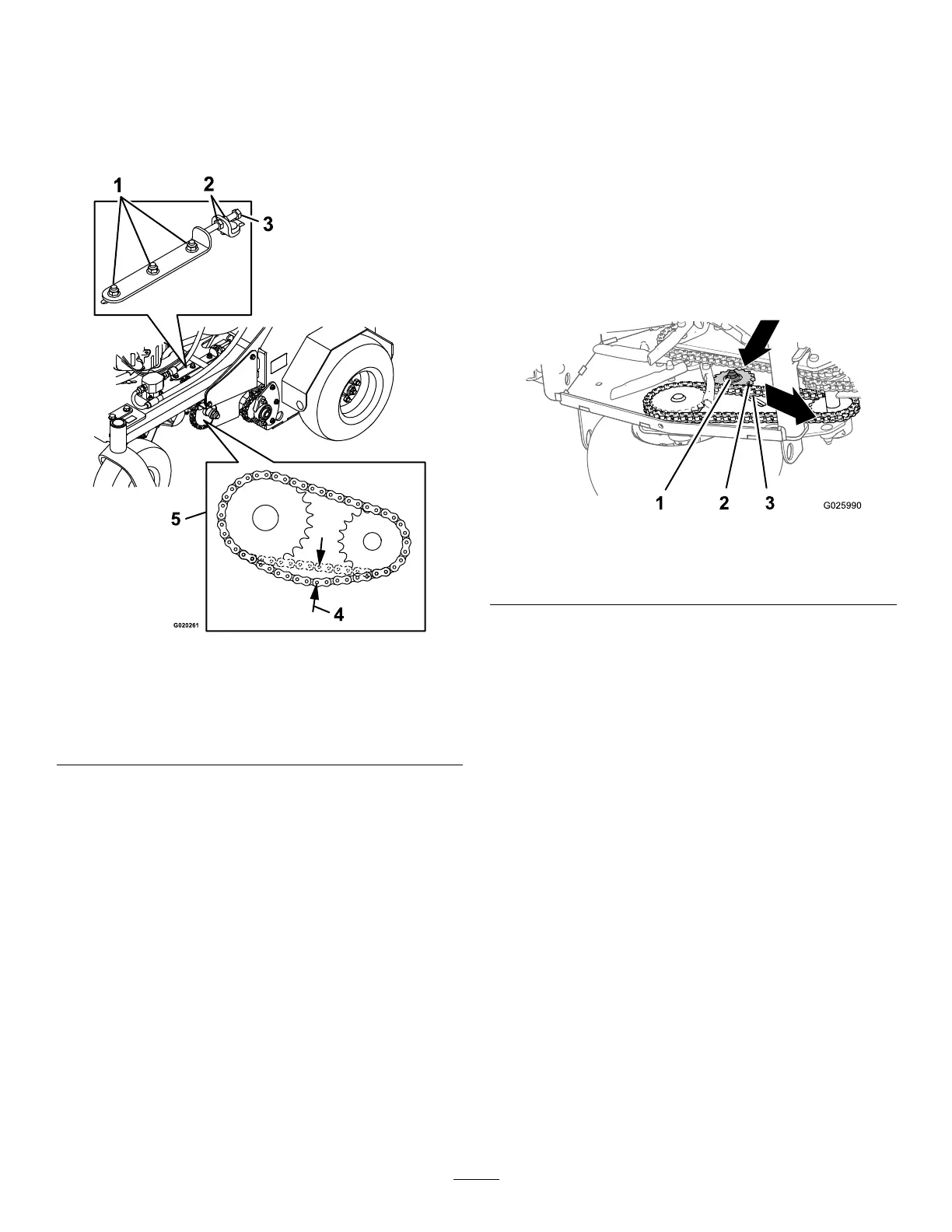

andtensionerplate,andthe2nutssecuringthe

adjustmentboltatthetensionerplateasshown

inFigure71.

Note:Youmustloosenthenutsandboltsthat

securethetransmissionmountandtensioner

plateatbothsidesofthemachine.

g020261

Figure71

1.Hydromountingboltsand

nuts

4.6to12mm(1/4-1/2inch)

2.Nuts

5.Guardremovedforclarity

3.Adjustmentbolt

5.Turntheadjustmentbolttomovetransmission

adjustmentplatesandtransmission.

6.Whenthechainscanmoveupanddown6to12

mm(1/4to1/2inch),tightenthenutsonboth

sidesoftheadjustmentbolts.

7.Tightennutsandboltsthatsecurethehydro

mounting.

8.Adjustthetraction-controllinkage,referto

AdjustingtheTraction-ControlLinkage(page

50).

