28

HDWA-SVX001D-EN

NNOOTTIICCEE

PPrrooooff ooff FFllooww SSwwiittcchh!!

FFaaiilluurree ttoo pprroovviiddee ffllooww sswwiittcchheess oorr jjuummppiinngg--oouutt ooff

sswwiittcchheess ccoouulldd rreessuulltt iinn sseevveerree eeqquuiippmmeenntt

ddaammaaggee..

EEvvaappoorraattoorr aanndd ccoonnddeennsseerr wwaatteerr cciirrccuuiittss rreeqquuiirree

pprrooooff ooff ffllooww sswwiittcchheess..

•• FFaaiilluurree ttoo iinncclluuddee tthhee pprrooooff ooff ffllooww ddeevviicceess aanndd//

oorr jjuummppiinngg oouutt tthheessee ddeevviicceess ccoouulldd ccaauussee tthhee uunniitt

ttoo ssttoopp oonn aa sseeccoonnddaarryy lleevveell ooff pprrootteeccttiioonn..

•• FFrreeqquueenntt ccyycclliinngg oonn tthheessee hhiigghheerr lleevveell

ddiiaaggnnoossttiicc ddeevviicceess ccoouulldd ccaauussee eexxcceessssiivvee tthheerrmmaall

aanndd pprreessssuurree ccyycclliinngg ooff uunniitt ccoommppoonneennttss ((OO--rriinnggss,,

ggaasskkeettss,, sseennssoorrss,, mmoottoorrss,, ccoonnttrroollss,, eettcc..)) aanndd//oorr

ffrreeeezzee ddaammaaggee,, rreessuullttiinngg iinn pprreemmaattuurree ffaaiilluurree ooff

tthhee cchhiilllleerr..

Evaporator and condenser proof of flow switches are

required. These switches are used with control logic to

confirm flow prior to starting a unit and to stop a

running unit if flow is lost. For troubleshooting, a

viewable diagnostic is generated if a proof of flow

switch does not close when flow is required.

Evaporator and Condenser

Water Piping

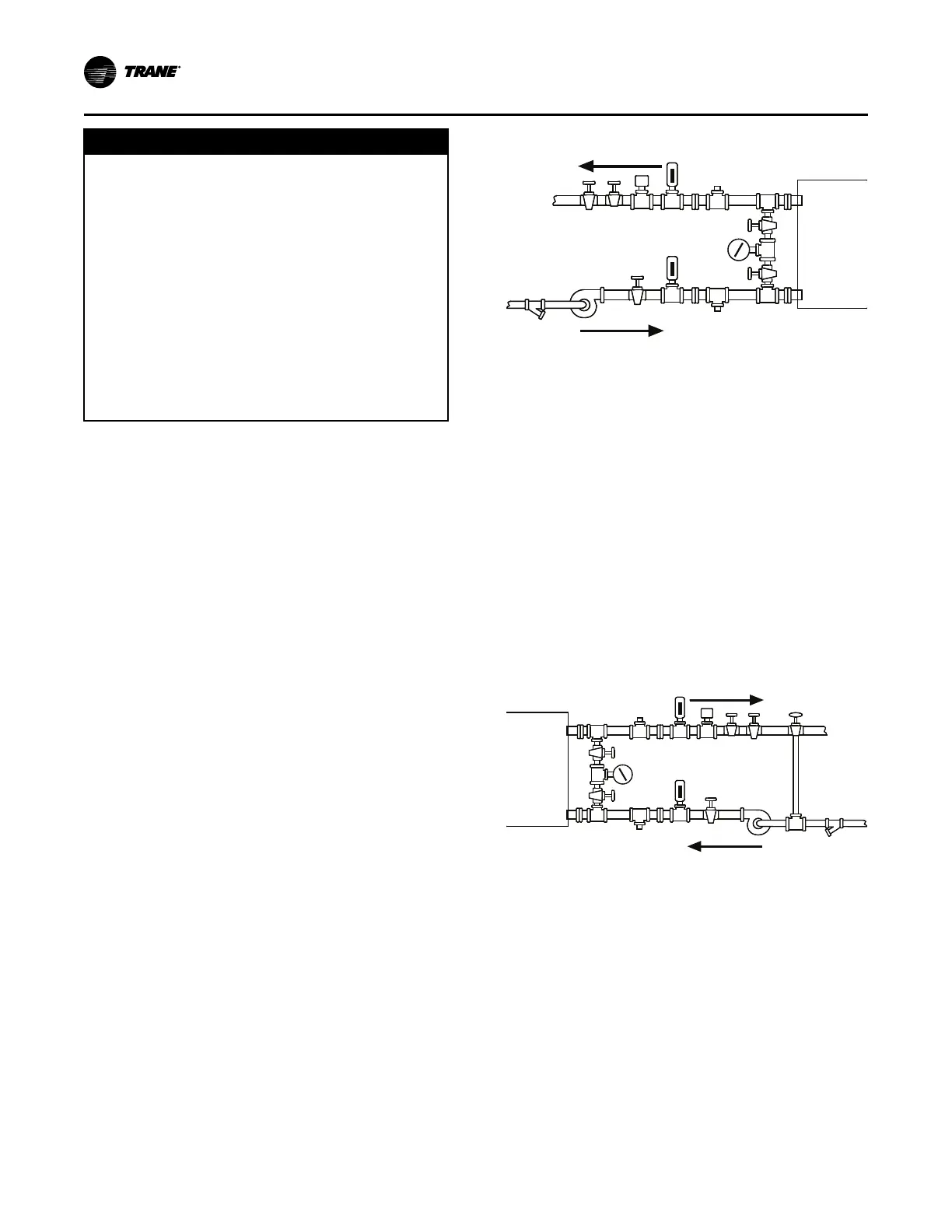

The following two figures illustrate the recommended

(typical) water piping arrangements for the evaporator

and condenser.

