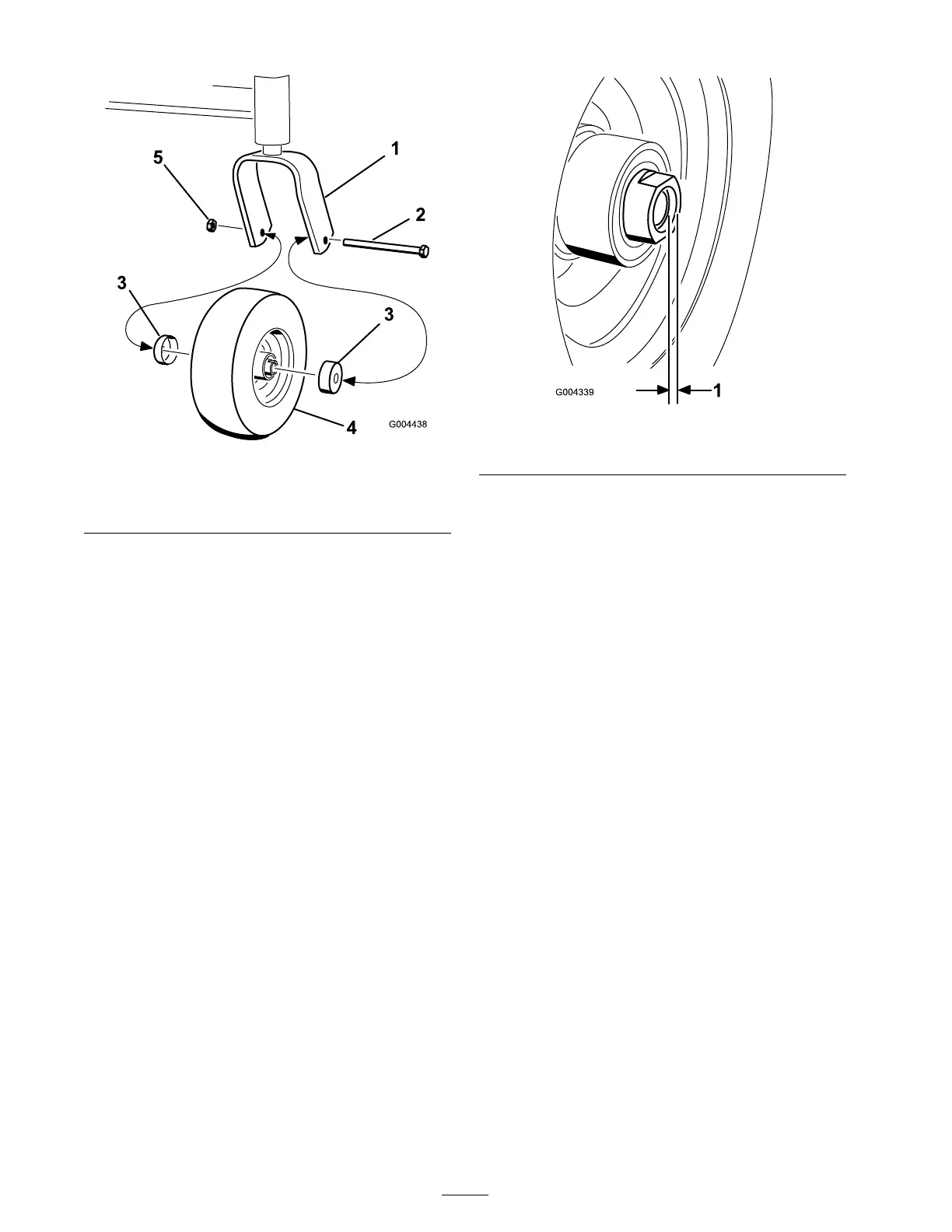

Figure 28

1. Caster fork 4. Caster wheel

2. Bolt

5. Nut

3. Seal guard

6. R emo v e one of the spacer n uts (with wrenc h

flats) from the axle ( Figure 30 ).

Note: T hread loc king adhesi v e has been

applied to the spacer n uts .

7. R emo v e the axle without remo ving the

opposite spacer n ut ( Figure 30 ).

8. R emo v e the seals and inspect the bearings

for w ear or damag e . R e place the bearings if

needed.

9. P ac k the bearings with g eneral pur pose g rease .

10. Inser t the bearing and a new seal into the

wheel ( Figure 30 ).

Note: Do not install the n ut all the w a y onto

the axle .

11. If both spacer n uts w ere remo v ed from the

axle , apply thread loc king adhesi v e to the

spacer n ut. Install the spacer n uts onto the axle

lea ving an 1/8 inc h (3mm) of the n ut past the

axle ( Figure 29 ).