AdjustingtheDriveWheel

ChainTension

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Lifttherearofthemachineandsupportitusing

jackstands.

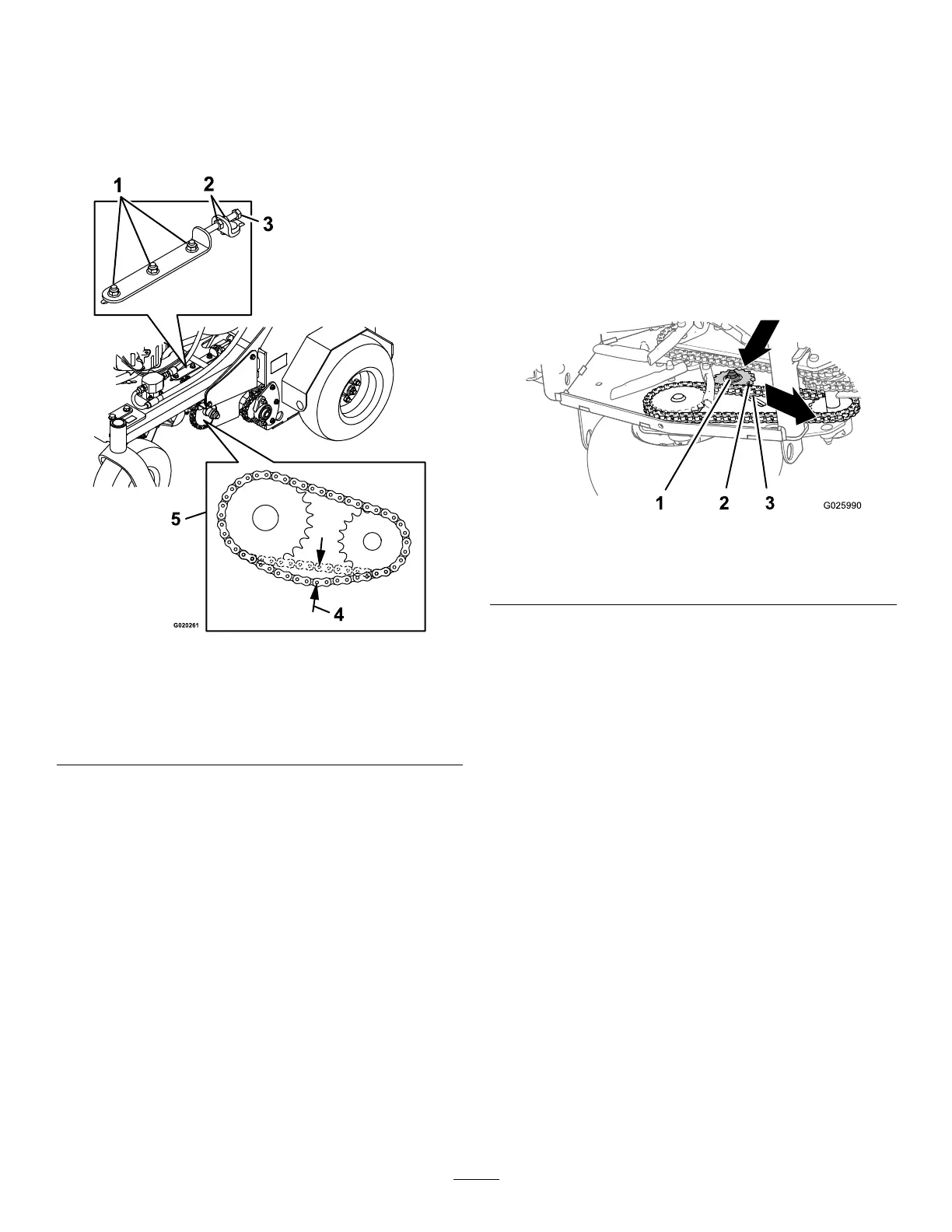

3.Checkthetensionofthedrive-wheelchains

(Figure72).

Note:Thechainsshouldmoveupanddown6

to12mm(1/4to1/2inch).

g025990

Figure72

1.Locknut3.Drive-wheelchain

2.Idlersprocket

4.Loosenthelocknutandcarriageboltthatsecure

theidlersprocket(Figure72).

5.Increaseordecreasechaintensionby

performingthefollowing:

•Pushdownandforwardonthesprocket

toincreasethechaintensionasshownin

Figure72.

•Liftupandbackonthesprockettodecrease

thechaintension.

6.T orquethelocknutto91to113N∙m(67to83

ft-lb).

7.Checkthechaintensionandifnecessaryrepeat

steps4through6untilyoucanmovethechain

upanddown6to12mm(1/4to1/2inch).

57

Loading...

Loading...