oftheuid.TheColdlevelshowsthelevelof

theuidwhenitisat24°C(75°F).TheHot

levelshowsthelevelofuidwhenitisat107°C

(225°F).

Forexample:Iftheuidisatambient-air

temperature,about24°C(75°F),llonlytothe

Coldlevel.Iftheuidisabout65°C(150°F),ll

tohalfwaybetweentheHotandColdlevels.

8.Replacethehydraulicreservoircapandtighten

ituntilitissnug(Figure60).

Note:Donotovertightenthereservoircap.

9.Installtheconsolepad;refertoRemovingthe

ConsolePad(page32).

ChangingtheAuxiliaryHydraulic

ReservoirFluidandFilter

ServiceInterval:Aftertherst100hours

Every250hoursthereafter

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Carefullycleanareaaroundthefrontofthe

auxiliarypump,llcapforthereservoir,andlter

(Figure61).

Important:Ensurethatnodirtor

contaminationentershydraulicsystem.

g026008

Figure61

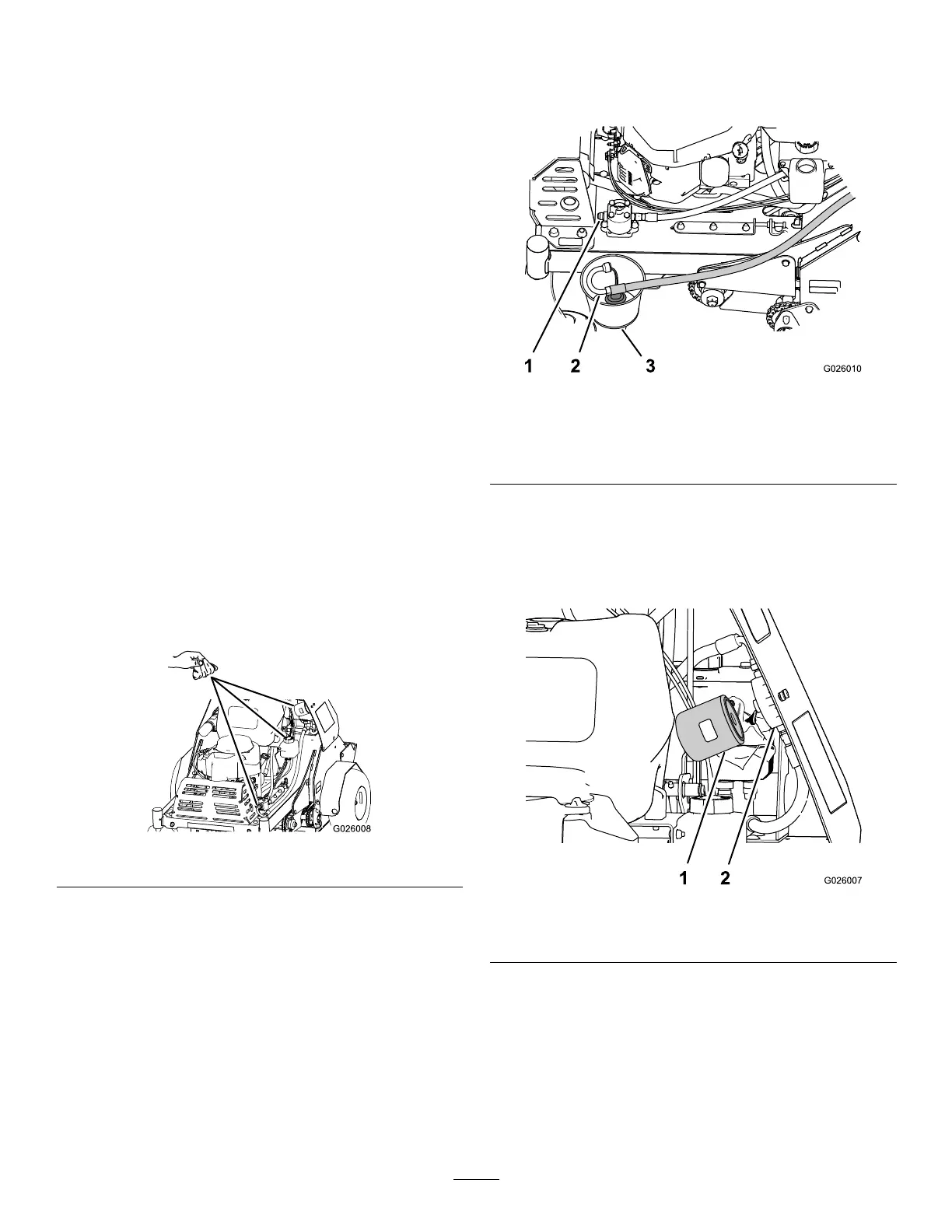

3.Atthefrontoftheauxiliaryhydraulicpump,

removetheinlethosefromthehydraulictting

inthepump,placetheendofthehoseinadrain

container,andallowtheuidtodrain(Figure62).

g026010

Figure62

1.Hydraulictting(auxiliary

hydraulicpump)

3.Draincontainer

2.Inlethose

4.Cleanaroundthettingforthehydraulicpump.

