HDWA-SVX001D-EN

65

the refrigerant condensing temperature and the leaving

condenser water temperature) is higher than predicted.

Condenser tube fouling is indicated when the approach

temperature (the difference between the condensing

refrigerant temperature and the leaving condenser

water temperature) is higher than predicted. Refer to

sales order selection data for approach temperatures.

NNoottee:: Glycol in the water system typically doubles the

standard approach.

If the annual condenser tube inspection indicates that

the tubes are fouled, two cleaning methods

(mechanical or chemical) can be used to rid the tubes

of contaminants. The methods are described in the

following sections.

Mechanical Cleaning

Mechanical tube cleaning is used to remove sludge and

loose material from smooth-bore condenser tubes.

WWAARRNNIINNGG

HHeeaavvyy OObbjjeeccttss!!

FFaaiilluurree ttoo pprrooppeerrllyy lliifftt wwaatteerrbbooxx ccoouulldd rreessuulltt iinn

ddeeaatthh oorr sseerriioouuss iinnjjuurryy..

EEaacchh ooff tthhee iinnddiivviidduuaall ccaabblleess ((cchhaaiinnss oorr sslliinnggss))

uusseedd ttoo lliifftt tthhee wwaatteerrbbooxx mmuusstt bbee ccaappaabbllee ooff

ssuuppppoorrttiinngg tthhee eennttiirree wweeiigghhtt ooff tthhee wwaatteerrbbooxx.. TThhee

ccaabblleess ((cchhaaiinnss oorr sslliinnggss)) mmuusstt bbee rraatteedd ffoorr

oovveerrhheeaadd lliiffttiinngg aapppplliiccaattiioonnss wwiitthh aann aacccceeppttaabbllee

wwoorrkkiinngg llooaadd lliimmiitt.. RReeffeerr ttoo tthhee ttaabbllee ffoorr wwaatteerrbbooxx

wweeiigghhttss..

Waterbox Removal

Review mechanical room limitations and determine the

safest method or methods of rigging and lifting the

waterboxes.

IImmppoorrttaanntt::

• Do NOT rotate waterboxes.

• Be sure to replace water boxes right-

side-up to maintain proper baffle

orientation. Use new O-rings.

• if the waterbox is reversed, be sure to

match mark on the baffle and waterbox

to ensure that they are aligned.

1. Determine the size of chiller being serviced. See

unit nameplate located on chiller control panel.

