ToroPremiumTransmission/HydraulicTractorFluid

(Availablein5gallonpailsor55gallondrums.Seeparts

catalogorTorodistributorforpartnumbers.)

Alternativeuids:Ifthespecieduidisnotavailable,

otheruniversaltractorhydraulicuids(UTHF)may

beused,buttheymustbeonlyconventional,

petroleum-basedproducts,notsyntheticsor

biodegradableuids.Thespecicationsmustfall

withinthelistedrangeforallofthefollowingmaterial

propertiesandtheuidshouldmeetlistedindustry

standards.Checkwithyouruidsuppliertoseeifthe

uidmeetsthesespecications.

Note:T orowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonly

productsfromreputablemanufacturerswhowillstand

behindtheirrecommendation.

MaterialProperties:

Viscosity,ASTMD445cSt@40°C(104°F)55to62

ViscosityIndexASTMD2270

140to152

PourPoint,ASTMD97-37°Cto-43°C(-35°Fto-46°F)

IndustrySpecications:

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT ,JohnDeereJ20C,Vickers

35VQ25,andVolvoWB-101/BM

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein20ml(2/3oz)

bottles.1bottleissufcientfor15to22L(4to6US

gallons)ofhydraulicuid.OrderPartNo.44-2500

fromyourauthorizedTorodistributor.

MaintainingtheConveyor

BeltSystem

CheckingtheConveyorBeltand

Rollers

•Checkthattheconveyorbeltistrackingstraighton

therollersanddoesnotslip.Makeadjustmentsif

necessary.RefertoAdjustingtheTrackingofthe

ConveyorBelt(page40).

•Checkthefrontandrearrollerbearingsevery2

monthsforwearorvisibledamage.

•Checktheconditionandtensionofthedrivechain

andthesprockets.

Important:Checkfortrappedspreading

materialbetweenconveyorbed,belt,and

rollers.RefertoWashingtheMachine(page

41).

AdjustingtheConveyorBelt

Tension

Performthetensioningprocedureonlyifthebeltis

slipping,ifithasbeenreplaced,orifithasbeen

loosenedtoreplaceotherparts.

1.Placethebelt’sV-guideintheguidesofthefront

andrearrollers.

2.Tightenthe2beltadjustmentnutsevenlyuntil

thebeltissnug.

Note:Ifnecessary,removethefrontidlerroller

coverandtherearchutecover.

3.Fullyloadthemachinewiththeheaviestmaterial

youexpecttouse.

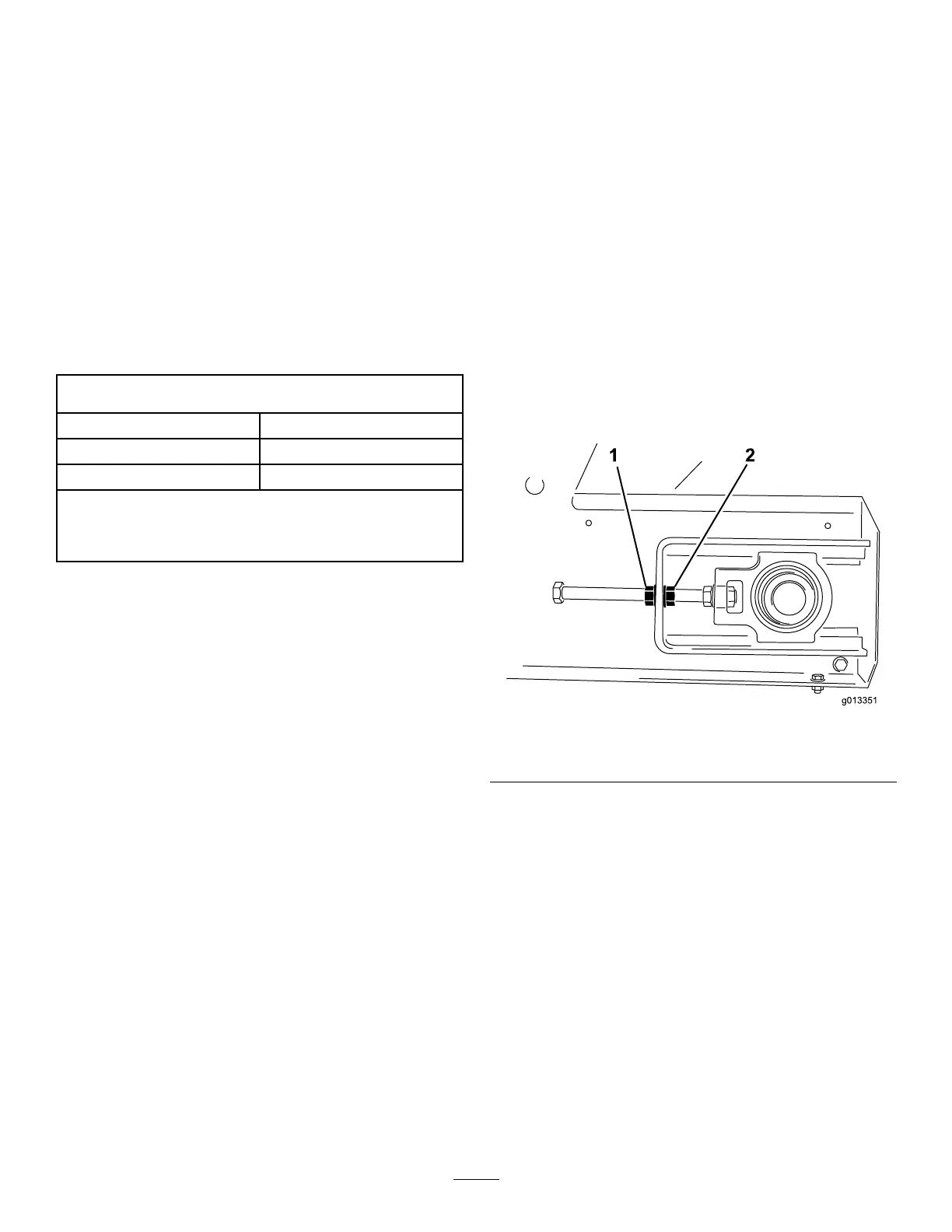

4.With2wrenches,holdtheendofthetensioner

rodstationaryandthenloosenthelockingnut,

whichisthenutclosesttotheendoftherod

(Figure55).

g013351

Figure55

1.Lockingnut2.Adjusternut

5.Turntheconveyorbeltonandcheckifthebelt

isslipping.

6.Ifso,stopthebeltandtightenbothadjusternuts

halfaturn.Donotover-tension.

7.Repeatsteps5and6untiltheconveyorbelt

stopsslipping.

8.Tightenthelockingnutsandinstalltheyellow

safetycovers

AdjustingtheTrackingofthe

ConveyorBelt

Theconveyorbeltsystemisself-tracking.Boththe

frontandrearrollershaveagrooveinthemiddlefor

thebelt’sV-guidetorunin.Sometimes,thebeltmay

40

Loading...

Loading...