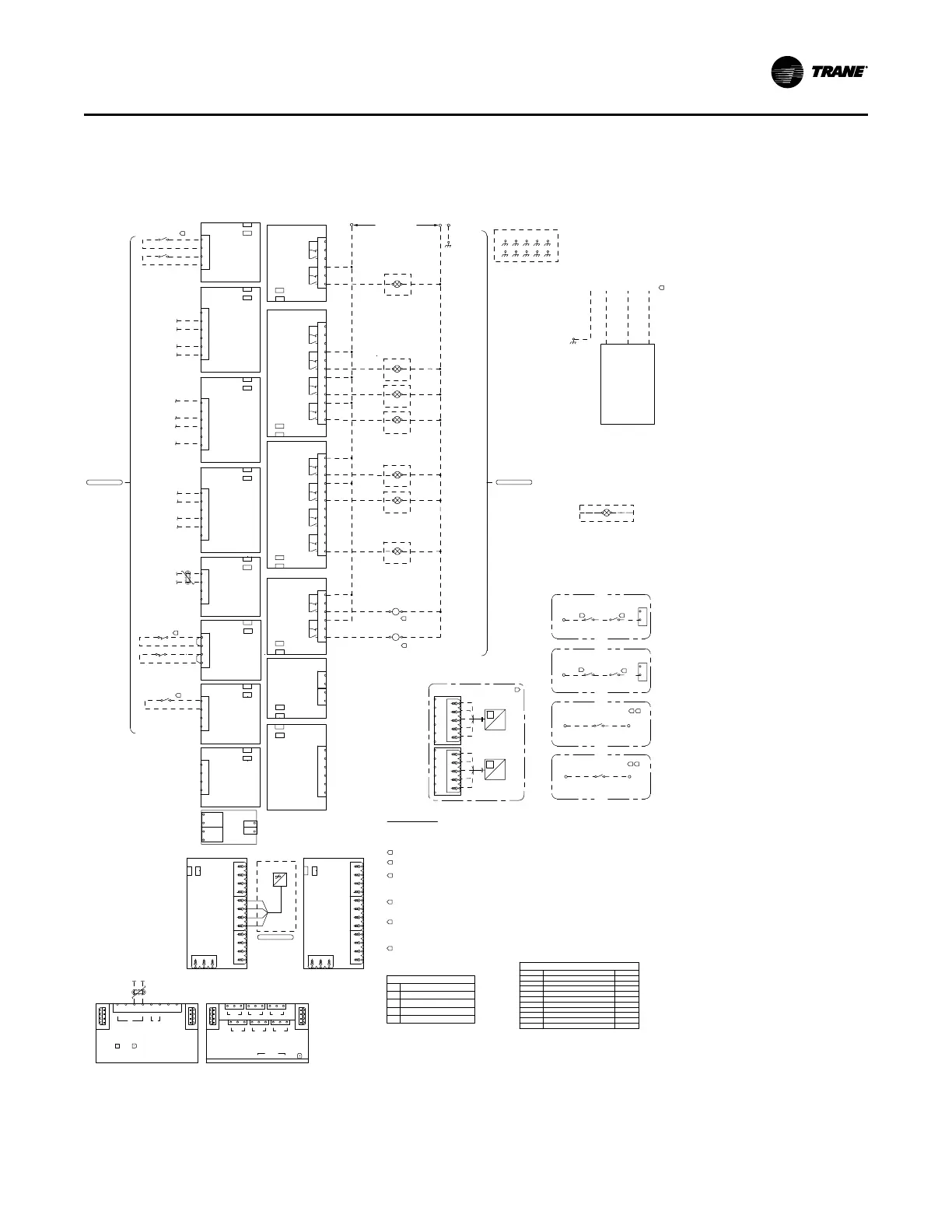

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

COM

NC

NO

COM

NC

NO

COM

NC

NO

11

GND

A B

LON

GND

-

+

LINK 1

GND

-

+

LINK 2

GND

A B

LON

GND

-

+

LINK 1

GND

-

+

LINK 2

1 2

ETHERNET

B-CMIA-CMI

1

1

120VAC 60HZ

CUSTOMER PROVIDED

MAX OVERCURRENT PROTECTION 15A

NOTE: ANY 1K13 OR 1K14 DEFAULT OUTPUT MY BE REPROGRAMED

TO ANY ALTERNATE ALRAM/STATUS OUTPUT SH OWN BELOW.