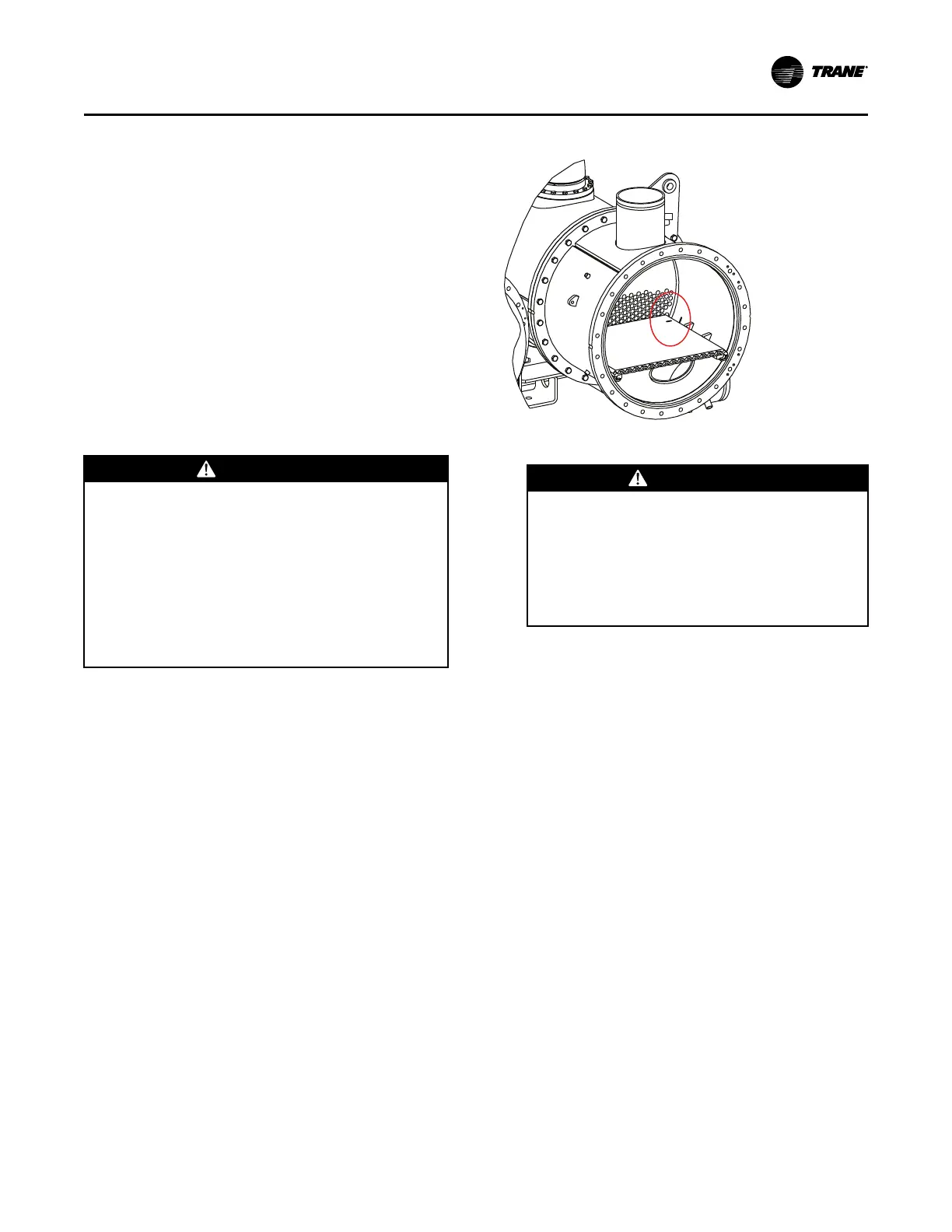

2. Use a 3/8-in. (9.5-mm) rigging shackle for waterbox

removal as shown in the following figure. The rated

lifting capacity of the selected lift connection device

must meet or exceed the published weight of the

waterbox. Refer to the tables in “Waterbox

Reassembly,” p. 66.

3. Install rigging shackle onto the lifting connection on

the waterbox.

4. Disconnect water pipes, if connected.

5. Match mark on the waterbox and the baffle to

ensure that they are aligned.

6. Remove waterbox bolts.

WWAARRNNIINNGG

OOvveerrhheeaadd HHaazzaarrdd!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss ccoouulldd rreessuulltt iinn

ddeeaatthh oorr sseerriioouuss iinnjjuurriieess..

NNeevveerr ssttaanndd bbeellooww oorr iinn cclloossee pprrooxxiimmiittyy ttoo

hheeaavvyy oobbjjeeccttss wwhhiillee tthheeyy aarree ssuussppeennddeedd ffrroomm,,

oorr bbeeiinngg lliifftteedd bbyy,, aa lliiffttiinngg ddeevviiccee iinn ccaassee tthhee

oobbjjeecctt ddrrooppss..

7. Lift the waterbox away from the shell.

8. Store the waterbox in a safe and secure location

and position.

9. Work a round nylon or brass bristled brush

(attached to a rod) in and out of each of the

condenser water tubes to loosen the sludge.

10. Thoroughly flush the condenser water tubes with

clean water.

NNoottee:: To clean internally enhanced tubes, use a bi-

directional brush or consult a qualified

service organization for recommendations.

MMaaiinntteennaannccee

Loading...

Loading...