A blade that is bent or dama ged could

br eak apar t and could seriousl y injur e or

kill y ou or bystander s.

• Al w ays r eplace bent or dama ged

blade with a new blade.

• Nev er file or cr eate shar p notches in

the edges or surf aces of blade.

Removing the Blades

Blades m ust be re placed if a solid object is hit,

if the blade is out of balance or is bent. T o

ensure optim um perfor mance and contin ued

safety confor mance of the mac hine , use g en uine

T oro re placement blades . R e placement blades

made b y other man ufacturers ma y result in

non-confor mance with safety standards .

1. Hold the blade end using a rag or

thic kly-padded glo v e .

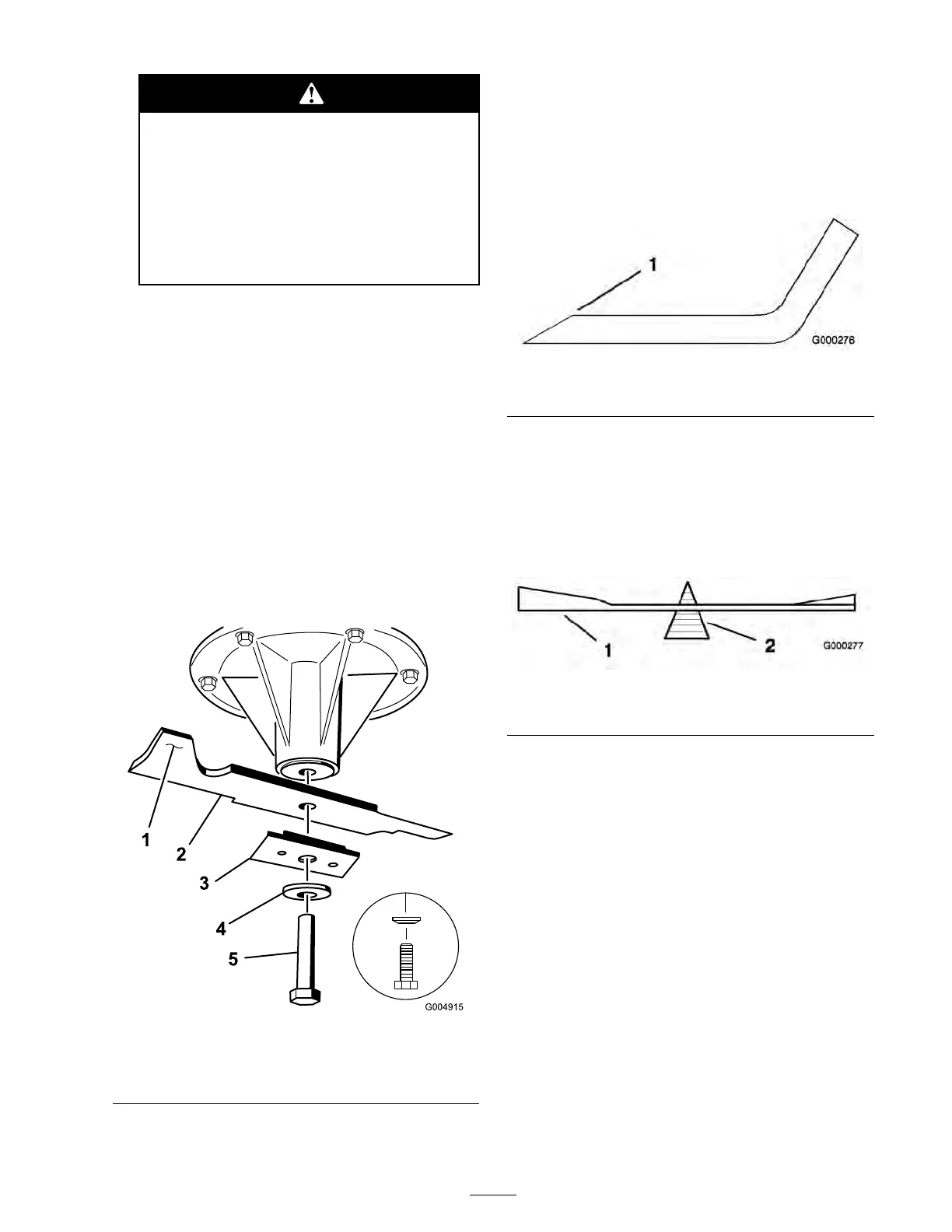

2. R emo v e the blade bolt, cur v ed w asher , blade

stiffener , and blade from the spindle shaft

( Figure 69 ).