DUAL HIGH VOLTAGE BINARY INPUT

CONDENSER & EVAPORATOR

WATER FLOW DETECTION

SEE DET AILS D & E FOR

EVAPORATOR & CONDENSER

WATER FLOW SWIT CH &

WATER PUMP INTERLOCK

SERVICE

TOOL

CHILLER HEAD RELIEF

REQUEST INDICATOR

(DEFAULT)

CHILLER MAXIMUM

CAPACITY INDICAT OR

(DEFAULT)

CHILLER RUNNING

INDICATOR

(DEFAULT)

CHILLER LATCHING

ALARM INDICATOR

(DEFAULT)

CHILLER NON-LAT CHING

ALARM INDICATOR

(DEFAULT)

2-10VDC or 4-20mA

EXTERNAL BASE

LOADING SET POINT

2-10VDC or 4-20mA

GENERIC R EFRIGERANT

MONITOR INPUT

2-10VDC or 4-20mA

EXTERNAL CURRENT

LIMIT SETPO INT

2-10VDC or 4-20mA

EXTERNAL CHILLED

WATER SETPOINT

2-10VDC

% RLA COMPRESSOR

OUTPUT

2-10VDC

CONDENSER

REFRIGERANT

PRESSURE

or

EVAPORATOR/CONDENSER

DIFFERENTIAL PRESSURE

OUTPUT

TRACER

COMMUNICATIONS

-OPTIONAL-

QUAD R ELAY OUTPUT

OPERATING STATUS PR OGRAMMABLE

1K14

J2

2

1

3

4

5

6

7

8

9

10

11

12

J11

J1

-OPTIONAL-

QUAD R ELAY OUTPUT

OPERATING STATUS PR OGRAMMABLE

1K13

J2

2

1

3

4

5

6

7

8

9

10

11

12

J11

J1

5H10

1 2

5H11

1 2

5H6

1 2

5H1

1 2

5H2

1 2

-OPTIONAL-

DUAL LOW VOLT AGE BINARY INPUT

1K9

J2

2

1

3

4

J1

J11

-OPTIONAL-

DUAL ANALOG I/O

1K8

GND

INPUT 2

OUTPUT 2

GND

INPUT 1

OUTPUT 1

J2

2

1

3

4

5

6

J1

J11

-OPTIONAL-

DUAL ANALOG I/O

1K6

GND

INPUT 2

OUTPUT 2

GND

INPUT 1

OUTPUT 1

J2

2

1

3

4

5

6

J1

J11

-OPTIONAL-

DUAL ANALOG I/O

1K7

GND

INPUT 2

OUTPUT 2

GND

INPUT 1

OUTPUT 1

J2

2

1

3

4

5

6

J1

J11

5S5

2 1

5S6

2 1

EXTERNAL

BASE LOADING

ENABLED/DISABLED

EXTERNAL

HOT WATER

CONTROL

ENABLED/DISABLED

-OPTIONAL-

-OPTIONAL-

-OPTIONAL-

-OPTIONAL-

-OPTIONAL-

-OPTIONAL-

-OPTIONAL-

CHILLER LIMIT

MODE INDICAT OR

(ALTERNATE)

5H15

1 2

-OPTIONAL-

N DNG

H

1X1-G

5H7

1 2

-OPTIONAL-

CHILLER LIMIT

MODE INDICAT OR

(DEFAULT)

