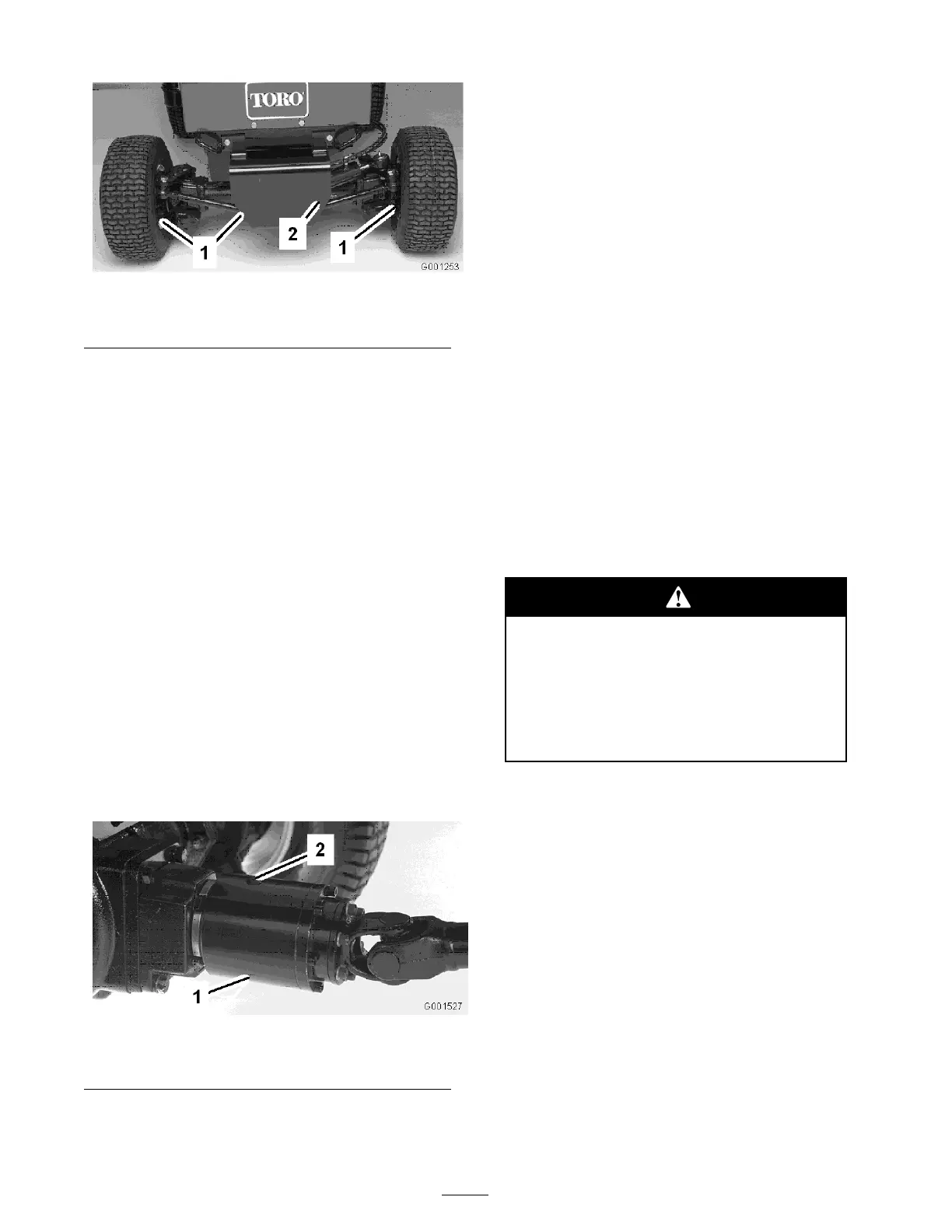

Figure 52

1. Drain plugs (3)

2. Tie rod

3. R emo v e the plugs allo wing the oil to drain into

drain pans .

4. After the oil is drained, apply thread loc king

compound on the drain plug threads and install

them in axle .

5. Fill the axle with lubricant; refer to Chec king

the R ear Axle Lubricant.

Changing the Bidirectional

Clutch Lubricant (Model

30309 only)

Chang e the oil in the bidirectional clutc h after

ev er y 450 hours of operation.

1. P osition the mac hine on a lev el surface .

2. Clean the area around the c hec k plug on the

bidirectional clutc h.

3. R otate the clutc h so that the c hec k plug is

positioned do wnw ard ( Figure 53 ).

