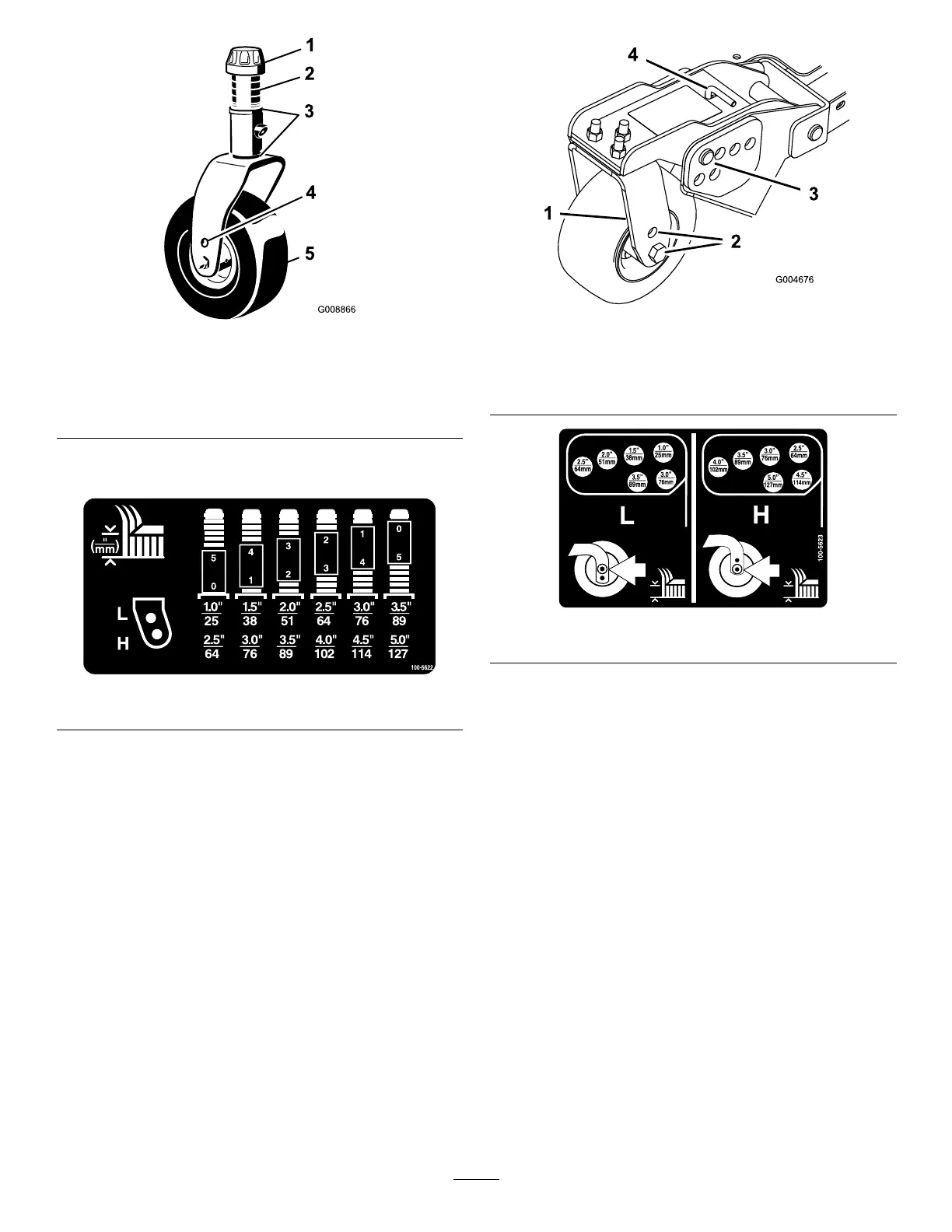

g008866

Figure22

1.Tensioningcap4.Toaxlemountinghole

2.Spacers5.Castorwheel

3.Shims

Refertothefollowingcharttodeterminethe

combinationsofspacersforthesetting.

decal100-5622nc

Figure23

3.Pushthecastorspindlethroughthecastorarm.

Installtheshims(asoriginallyinstalled)andthe

remainingspacersontothespindleshaft.Install

thetensioningcaptosecuretheassembly.

4.Removethehairpincotterandclevispinsfrom

thecastorpivotarms(Figure24).

5.Rotatetensionrodtoraiseorlowerpivotarm

untilholesarealignedwithselectedheight-of-cut

bracketholesinthecuttingunitframe(Figure

24andFigure25).