ICE BUILDING

INDICATOR

5H8

1 2

1K15

DUAL RELAY OUTPUT

J2

2

1

3

4

5

6

J11

J1

1W2

1W3

EXTERNAL AUT O STOP

EMERGENCY STOP

REMOVE JUMPERS 1W2 AND 1W3

IF DEVICES ARE PRESENT

DUAL LOW VOLT AGE BINARY INPUT

1K4

J2

2

1

3

4

J1

J11

5S3

5S4

-OPTIONAL-

LONTALK LCI-C MODULE

1K5

J2

2

1

3

4

J1

J11

CONDENSER

WATER PUMP

CONTROL

EVAPORATOR

WATER PUMP

CONTROL

5K1

2 1

5K2

2 1

4

4

1K12

DUAL RELAY OUTPUT

J2

2

1

3

4

5

6

J11

J1

1K11

J2

2

1

J3

2

1

J11

J1

POWER SUPPLY 1

1T1

J2

1 2 3

J5

1

2

3

4

J4

1

2

3

4

J3

1

2

3

4

J11

J1

POWER SUPPLY 1

1T2

J2

1 2 3

J5

1

2

3

4

J4

1

2

3

4

J3

1

2

3

4

J11

J1

1K21

UC800 UNIT

CONTROLLER

+24 VDC

GND

+

-

+

-

+

-

M

BU

S

LINK

IM

C

-

B

IMC-A

S

E

RVICE TOOL

ETHERNET

2

1

3

4

5

6

7

8

CUSTOMER GROUND

DUAL LOW VOLT AGE BINARY INPUT

1K3

J2

2

1

3

4

J1

J11

5S7

2 1

EXTERNAL ICE

BUILDING

COMMAND

-OPTIONAL-

HI-TEMP SENSO R

TRIPLE W INDING INPUT

1K2

J2

2

1

3

4

J1

J11

1K1

TACH BOARD

J1-2(0V)

J1-1(24VDC)

J3-1(TTL+)

J2-1

J2-2

J3-2(TTL-)