Figure 69

1. Sail Area of Blade 4. Curved washer

2. Blade 5. Blade Bolt

3. Blade stiffener

Sharpening the Blades

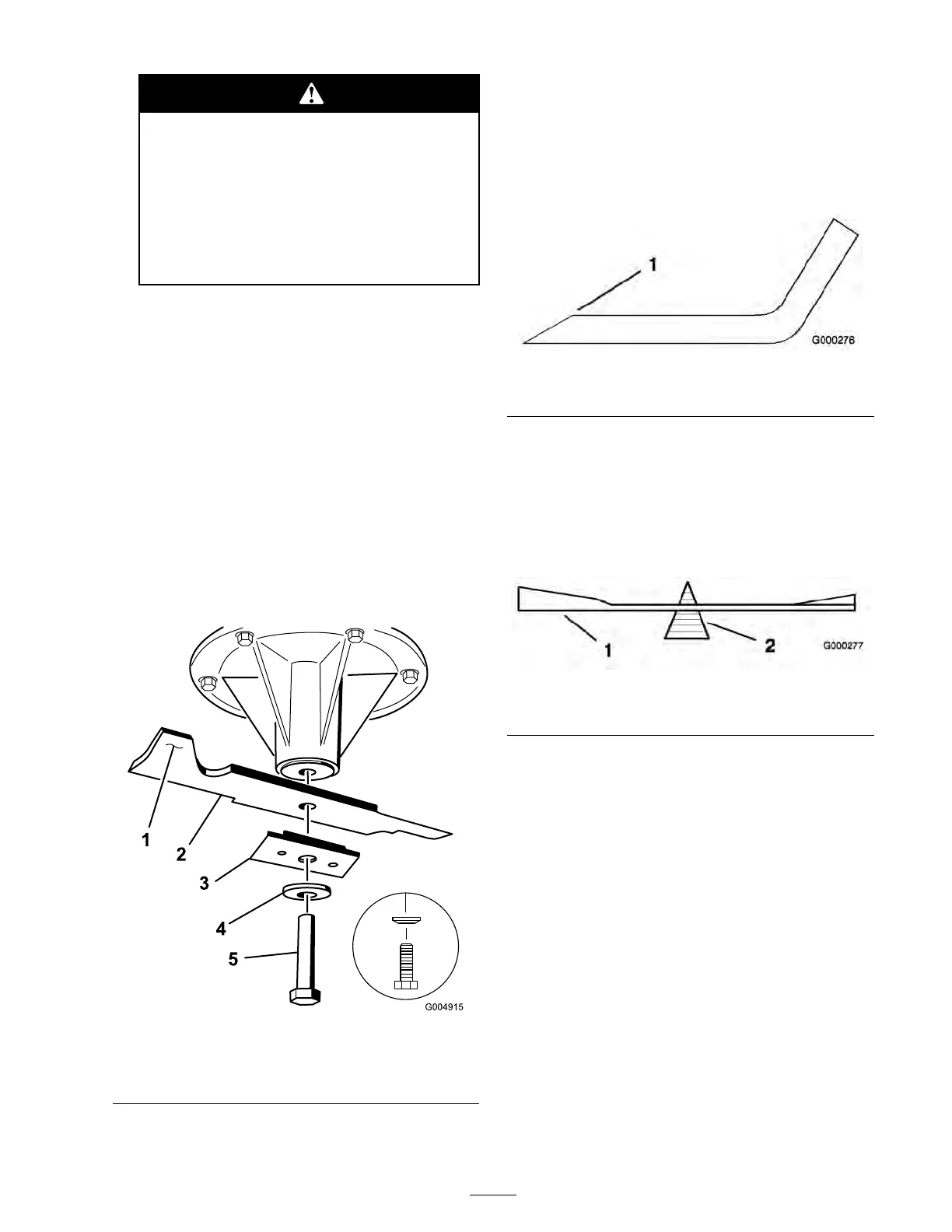

1. Use a file to shar pen the cutting edg e at both

ends of the blade ( Figure 70 ). Maintain the

original angle . T he blade retains its balance if

the same amount of material is remo v ed from

both cutting edg es .

Figure 70

1. Sharpen at original angle

2. Chec k the balance of the blade b y putting it on

a blade balancer ( Figure 71 ). If the blade sta ys

in a horizontal position, the blade is balanced

and can be used. If the blade is not balanced,

file some metal off the end of the sail area only

( Figure 69 ). R e peat this procedure until the

blade is balanced.

Figure 71

1. Blade 2. Balancer

Installing the Blades

1. Install the blade onto the spindle shaft

( Figure 69 ).

Important: T he sail par t of the blade

must be pointing up w ard, to w ard the

inside of the mo w er to ensur e pr oper

cutting ( Figur e 69 ).

2. Install the blade , stiffener , cur v ed w asher , and

blade bolt ( Figure 69 ).

3. T or que the blade bolt to 85-110 ft-lb (115-140

N•m).

Correcting the Mower

Quality of Cut

If one dec k blade cuts lo w er than the other , cor rect

as follo ws .

51

Loading...

Loading...