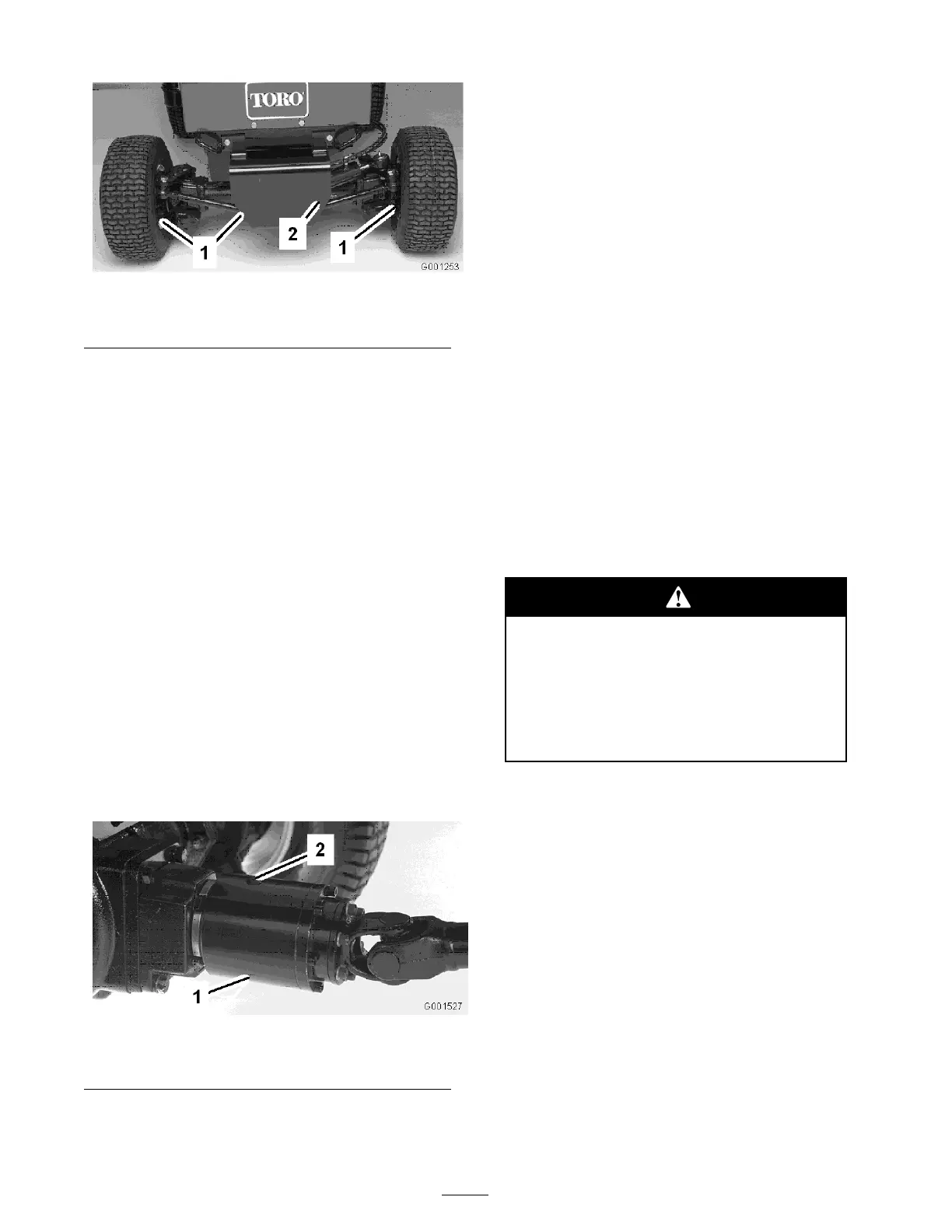

Figure 53

1. Bidirectional clutch 2. Check plug

4. R emo v e the c hec k plug allo wing all lubricant

to flo w into a drain pan.

5. R otate the clutc h so that the c hec k plug is

positioned at 4 O’cloc k.

6. Add Mobil Fluid 424 until the lubricant lev el is

up to the hole in the clutc h. T he clutc h should

be appro ximately 1/3 full.

7. Install the c hec k plug .

Note: Do not use engine oil (i.e . 10W30) in

the bidirectional clutc h. Anti-w ear and extreme

pressure additi v es will cause undesirable clutc h

perfor mance .

Adjusting the Traction Drive

for Neutral

If the mac hine mo v es when the traction pedal is in

the neutral position, adjust the traction cam.

1. P ark the mac hine on a lev el surface and tur n

the engine off .

2. Raise one front wheel and one rear wheel off

of the floor and place suppor t bloc ks under

the frame .

If the machine is not suppor ted

adequatel y , it may accidentall y f all,

injuring an y one under the machine.

One fr ont wheel and one r ear wheel

must be raised of f of the g r ound or the

machine will mo v e during adjustment.

3. Loosen the retaining screw on the opposite

side of the traction adjustment cam ( Figure 54 ).

48

Loading...

Loading...