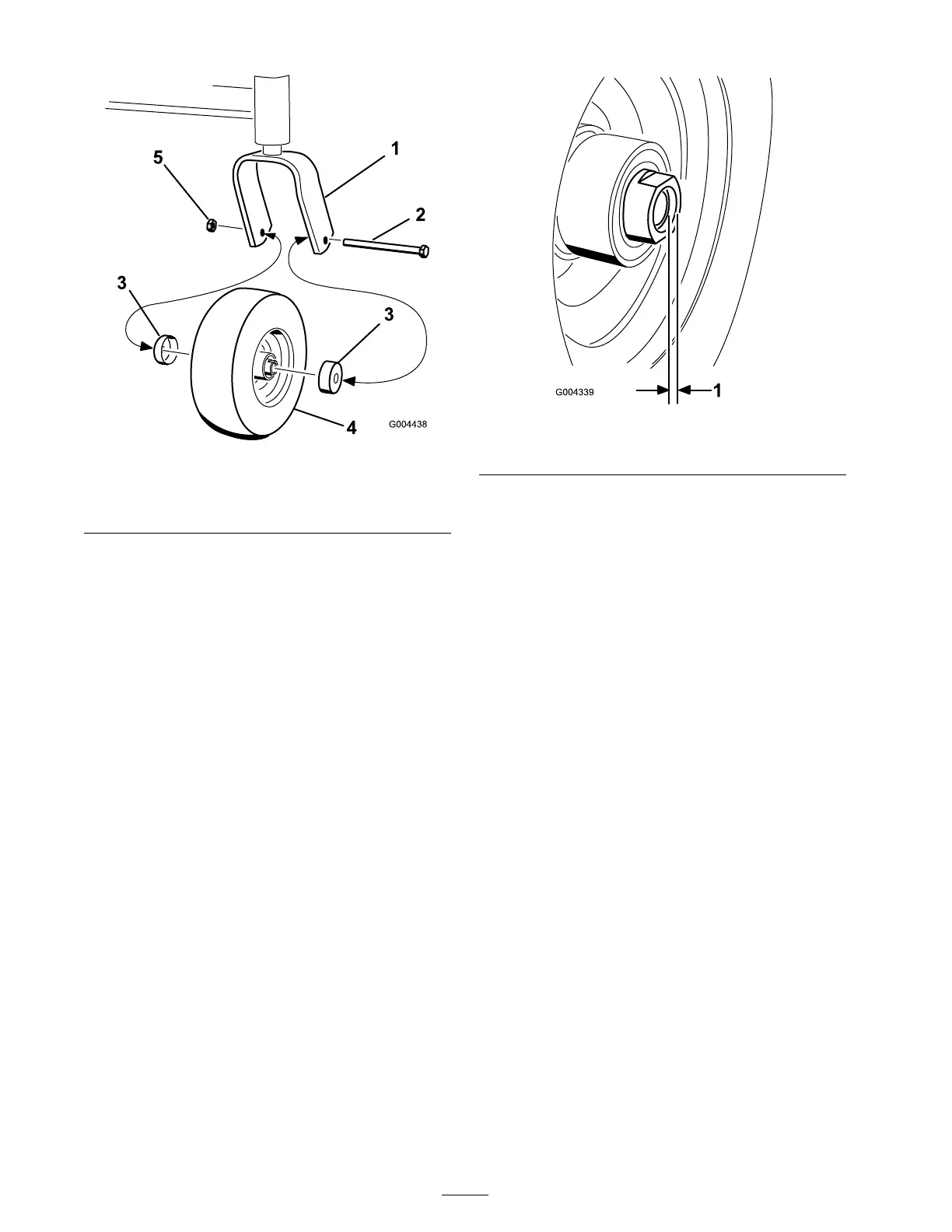

Figure 29

1. 1/8 inch (3 mm) of the nut past the axle

12. Install the assembled n ut and axle into the

wheel on the side with the bearing and a new

seal ( Figure 30 ).

13. Place the wheel with the open end facing

up and fill the area inside the wheel with

m ulti-pur pose g rease .

14. Install the second bearing and a new seal into

the wheel ( Figure 30 ).

15. Apply thread loc king adhesi v e to the second

spacer n ut and install it onto the axle with the

wrenc h flats facing outw ard.

16. T or que the spacer n ut to 75-80 in-lb (8-9 N ⋅ m)

then loosen it and tor que it to 20–25 in-lb (2-3

N ⋅ m). Mak e sure the axle does not extend past

either n ut ( Figure 29 ).

17. Install the seal guards o v er the wheel hubs and

inser t the wheel into the caster fork ( Figure 28 ).

18. Install the caster bolt and tighten the n ut

( Figure 28 ).

Important: Check the bearing

adjustment often to pr ev ent seal and

bearing dama ge. Spin the caster tir e. T he

tir e should not spin fr eel y mor e than 1 to 2

r ev olutions or ha v e an y side-to-side play

betw een the caster f or k. If the wheel spins

fr eel y , adjust the torque on the spacer n ut

until ther e is a slight amount of dra g .

28

Loading...

Loading...