Figure 16. Typical evaporator water piping circuit

4

45

53

3

7

2

2 1

9

6

2

2

8

Outlet

Inlet

1. Balancing valve.

2. Gate (Isolation) valve or ball valve.

3. Thermometer (if field supplied).

4. Waterbox nozzle connection.

5. Drain, vent, and anode.

6. Strainer.

7. Chilled water flow switch (5S1). Flow switch 5S1

may be installed in either the entering or leaving leg

of the chilled water circuit.

8. Pump.

9. Pressure gauge. It is recommended to pipe the

gauge between entering and leaving pipes. A

shutoff valve on each side of the gauge allows the

operator to read either entering or leaving water

pressure.

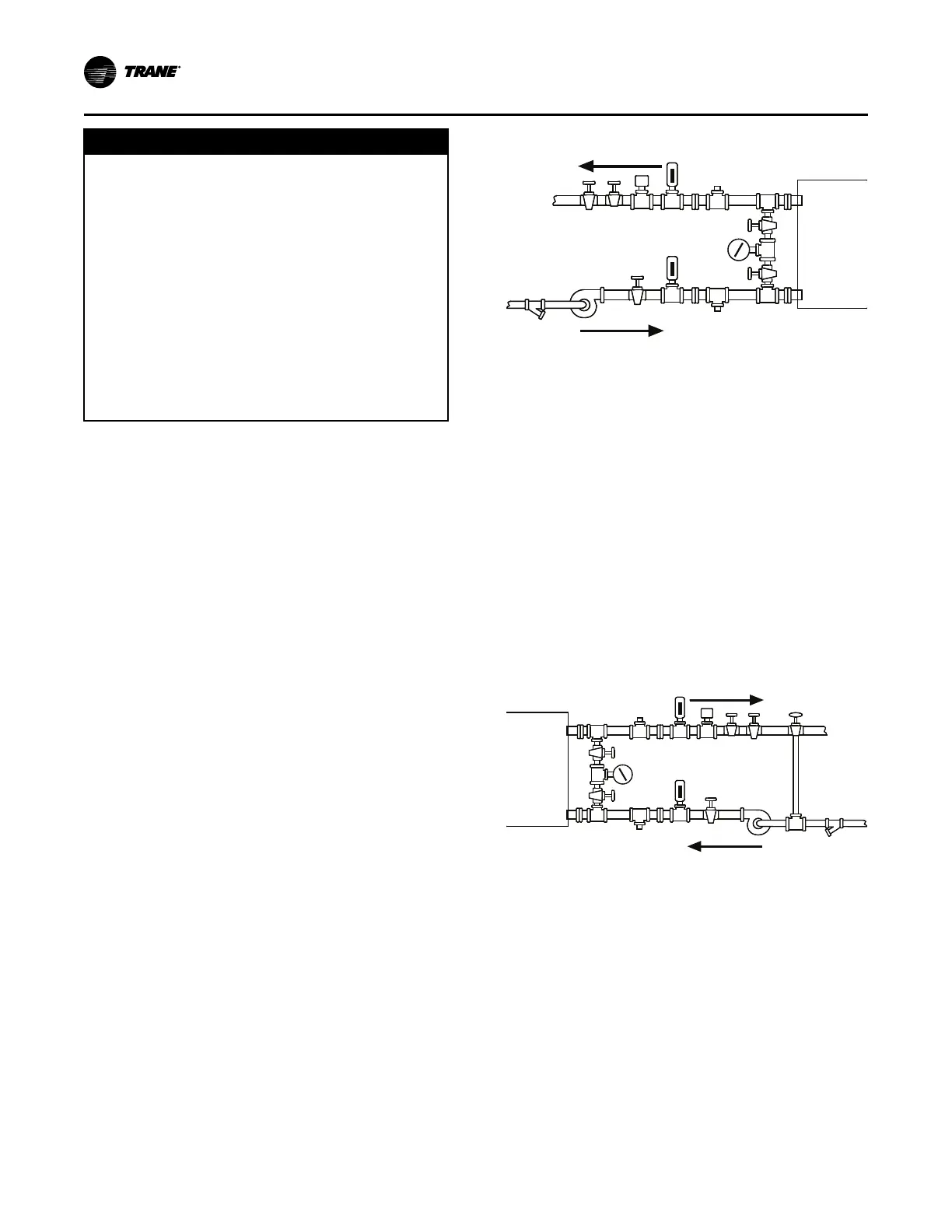

Figure 17. Typical condenser water piping circuits

1 2

3

4 5

6

7 8

92

3

4 5

2

2

10

Outlet

Inlet

1. Balancing valve.

2. Gate (isolation) valve or ball valve.

3. Thermometer (if field supplied).

4. Waterbox nozzle connection.

5. Drain, vent, and anode.

6. Strainer.

7. Condenser water flow switch (5S2). Flow switch

5S2 may be installed in either the entering or

leaving leg of the chilled water circuit.

8. Three-way valve (optional).

9. Condenser water pump.

10. Pressure gauge. It is recommended to pipe a single

gauge between entering and leaving pipes.

IInnssttaallllaattiioonn:: WWaatteerr PPiippiinngg

Loading...

Loading...