If the engine has been r unning , pr essuriz ed

hot coolant can escape when the radiator

cap is r emo v ed and cause bur ns.

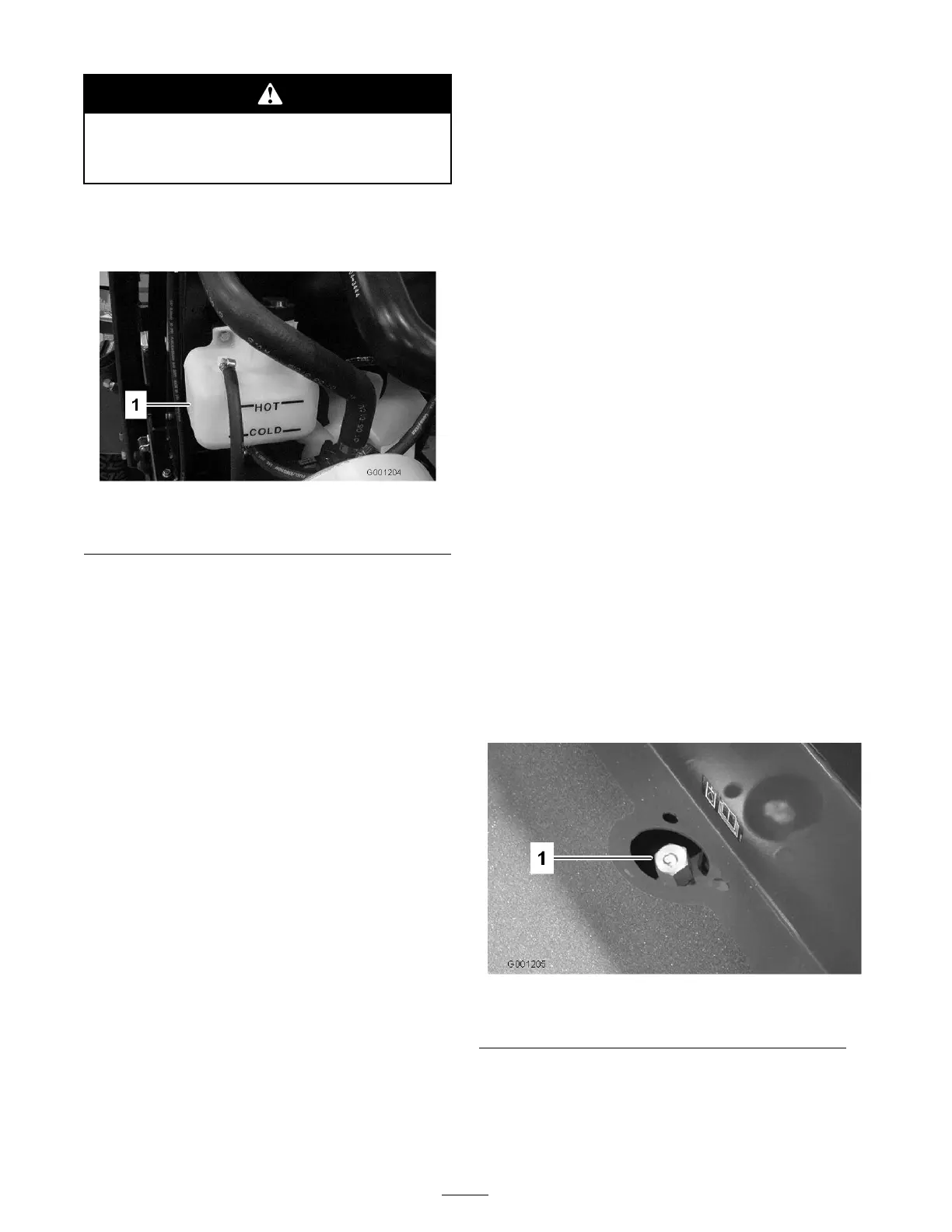

1. Chec k the lev el of the coolant in the expansion

tank ( Figure 21 ). T he coolant lev el should be

betw een the marks on the side of the tank.

Figure 21

1. Expansion tank

2. If coolant lev el is lo w , remo v e expansion tank

cap and re plenish the system. Do not o v erfill .

3. Install expansion tank cap .

Checking the Hydraulic

System

T he mac hines reser v oir is filled at the factor y

with appro ximately 5 quar ts (4.7 l) of high quality

h y draulic fluid. Chec k the lev el of the h y draulic

fluid before the engine is first star ted and daily

thereafter . T he recommended re placement fluid is

as follo ws:

Toro Premium All Season Hydraulic Fluid

(Available in 5 gallon pails or 55 gallon drums. See

parts catalog or Toro distributor for part numbers.)

Alter nate fluids: If the T oro fluid is not a v ailable ,

other fluids ma y be used pro vided they meet all

the follo wing material proper ties and industr y

specifications . W e do not recommend the use

of synthetic fluid. Consult with y our lubricant

distributor to identify a satisfactor y product

Note: T oro will not assume responsibility for

damag e caused b y improper substitutions , so use

only products from re putable man ufacturers who

will stand behind their recommendation.

