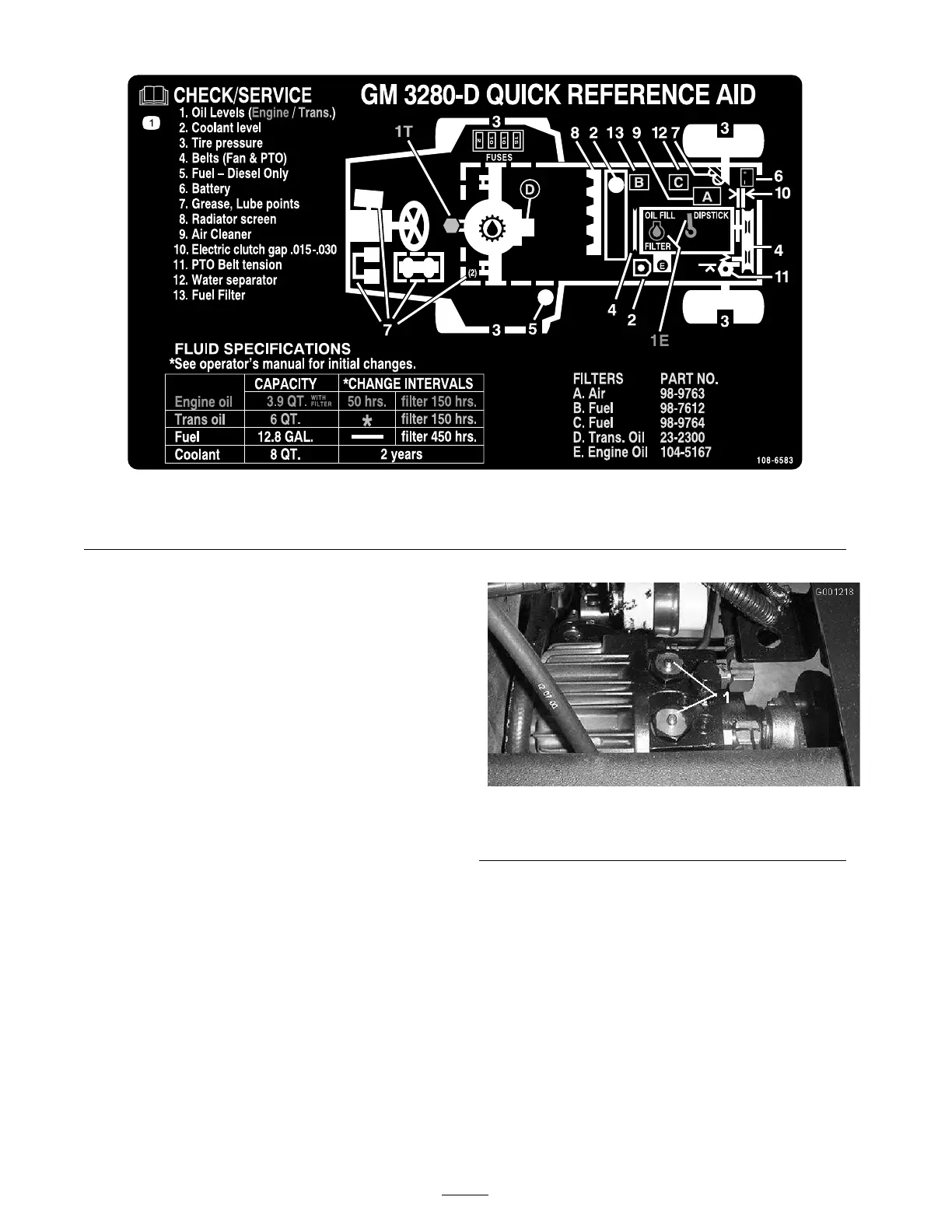

Figure 32

Service Interval Chart

Lubrication

Greasing the Bearings and

Bushings

T he mac hine has g rease fittings that m ust be

lubricated regularly with No . 2 General Pur pose

Lithium Base Grease . If mac hine is operated

under nor mal conditions , lubricate all bearings

and bushings after ev er y 50 hours of operation.

Bearings and bushings m ust be lubricated daily

when operating conditions are extremely dusty and

dir ty . Dusty and dir ty operating conditions could

cause dir t to g et into the bearings and bushings ,

resulting in accelerated w ear . Lubricate g rease

fitting immediately after ev er y w ashing, reg ardless

of inter v al specified.