6.Inserttheclevispinsandinstallthehairpin

cotters.

7.Rotatetensionrodcounterclockwise(nger

tight)toputtensiononadjustment.

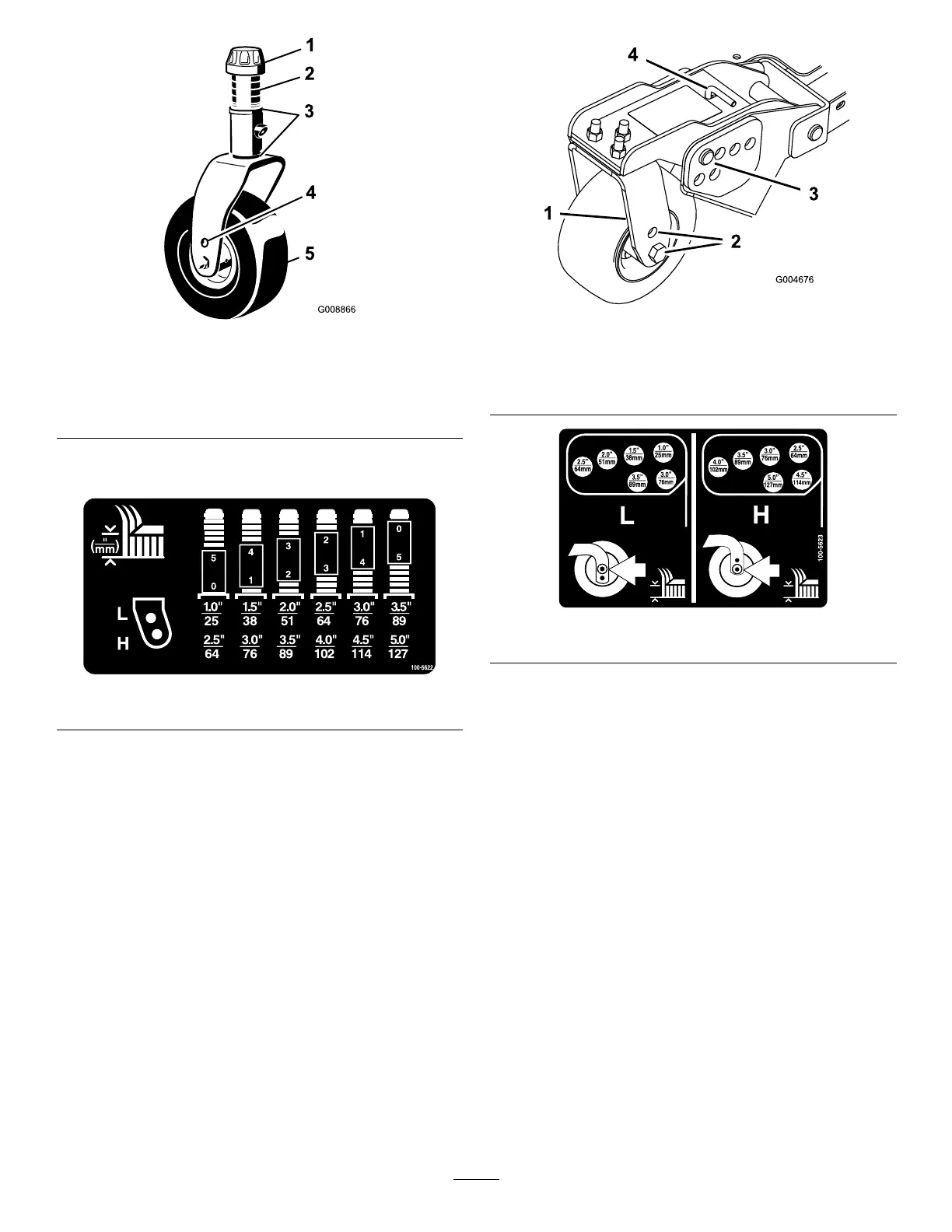

g004676

Figure24

1.Castorpivotarm3.Clevispinandhairpin

cotter

2.Axlemountingholes4.Tensionrod

decal100-5623nc

Figure25

AdjustingtheSkids

Theskidsshouldbemountedinthelowerposition

whenoperatingatheightsofcutgreaterthan64

mm(2-1/2inches)andinthehigherpositionwhen

operatingatheightsofcutlowerthan64mm(2-1/2

inches).

Adjusttheskidsbyremovingtheangeboltand

nuts,positioningthemasdesired,andinstallingthe

fasteners(Figure24).

31

Loading...

Loading...