Material Properties:

Viscosity, ASTM D445

cSt @ 40°C 44 to 48

cSt @ 100°C 9.1 to 9.8

Viscosity Index ASTM

D2270

140 to 152

Pour Point, ASTM D97

-34°F to -46°F

Industry Specications:

API GL-4, AGCO Poweruid 821 XL, Ford

New Holland FNHA-2-C-201.00, Kubota UDT,

John Deere J20C, Vickers 35VQ25, and Volvo

WB-101/BM

Note: Many h y draulic fluids are almost colorless ,

making it difficult to spot leaks . A red dye additi v e

for the h y draulic system oil is a v ailable in 2/3 oz.

(20 ml) bottles . One bottle is sufficient for 4-6

g al (15-22 1) of h y draulic oil. Order par t n umber

44-2500 from y our authorized T oro distributor .

1. P osition mac hine on a lev el surface . Place

all control in neutral position and star t the

engine . R un engine at lo w est possible RPM to

purg e the system of air . Do not enga ge the

PT O . Cycle steering wheel sev eral times fully

to the left and right. Raise the dec k to extend

lift cylinders , aiming steering wheels straight

forw ard and stop the engine .

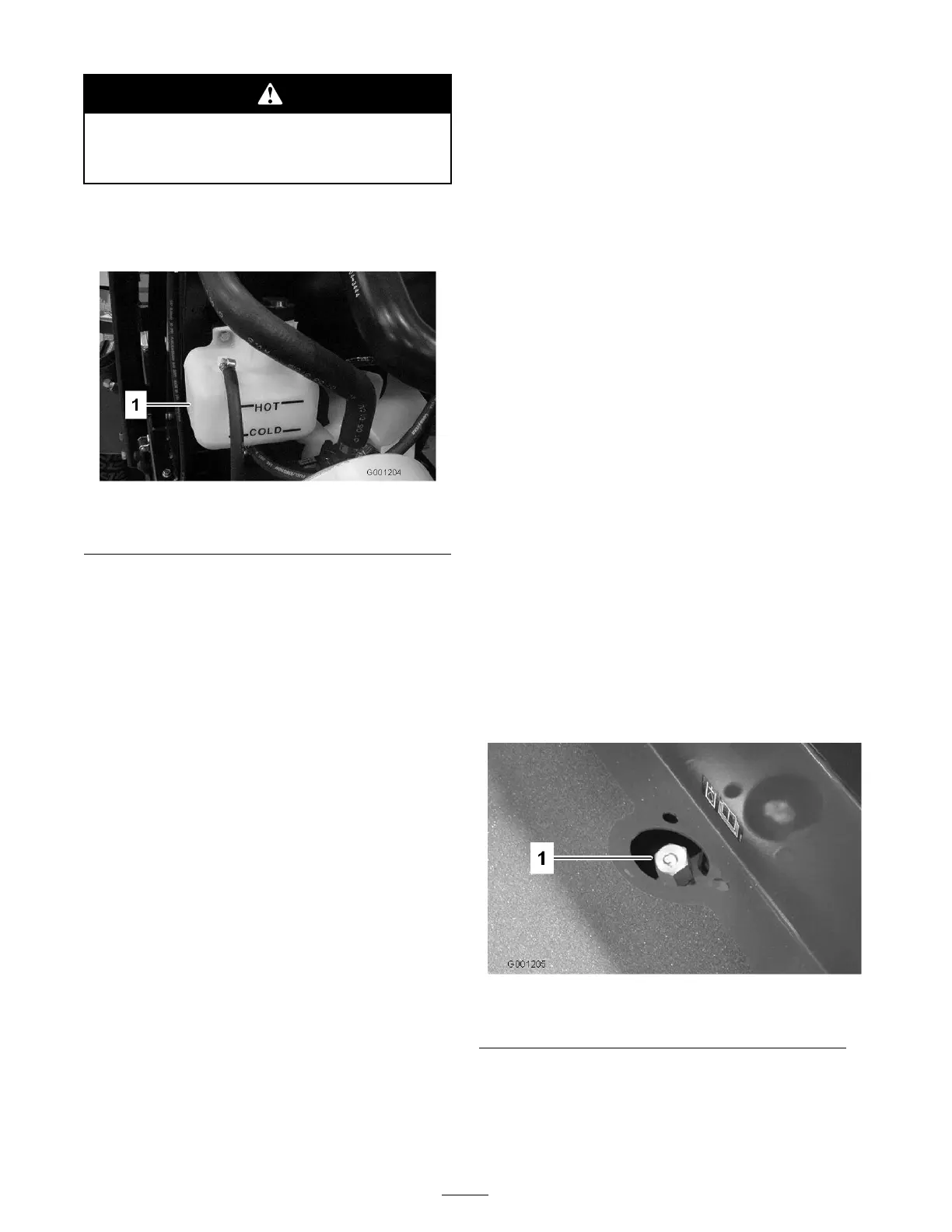

2. R emo v e dipstic k cap ( Figure 22 ) from filler

nec k and wipe it with a clean rag . Screw

dipstic k cap fing er -tight onto filler nec k; then

remo v e it and c hec k lev el of fluid. If lev el is not

within 1/2 inc h (13 mm) from the g roo v e in

the dipstic k, add enough high quality h y draulic

fluid to raise lev el to g roo v e mark. Do not

o v erfill.

Figure 22

1. Hydraulic system reservoir uid/add dipstick cap

3. T hread dipstic k fill cap fing er -tight onto filler

nec k. It is not recommended to tighten cap

with a wrenc h.

4. Chec k all hoses and fittings for leaks .

30

Loading...

Loading...