Apply a liberal coating of g rease to the c hec k v alv e

pins once eac h year ( Figure 33 ). Also g rease the

bearings in the rear axle ev er y 500 hours , or yearly ,

whic hev er comes first (not sho wn).

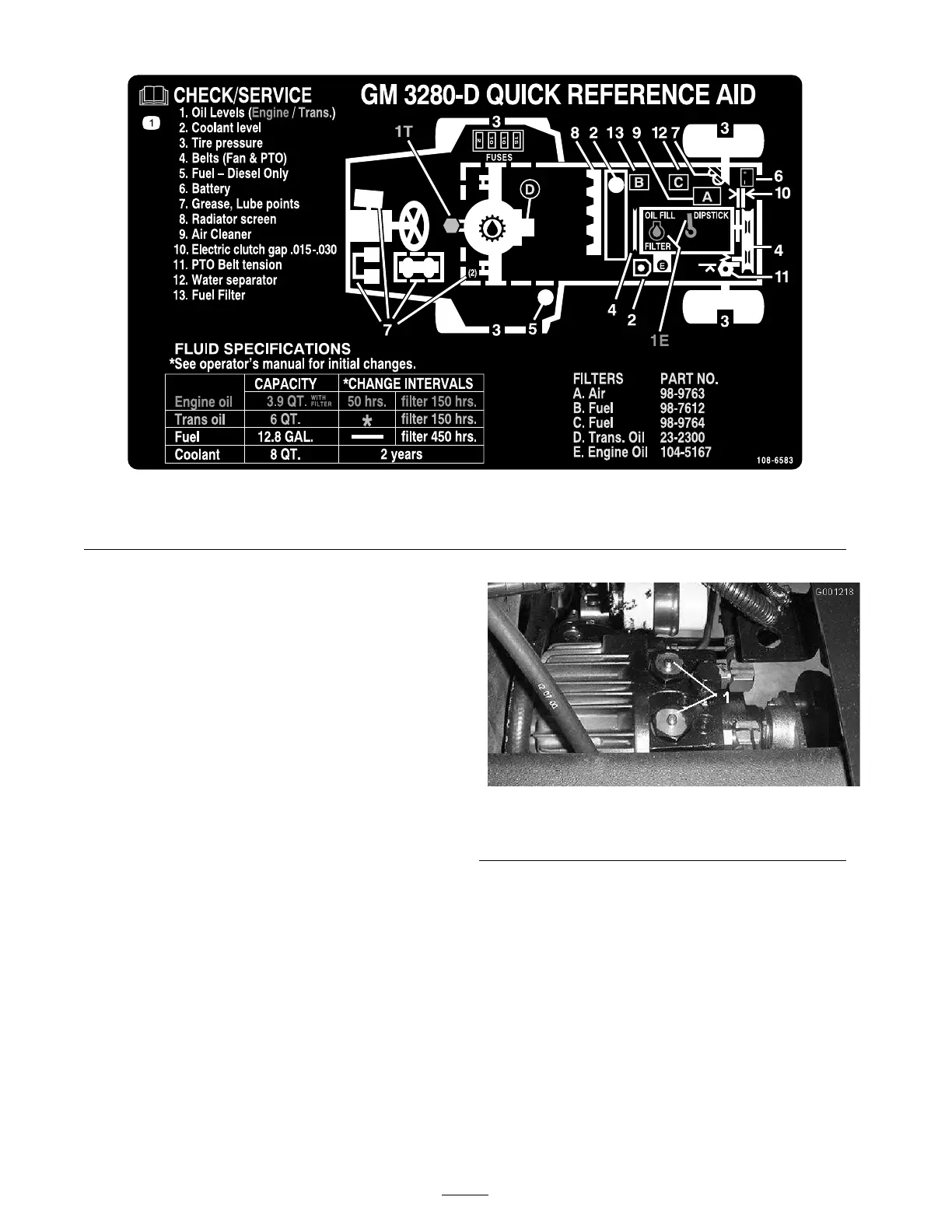

Figure 33

1. Transmission check valve by-pass pins (2)

1. Wipe g rease fitting clean so foreign matter

cannot be forced into the bearing or bushing .

2. Pump g rease into the bearing or bushing .

3. Wipe up ex cess g rease .

T he bearing and bushing lubrication points are as

follo ws:

• PTO uni v ersal shaft ( Figure 34 )

40

Loading...

Loading...