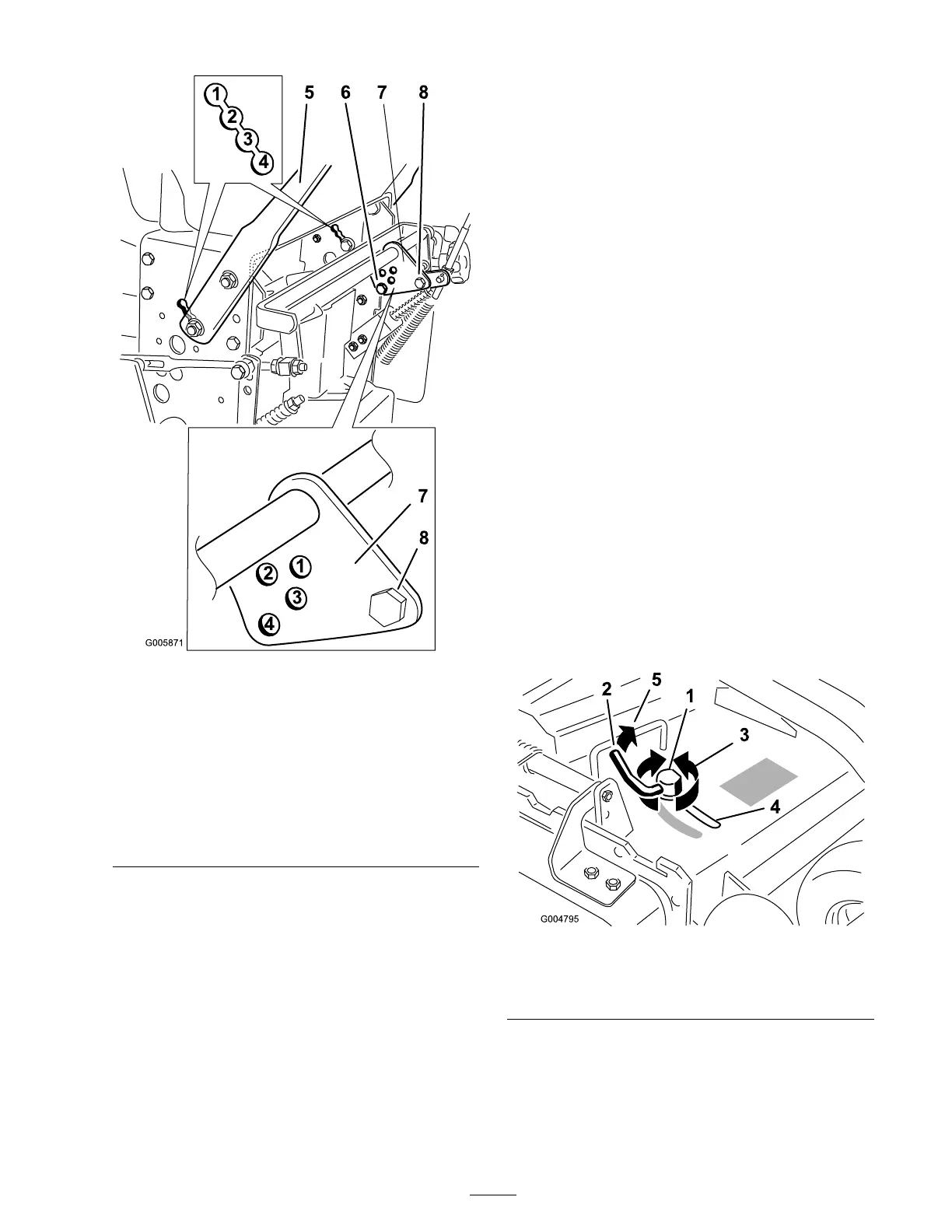

Figure 19

1. Match the hole in speed

control crank with handle

height

5. Handle

2. Match the hole in speed

control crank with handle

height

6. Front bolt

3. Match the hole in speed

control crank with handle

height

7. Speed control crank

4. Match the hole in speed

control crank with handle

height

8. Back bolt

11. Adjust the swi v el on the speed control rod and

tighten the n uts ag ainst the swi v el ( Figure 17 ).

12. Adjust the control rod length b y rotating the

control rod in the rod fitting ( Figure 17 ).

13. Install the hair pin cotter betw een dri v e

lev ers and neutral loc ks and into clevis pins

( Figure 16 ).

Note: Mak e sure the clevis pins are inser ted

into the neutral loc ks .

14. P erfor m the h y draulic linkag e adjustments

when the handle height is c hang ed; refer

Hy draulic Linkag e Adjustments .

Adjusting the Flow Bafe

T he mo w er disc harg e flo w can be adjusted for

different types of mo wing conditions . P osition the

cam loc k and baffle to gi v e the best quality of cut.

