Installation

CDUB-SVN001B-EN 25

Mount transducers on the entering and leaving side water

box locations with the transducer facing upwards and

connect to unit control buss. After system is filled, loosen

the transducer in its threaded fitting. Then crack the

isolation valve until water starts dripping from threads.

Close the valve and re-tighten the transducer, and then re-

open the valve for use.

High Accuracy Customer Meter Option

The high accuracy customer meter option provides an

analog input/output LLID to monitor a customer provided

high accuracy meter 0-10 Vdc or 4 – 20 mA outputs.

(Rosemont, etc.) This option allows monitoring of

condenser, evaporator flow and auxiliary heat

exchangers.

Install needed DAIO LLID(

s) (BRD04875) in CVRF control

panel:

1. LLID (1A21) is needed for EVAP and COND water flow.

Conne

ct flow meter wires to 1A21-J2-1 and 1A21-J2-1

for EVAP, 1A21-J2-4 and 1A21-J2-5 for COND.

2. LLID (1A28) is need for HR Aux/COND water

flow.

Conne

ct flow meter wires 1A28-J2-1 and 1A28-J2-1 for

HR flow or Aux COND.

Heat Recovery/Aux COND Option

When heat recovery/Aux COND option is selected, a

DHVBI LLID (BRD04874) is required as 1A29 and wires

matrix show as following:

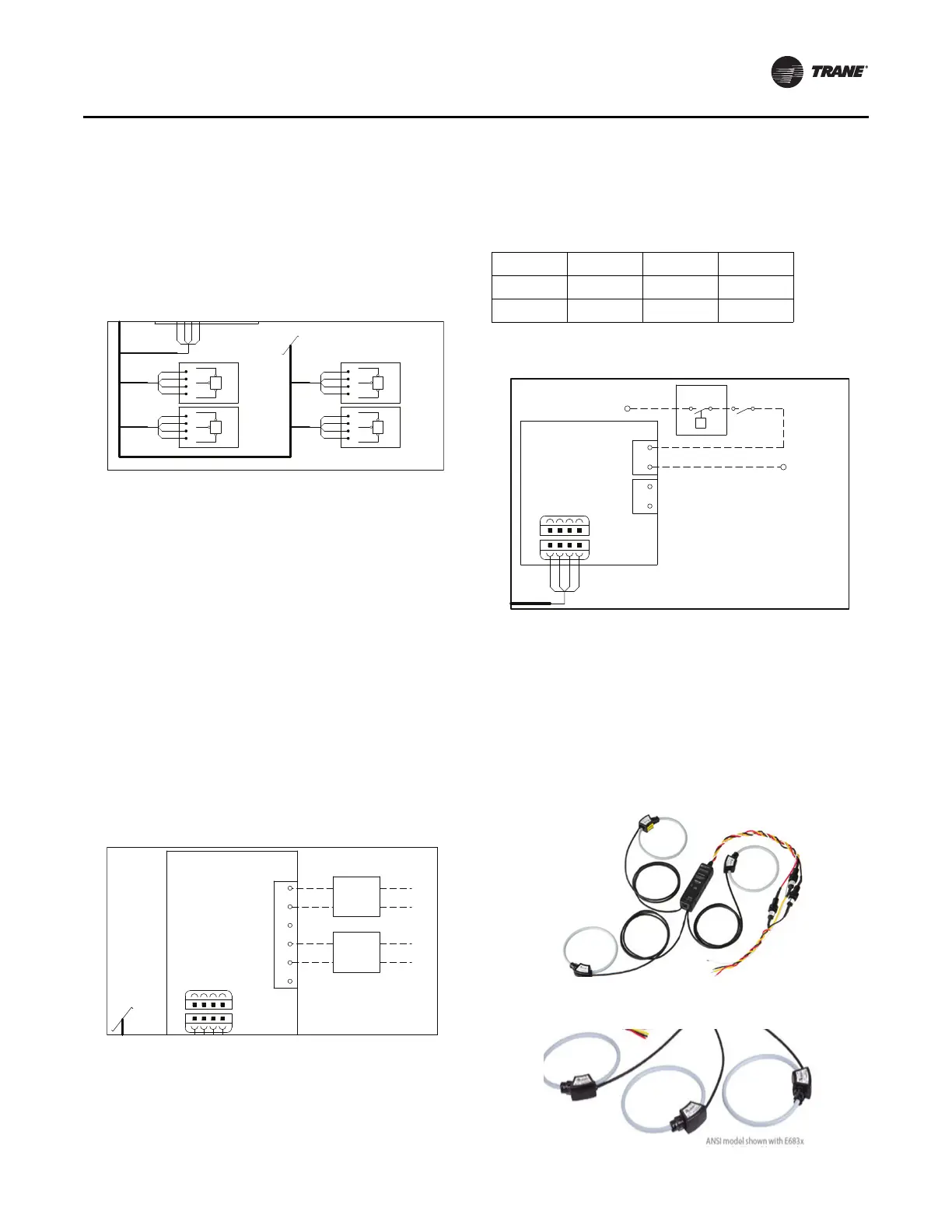

Energy Meter Option Installation

The Trane energy meter provides instrument grade

accuracy power, volts and amps monitoring of Symbio

controls installations. It has 1% accuracy for measuring

both real power and energy and reactive power and

energy. All data measured by the meter is communicated

via Modbus to Symbio control system. For more detail

information, refer to BAS-SVN224*-EN.