-OPTIONAL-

DUAL ANALOG I/O

1K10

GND

INPUT 2

OUTPUT 2

GND

INPUT 1

OUTPUT 1

J2

2

1

3

4

5

6

J1

J11

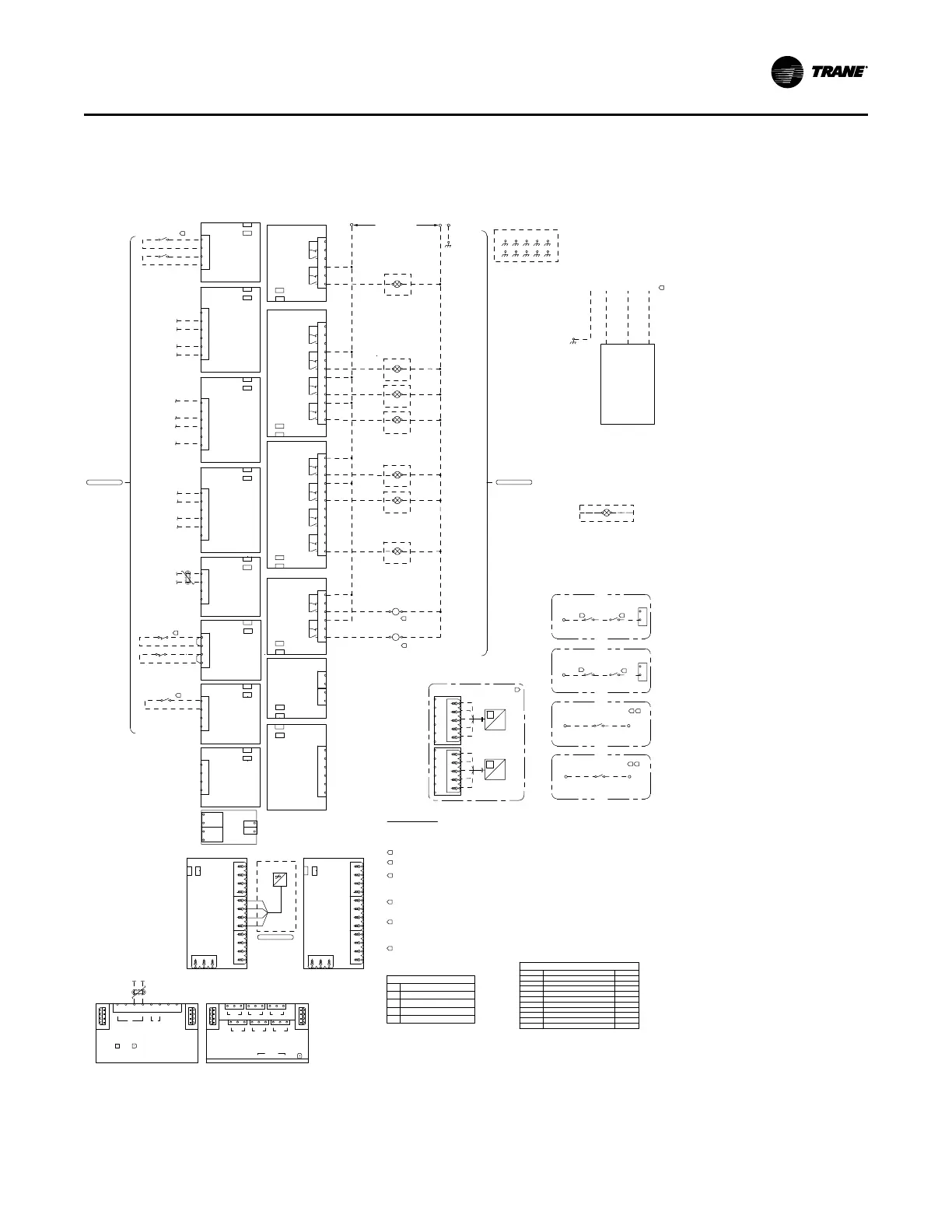

WHT

BLU

BRN

BLK

GRY

WB11 WB12

WHT

BLU

BRN

BLK

GRY

EVAPORATOR

WATER FLOW

DETECTOR

(FIELD INSTALLED)

CONDENSER

WATER FLOW

DETECTOR

(FIELD INSTALLED)

Pd

4R17

Pd

4R18

1K23

5 7 8 4 1 2

17 18 19 20 21

1K22

5 7 8 4 1 2

17 18 19 20 21

1K11

2

1

220U 162A

J2

PRIMARY

REQUIRED

5S12

1 2

5S18

1 2

162A

OR

163A

SECONDARY

OPTIONAL

5

6

1K11

2

1

220V

J3

PRIMARY

REQUIRED

5S11

1 2

160A

OR

161A

160A

5

CUSTOMER SUPPLIED CONDENSER

PROOF O F FLOW DEVICES

CUSTOMER SUPPLIED EVAPORATOR

PROOF O F FLOW DEVICES

INSET D

INSET D

INSET E

INSET E

5S17

1 2

220G

4-22K1OT3-1X1OT

4-32K1OT2-1X1OT

TO 1X1-2

TO 1X1-3

SECONDARY EVAPORAT OR W ATER

PROOF O F FLOW DEVICES

INSET F

INSET F

5S17

1 2

158A

220E

5S18

1 2

159A

7

SECONDARY CONDENSER W ATER

PROOF O F FLOW DEVICES

INSET G

INSET G

SECONDARY

OPTIONAL

6

7 6

6

OPTIONAL BACNET

OR MODBUS

1K20

-OPTIONAL-

CLASS 2 WIRING

CLASS 1 WIRING

-OPTIONAL-

L1 L2 L3

2Q1

CUSTOMER PROVIDED

LINE VOLTAGE

(SEE UNIT NAMEPLATE)

L1

L2

L3

GND

-SEE INSET D,E,F,G-

5

FLAG NOTES

1. CAUTIO N-DO NOT ENERGIZE THE UNIT UNTIL CHECK O UT AND STARTUP PROCEDURES HAVE BEEN COMPLETED.

2. CAUTIO N-TRANE PUMP CONTROL MUST BE USED TO PROVIDE PUMP CONTROL. EVAPORAT OR CHILLED WATER PUMP MUST

BE CONT ROLLED BY THE CHILLER OUTPUT. FAILURE T O COMPLY WITH THIS R EQUIREMENT MAY RESULT IN DAMAGE OT THE UNIT.

3. RECOMMENDED FIELD W IRING CONNECTIONS AR E SHOW N BY DASHED LINES

4. UNIT PROVIDED DRY CONTACT S FOR WATER PUMP CONTROL.RELAY RATING AT 120VAC: 7.2 AMPS RESISTIVE, 2.88 AMPS PILOT DUTY,

1/3 HP, 7.2 FLA RELAY RATING AT 240VAC: 5 AMPS GENERAL PURPOSE.

5. INSTALLATION OF PRIMARY EVAPORATOR AND CONDENSER W ATER PROOF OF FLOW DEVICES ARE REQUIRED. THESE ARE INDICATE

AS 5S11 AND 5S12 CUSTOMER SUPPLIED DEVICES AND MUST BE A FLOW SENSING DEVICE SUCH AS A FLOW SW ITCH, W ATER FLOW DETECTION

CONTROLLER OR A DIFFERENTIAL PRESSU RE SW ITCH. SEE INSET D AND E FOR INSTALLATION.

6. PRIMARY EVAPORATOR AND CONDENSER WATER PROOF OF FLOW IS ALSO SHO WN USING OPT IONAL TRANE INSTALLED 1K22 AND 1K23 W ATER FLOW

DETECTION CONTROLLERS. 4R17 AND 4R18 WAT ER FLOW DETEC TION SENSORS AND WB11 AND W B12 CABLES ARE SUPPLIED BY TR ANE FOR FIELD

INSTALLATION BY THE CUSTOMER.

