6. Mak e sure the speed control lev er is in the

neutral position and the tires do not rotate .

7. R e peat the linkag e adjustments if needed to

obtain neutral position.

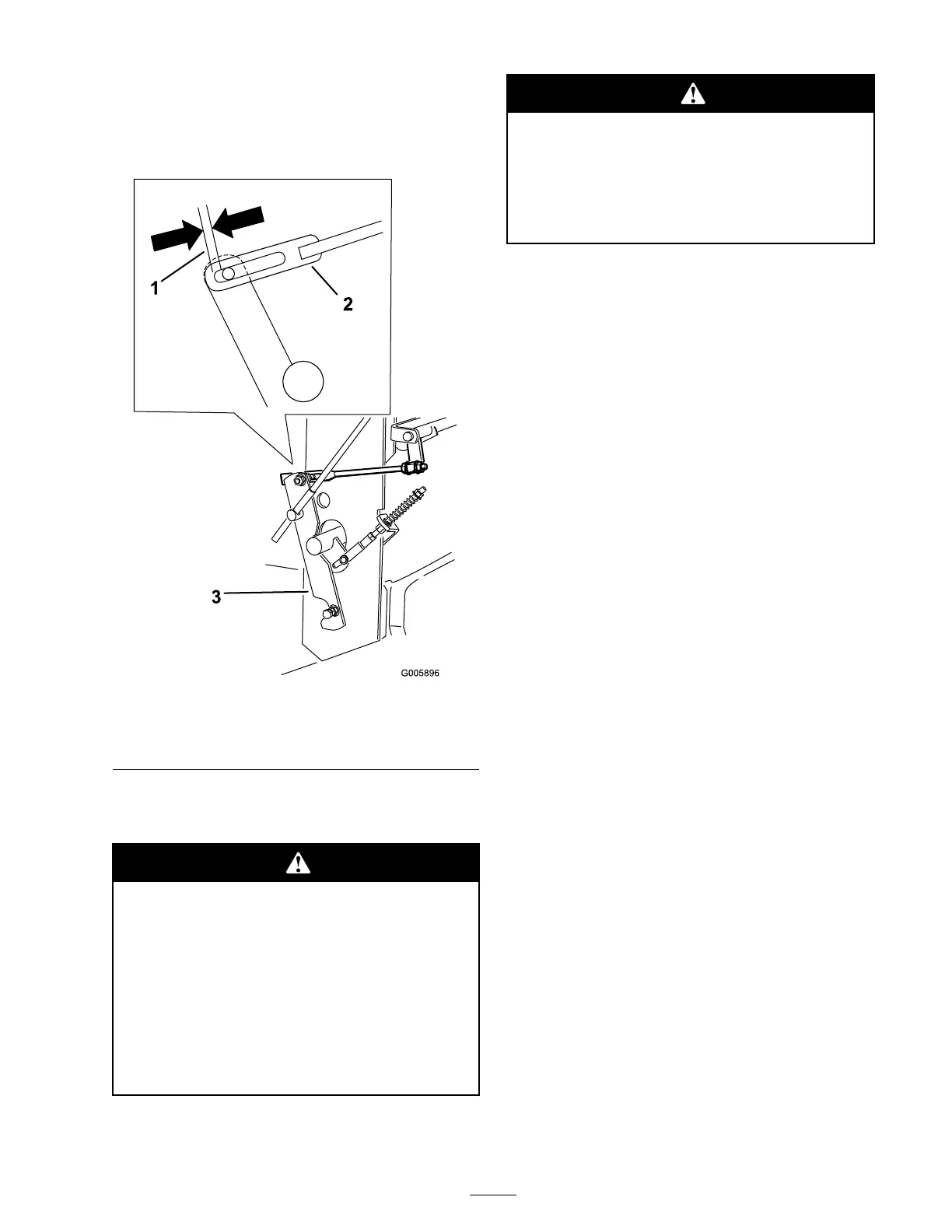

Figure 51

1. Gap needs to be equal on

left and right side

3. Control arm

2. Hydro control linkage

Adjusting the Neutral Stud

Electrical system will not perf or m pr oper

safety shut of f with Operator Pr esence

Contr ol (OPC) lev er s held in place.

• Mak e sur e Operator Pr esence Contr ol

(OPC) lev er s ar e w or king when

adjustment is completed.

• Nev er operate this unit with Operator

Pr esence Contr ol (OPC) lev er s held in

place.

Mechanical or h y draulic jacks may f ail to

suppor t machine and cause a serious injur y .

• Use jack stands when suppor ting

machine.

• Do not use h y draulic jacks.

1. With the mac hine on jac k stands , place the

speed control lev er in the neutral position.

2. Hold the OPC lev ers do wn.

Note: T he OPC lev ers m ust be held do wn

whenev er the speed control lev er is out of the

neutral position or the engine will kill.

