machinemayperformbetterwithSmartPowerset

toOFF.

UnderstandingtheSmart

LoadSystem

Whenyouraisetheloaderarmsaboveacertainlevel

(slightlyaboveparalleltotheground),theSmart

Loadsystemwillautomaticallyreducethemaximum

tractionspeedto50%.Theenginespeedwillremain

thesame.

Note:Ifthemaximumtractionspeedisalreadyset

50%orbelowintheInfoCenter,thetractionspeedwill

notautomaticallychange.

Fortelescopingmachines:

TheSmartLoadsystemalsomeasuresthehydraulic

pressureintheloaderarmcylinderstodeterminethe

maximumreach.

Whenyouextendtheloaderarmstothemaximum

reachforthearmheightandloadweight,the

InfoCenterwilldisplaytheSmartLoadicon(Figure

30)andashtheindicatorlight,analarmwillbeep,

andthearmswillstopextending.

Toextendtheloaderarmsfurther,lightentheload.

g270732

Figure30

AfterOperation

AfterOperationSafety

•Shutofftheengine,removethekey,waitforall

movementtostop,andallowthemachinetocool

beforeadjusting,cleaning,storing,orservicingit.

•Cleandebrisfromtheattachments,drives,

mufers,andenginetohelppreventres.Clean

upoilorfuelspills.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

MovingaNon-Functioning

Machine

Inanemergency,themachinecanbemovedforward

byactuatingthebypassvalveinthehydraulicpump

andpushingortowingthemachine.

Important:Donottoworpullthemachine

withoutbypassingtheparkingbrakeoryouwill

damagethehydraulicsystem.

1.Shutofftheengineandremovethekey.

2.Removethebottomplate;refertoRemovingthe

BottomPlate(page31)

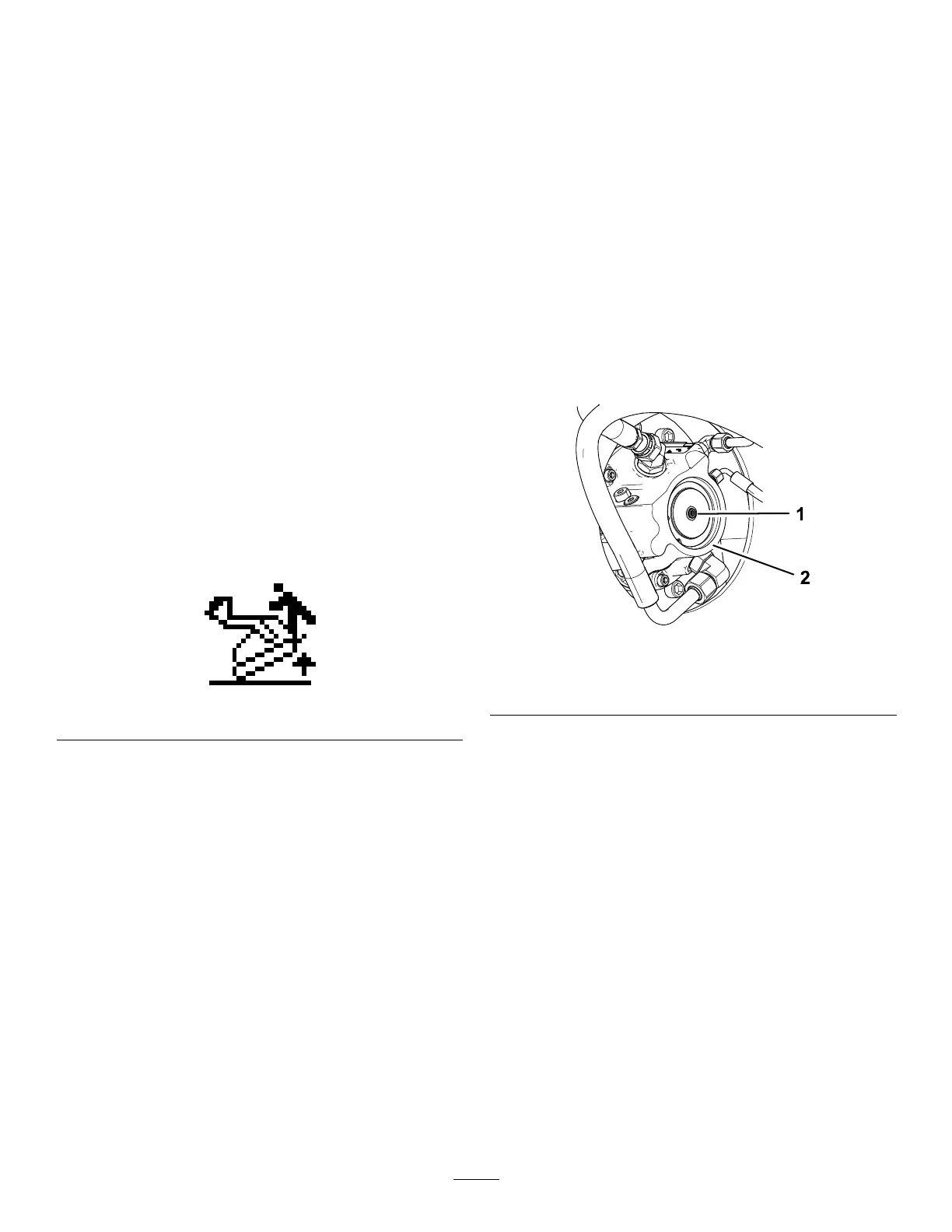

3.Foreachdrivemotor,removetheplugandinstall

ascrew(M8–1.25x40mm)andwasher(M8x

16mm)initsplace(Figure31).Hand-tighten

thehardware.

g263991

Figure31

1.Removethisplugand

installascrewandwasher.

2.Trackdrivemotor

4.Usehandtoolstorotatethehardwareclockwise

untilthebrakeisreleasedoryoucannotrotate

thescrew(Figure30).

5.Ontheleftsideofthehydraulicpump,rotatethe

4bypassvalves3fullturnscounter-clockwiseto

openandallowtheoiltobypassinternally.

Note:Donotopenmorethan3turns.Because

uidisbypassed,youcanslowlymovethe

machinewithoutdamagingthetransmission.

25

Loading...

Loading...