INSTALLATION OF CUSTOMER SUPPLIED SECO NDARY EVAPORATOR AND CONDENSER W ATER PROOF OF FLOW DEVICES AR E AT THE DISCRETION O F

THE CUSTOMER. THESE ARE INDICATED AS 5S17 AND 5S18 AND MAY BE A W ATER PUMP INTERLOCK, VALVE END SW ITCH O R ANY OTHER PRO OF OF FLOW DEVICE.

TRANE RECOMMENDS INSTALLATION OF T HE 5S17 SECONDARY EVAPORATO R W ATER PROOF OF FLOW DEVICE W HEN THE LEAVING WAT ER TEMPERATURE IS

EXPECTED T O BE 38°F OR LESS AND THAT THE METHOD USED IS INDEPENDENT OF THE PRIMARY W ATER PROOF OF FLOW DEVICE TO PROVIDE REDUNDANCY.

7. IF OPTIONAL TRANE INSTALLED 1K22 AND/OR 1K23 W ATER FLOW DETECTION CONTROLLERS AR E USED AND T HE CUSTO MER CHOOSES TO INSTALL 5S17 AND/OR

5S18 SECONDARY PROOF OF FLOW DEVICES THEN T HE CUSTOMER MUST REMOVE TRANE FACTORY WIRE BETWEEN 1X1-2 AND 1K23-4 AND/OR WIRE BETWEEN 1X1-3

AND 1K22-4. SECONDARY DEVICES WOULD THEN BE INSTALLED AS SH OWN IN INSET G AND/OR F.

TRANE RECOMMENDS W IRING THE 5K1 EVAPORATOR AND 5K2 CO NDENSER W ATER PUMP CONTROL RELAYS AS SHOWN TO ALLOW THE 1K15 MODULE T O CONT ROL

PROPER SEQ UENCING.

8. ALL UNIT POWER WIRING MUST BE 600 VOLT COPPER CONDUCTORS ONLY. REFER TO UNIT NAMEPLATE FOR MINIMUM CIRCUIT AMPACITY AND MAXIMUM

OVERCURRENT PROTECTION DEVICE. PROVIDE AN EQ UIPMENT GROUND IN ACCORDANCE W ITH APPLICABLE ELECTRIC CODES. REFER TO WIRERANGE TABLE FOR LUG SIZES.

9. ALL FIELD W IRING MUST BE IN ACCORDANCE W ITH NATIO NAL ELECTRIC CODE AND LOCAL REQUIREMENTS.

10. ALL CUSTOMER CO NTROL CIRCUIT W IRING MUST BE COPPER CONDUCT ORS ONLY AND HAVE A MINIMUM INSULATION RATING OF 300 VOLTS. EXCEPT AS NOTED, ALL CUST OMER

WIRING CONNECTIONS ARE MADE TO CIRCUIT BOARD MOUNTED BOX LUGS WITH A WIRE RANGE OF 14 T O 18 AWG OR DIN RAIL MOUNTED SPRING FORCE TERMINALS.

11. CUSTOMER SUPPLIED CONTACTS FOR ALL LOW VOLTAGE CONNEC TIONS MUST BE COMPATABLE W ITH DRY CIRCUIT 24 VOLTS DC FOR A 12 mA RESISTIVE

LOAD. SILVER OR GOLD PLATED CONTACTS RECOMMENDED.

4BT9

GRY

BLU

BLK

RED

OUTDOOR AIR

TEMPERATURE SENSOR

-OPTIONAL-

CLASS 2 WIRING

8

11

11

11

1

2

3

4

5

CONTROL PANEL

DRIVE PANEL

NOT USED

UNIT MOUNTED DEVICE

CUSTOMER PROVIDED DEVICE

DEVICE PREFIX LOCATION CODES

FUSE REPLACEMENT TABLE

DEVICE ID FUSE TYPE FUSE SIZE

2F1

2F2

2F3

2F4

2F5

2F6

2F7

2F8

2F11

2F12

CLASS CC

CLASS CC

CLASS CC

CLASS CC

CLASS CC

CLASS CC

CLASS CC

CLASS CC

BUSSMANN - 170M3467

BUSSMANN - 170M3467

15A

15A

10A

10A

5A

15A

5A

20A

315A

315A

Loading...

Loading...