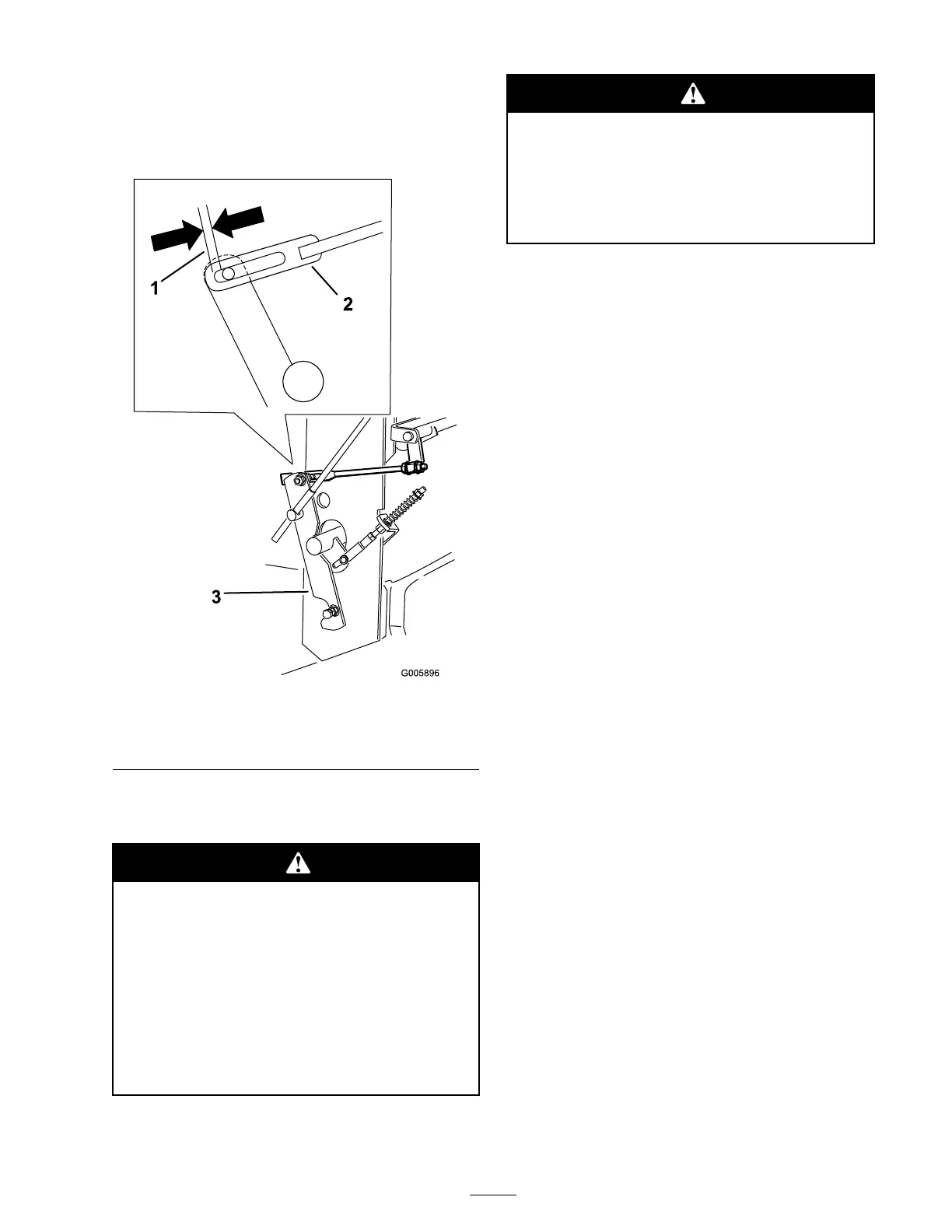

3. Adjust the left and right neutral stud until the

clevis pin in the y ok e touc hes the bac k end of

the slot in the control ar m ( Figure 52 ).

4. Mo v e the speed control lev er to the full

forw ard position.

5. Squeeze one dri v e lev er until an increased

resistance is felt. T his is neutral position. T his

is where the clevis pin in the y ok e comes to the

bac k end of the slot in the control ar m brac k et.

Note: Mak e sure y ou ha v e not reac hed the

end of the neutral loc k slot. If y ou ha v e ,

shor ten the control lev er linkag e . R efer to

Adjusting the Control R od.

6. If the wheel tur ns while holding the dri v e lev er

in neutral, the neutral stud needs to be adjusted

( Figure 52 ). If wheel stops then g o to .

7. Loosen the n ut ag ainst the y ok e ( Figure 52 ).

8. Adjust the adjustment stud until the respecti v e

dri v e wheel stops while holding the dri v e in

the neutral position (increased resistance)

( Figure 52 ).

9. T ur n the adjusting bolt appro ximately 1/4

tur n cloc kwise if the wheel is tur ning in

rev erse or tur n the bolt appro ximately 1/4

tur n counter -cloc kwise if the wheel is tur ning

forw ard ( Figure 52 ).

10. R elease the dri v e lev er to the forw ard dri v e

position and squeeze bac k into the neutral

position. Chec k to see if the wheel stops . If

not, re peat the abo v e adjustment procedure .

11. After adjustments are made , tighten the n uts

ag ainst the y ok es .

12. R e peat this procedure for the opposite side .

41

Loading...

Loading...