Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

MaintenanceSafety

•Parkthemachineonalevelsurface,disengage

theauxiliaryhydraulics,lowertheattachment,

engagetheparkingbrake(ifequipped),shut

offtheengine,andremovethekey.Waitforall

movementtostopandallowthemachinetocool

beforeadjusting,cleaning,storing,orrepairingit.

•Cleanupoilorfuelspills.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthecomponentswhen

required.

•Carefullyreleasepressurefromcomponents

withstoredenergy;refertoRelievingHydraulic

Pressure(page49).

•Disconnectthebatterybeforemakinganyrepairs;

refertoUsingtheBattery-DisconnectSwitch(page

39).

•Keepyourhandsandfeetawayfromthemoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Donottamperwiththesafetydevices.

•Attachmentscanchangethestabilityandthe

operatingcharacteristicsofthemachine.

•UseonlygenuineTororeplacementparts.

•Ifanymaintenanceorrepairrequirestheloader

armstobeintheraisedposition,securethearms

intheraisedpositionwiththehydraulic-cylinder

lock(s).

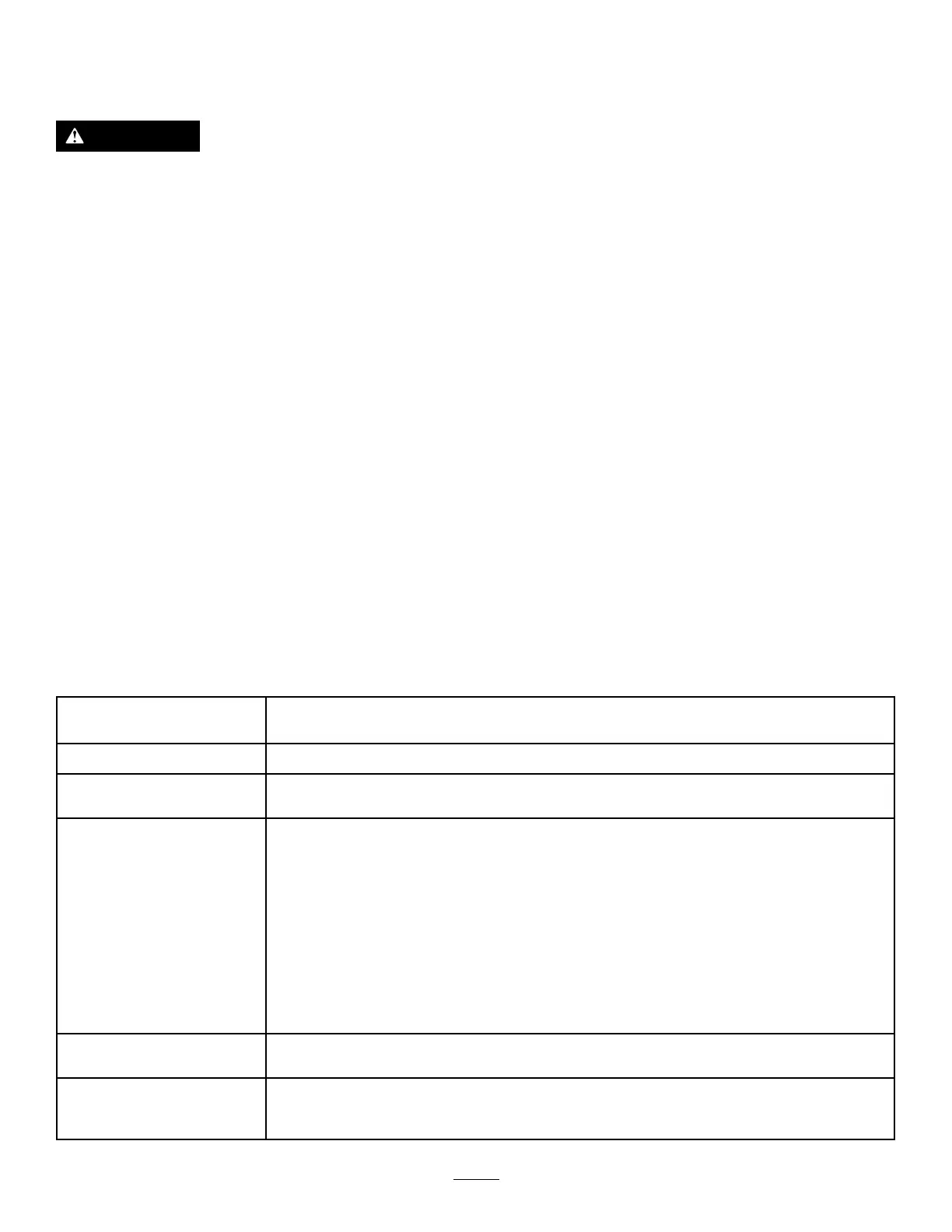

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst8hours

•Checkandadjustthetracktension.

Aftertherst50hours

•Changetheengineoilandlter.

•Checkandadjustthetracktension.

Beforeeachuseordaily

•Greasethemachine.(Greaseimmediatelyaftereverywashing.)

•Checkandlubricatethequick-attachlinkagesusingspraylubricant.

•Checktheair-lter-serviceindicator.

•Checktheengine-oillevel.

•Cleanthetracksandcheckforexcessivewearandpropertension.

•Cleanthescreen,oilcooler,andfrontoftheradiator(moreoftenindirtyordusty

conditions).

•Checkthecoolantlevelintheexpansiontank.

•Checkandcleantheradiatorscreen

•Checktheconditionofthealternatorbelt.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

Every25hours

•Checkthehydraulic-uidlevel.

•Torquetheloaderarmadjustmentscrews(telescopingmachinesonly).

Every50hours

•Drainwaterandothercontaminantsfromthefuellter/waterseparator.

•Checkthebatterycondition.

•Checkandadjustthetracktension.

28

Loading...

Loading...