1. Diseng ag e the PTO , mo v e the motion control

lev ers to the neutral loc k ed position and set

the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

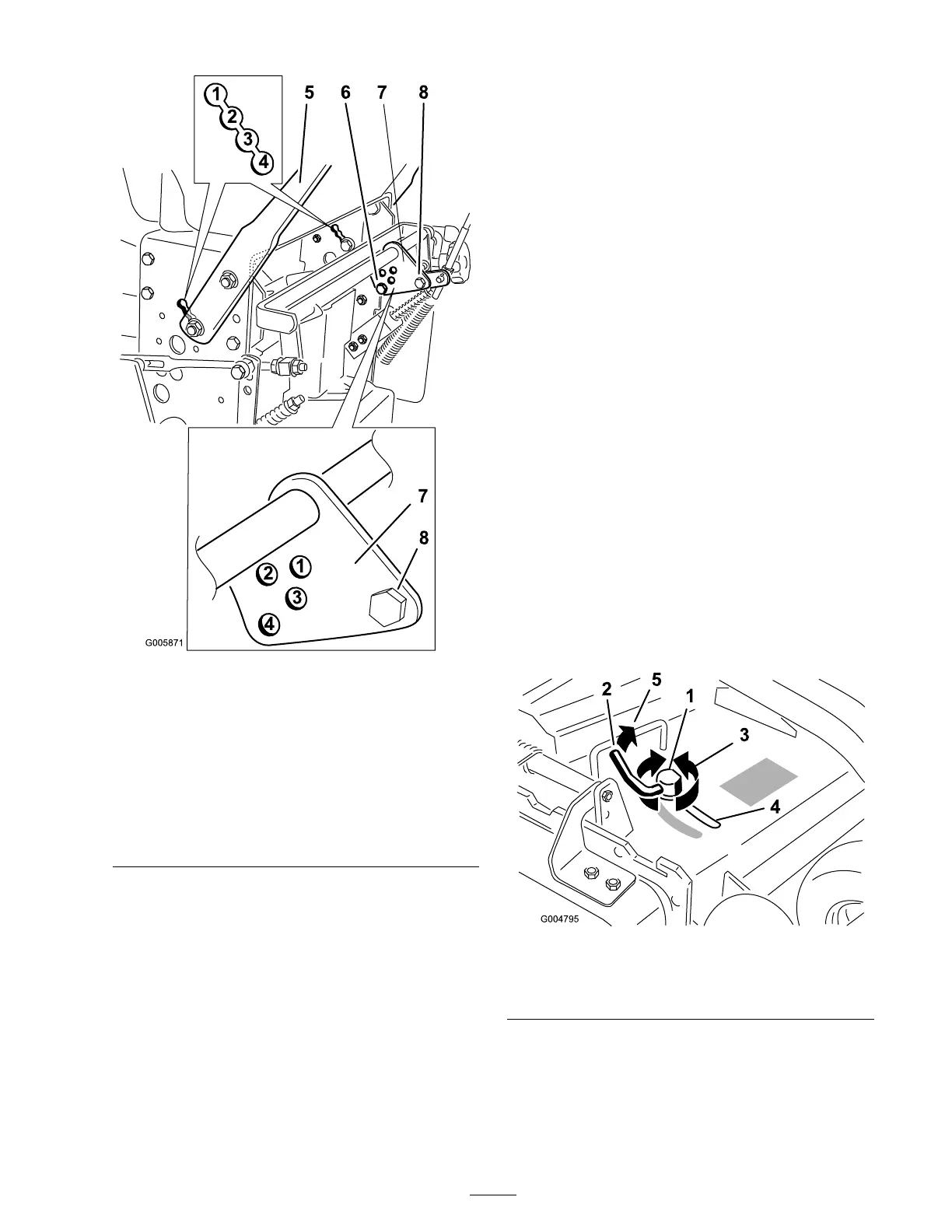

3. T o adjust the cam loc k, swing the lev er up to

loosen the cam loc k ( Figure 20 ).

4. Adjust the baffle and cam loc k in the slot to

the desired disc harg e flo w .

5. Swing the lev er bac k o v er to tighten the baffle

and cam loc k ( Figure 20 ).

6. If the cam does not loc k the baffle into place

or it is too tight, loosen the lev er and then

rotate the cam loc k. Adjust the cam loc k until

the desired loc king pressure is ac hiev ed.

Figure 20

1. Cam lock

3. Rotate cam to increase or

decrease locking pressure

2. Lever

4. Slot

Positioning the Flow Bafe

T he follo wing figures are only recommendations

for use . Adjustments will v ar y b y g rass type ,

moisture content, and height of g rass .

23

Loading...

Loading...