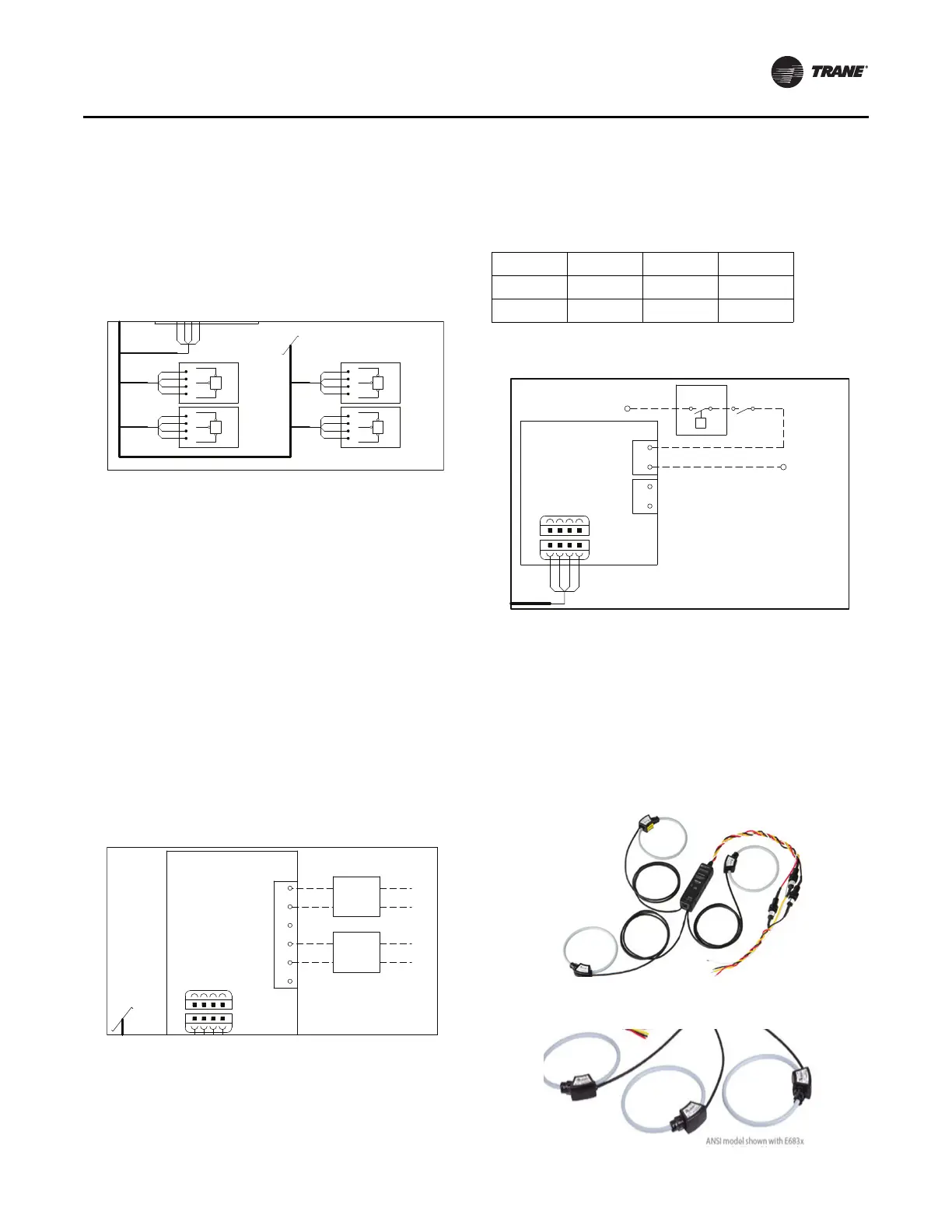

Figure 47. Standard accuracy flow meter wiring,

ref.

50712792

Figure 48. High accuracy customer meter flow meter

wiring, ref. 50712792

WATER PRESSURE

EVAP ENTERING

OPTIONAL

TRANSDUCER

WATER PRESSURE

EVAP LEAVING

OPTIONAL

TRANSDUCER

WATER PRESSURE

COND ENTERING

OPTIONAL

TRANSDUCER

WATER PRESSURE

COND LEAVING

OPTIONAL

TRANSDUCER

IPC BUS

FLOW METER

RED

-

Pg

+

SIG

4BP4

-

Pg

+

SIG

4BP5

-

Pg

+

SIG

4BP6

-

Pg

+

SIG

4BP7

1A21 DUAL ANALOG I/O

OPTIONAL

INPUT 1

OUTPUT 1

2

1

GND

INPUT 2

OUTPUT 2

GND

4

3

J2

5

6

COND FLOW METER

5B2 CUSTOMER PROVIDE

4-20mA

FLOW

METER

OUTPUT

EVAP FLOW METER

5B1 CUSTOMER PROVIDE

SIGNAL

24VDC

1A2 J3-1

0V

4-20mA

FLOW

METER

24VDC

1A1 J3-1

0V

1A2 J3-2

1A1 J3-2

OUTPUT

SIGNAL

IPC BUS

4

4

J11

1

J1

1

OPTIONAL WATER FLOW METER

CUSTOMER PROVIDE 4-20MA INPUT

Table 3. Wire matrix

Wire # AWG From To

14B 16 1A29-J3-2 1X1-21

2K 16 1A29-J3-1 1X2-10

Figure 49. Heat recovery/Aux COND flow switch wiring

Figure 50. Energy meter

Figure 51. Rogowski CTs

1X1-15

d

P

5S11 5K3

REQUIRED OPTIONAL

AUX CONDENSER

WATER FLOW SWITCH

HEAT RECOVERY

1X1-7

1A29 DUAL HIGH VOLTAGE BINARY INPUT

4

4

1

2

1

J2

RED

J11

J1

1

1

J3

2

WATER FLOW SWITCH

AUX CONDENSER

HEAT RECOVERY

OPTIONAL

Loading...

Loading...