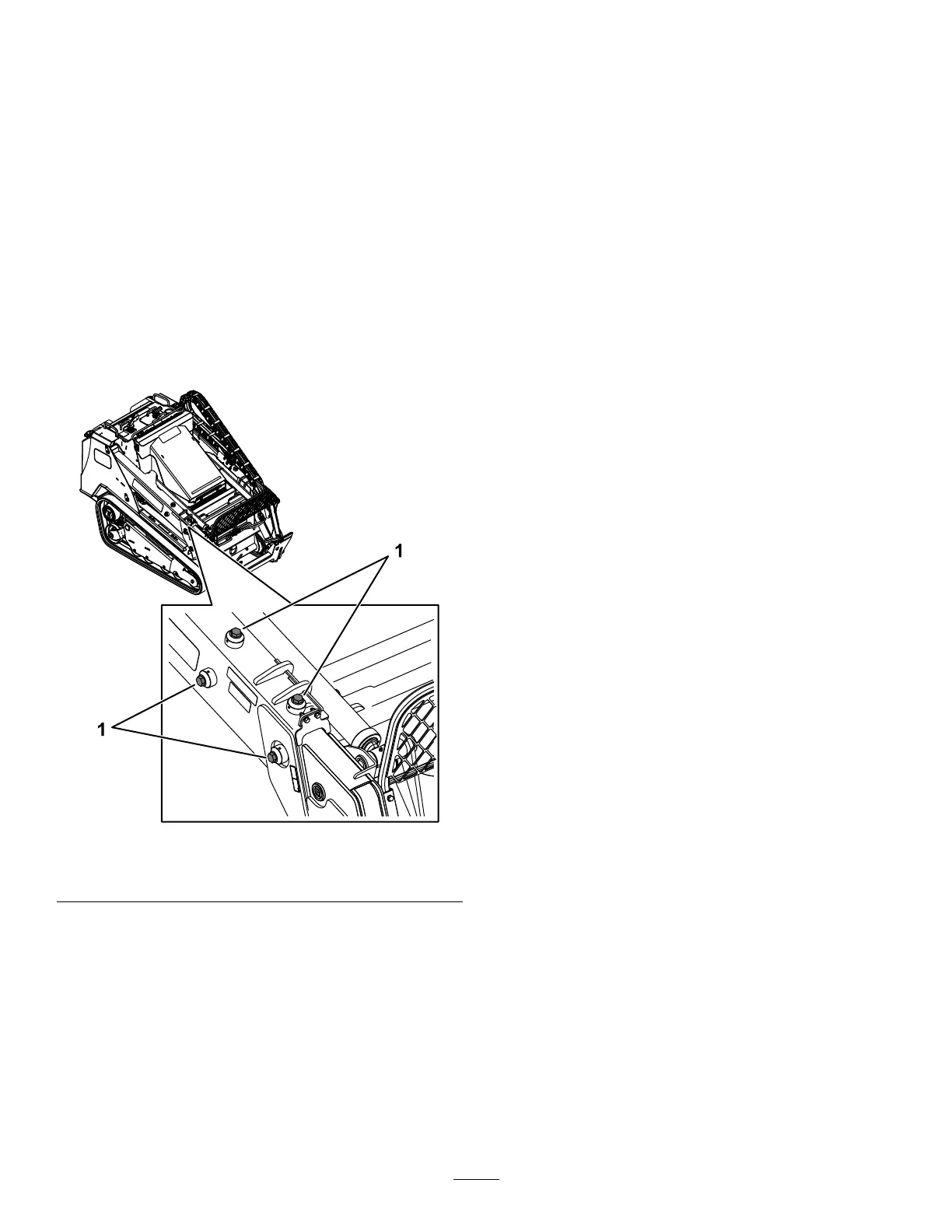

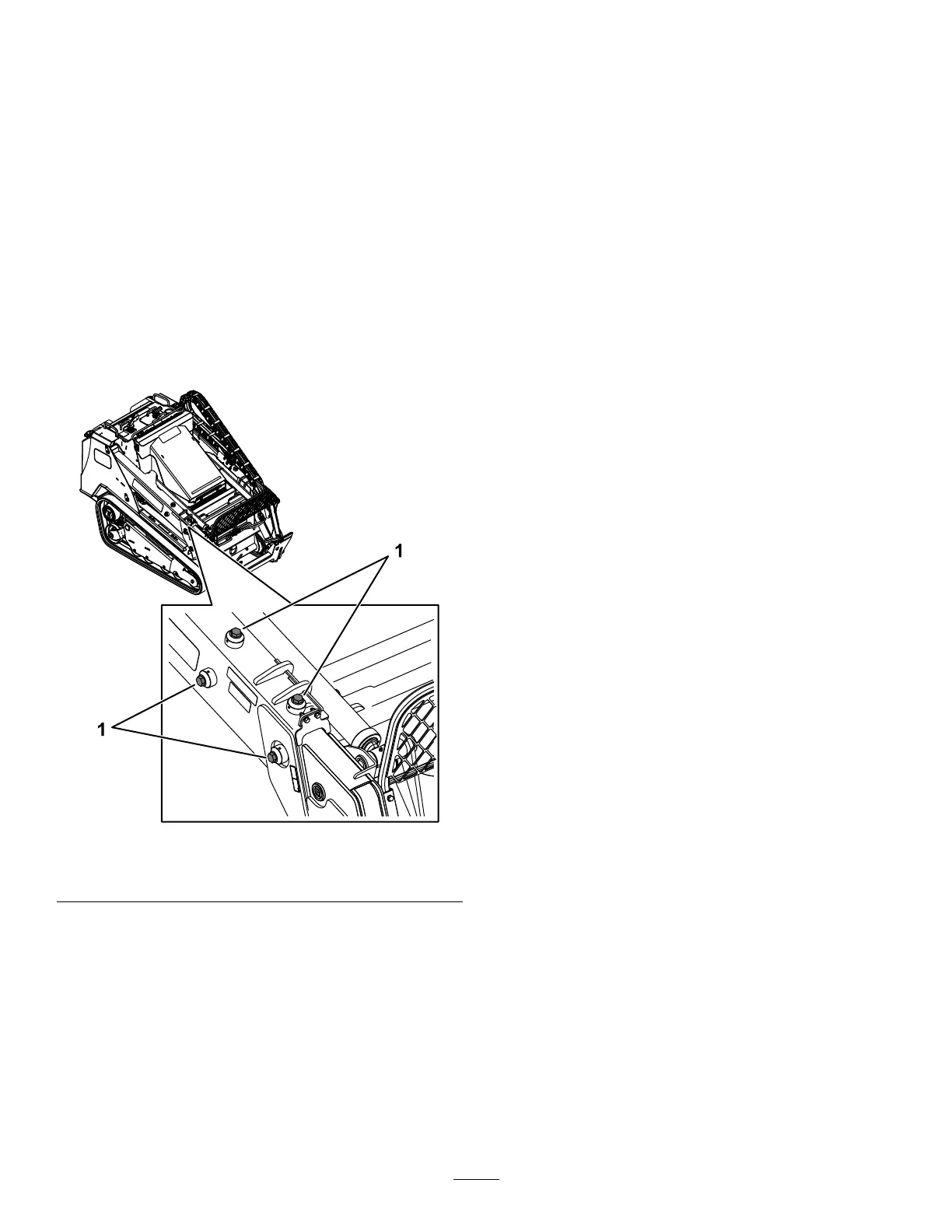

LoaderMaintenance

TorquingtheLoaderArm

AdjustmentScrews

TelescopingMachinesOnly

ServiceInterval:Every25hours

Checkthetorquewheneverthelowerloaderarms

rattle.

1.Parkthemachineonalevelsurface.

2.Shutofftheengine,removethekey,andallow

theenginetocool.

3.Oneachloaderarm,loosenthesetscrewonthe

4adjustmentscrews(Figure84).

g263689

Figure84

1.Adjustmentscrew

4.Torquetheadjustmentscrewsto27N∙m(20

ft-lb).

5.Checkthatthelengthoftheadjustmentscrews

thatisprotrudingfromthearmsisequalsideto

side.

6.Applymedium-strengththread-locking

compoundtothesetscrewsandtightenthem

untiltheyjustcontacttheadjustmentscrews.

Important:Donotovertightenthe

setscrews;otherwiseyoumaydamagethe

adjustmentscrewthreads.

Cleaning

RemovingDebris

ServiceInterval:Beforeeachuseordaily

Important:Operatingtheenginewithblocked

screensand/orcoolingshroudsremovedwill

resultinenginedamagefromoverheating.

1.Parkthemachineonalevelsurfaceandlower

theloaderarms.

2.Shutofftheengine,removethekey,andallow

theenginetocool.

3.Openthehoodandsecuretheproprod.

4.Cleananydebrisfromthefrontandside

screens.

5.Wipeawaydebrisfromtheaircleaner.

6.Cleananydebrisbuildupontheengineandin

theoilcoolernswithabrushorblower.

Important:Operatingtheenginewith

blockedscreensand/orcoolingshrouds

removedwillresultinenginedamagedueto

overheating.

7.Cleandebrisfromthehoodopening,mufer,

heatshields,andradiatorscreen(ifapplicable).

8.Closethehood.

53

Loading...

Loading...