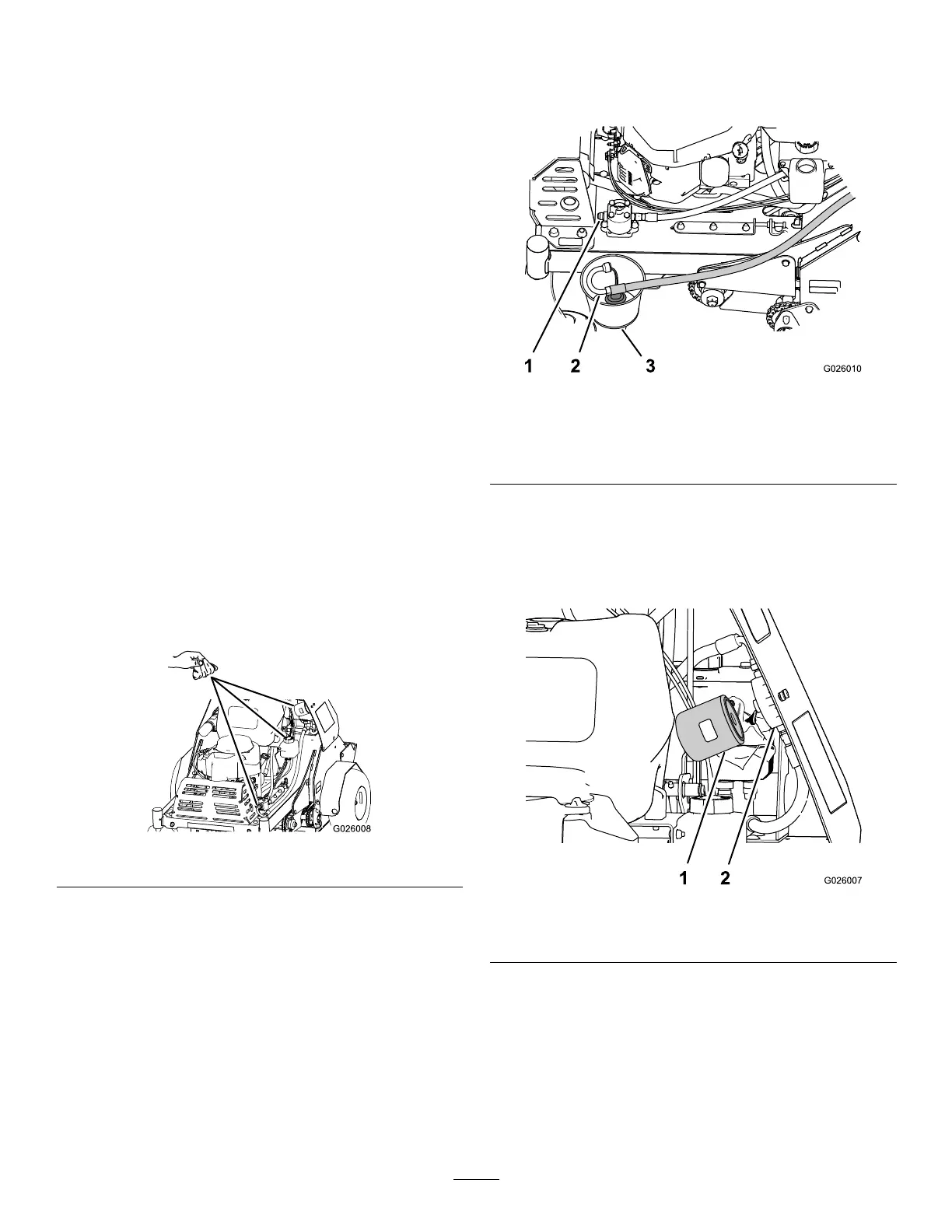

5.Rotatetheauxiliaryhydrauliclter

counterclockwiseandremoveitfromthe

baseofthelteradapter(Figure63).Allowthe

uidtodrain.

g026007

Figure63

1.Auxiliaryhydrauliclter

2.Filteradapter

6.Applyathincoatofspecieduidontotheseal

ofthenewhydrauliclter.

7.Installthelterbyrotatingitclockwiseontothe

lteradapteruntilthesealcontactsthelter

adapter,thentightenthelteranadditional2/3

to3/4turn(Figure63).

8.Installtheinlethoseontothettinginthepump

andtorquethehosettingto50N∙m(37ft-lb).

52

Loading...

Loading...