TrojanTwo User Guide v3.8

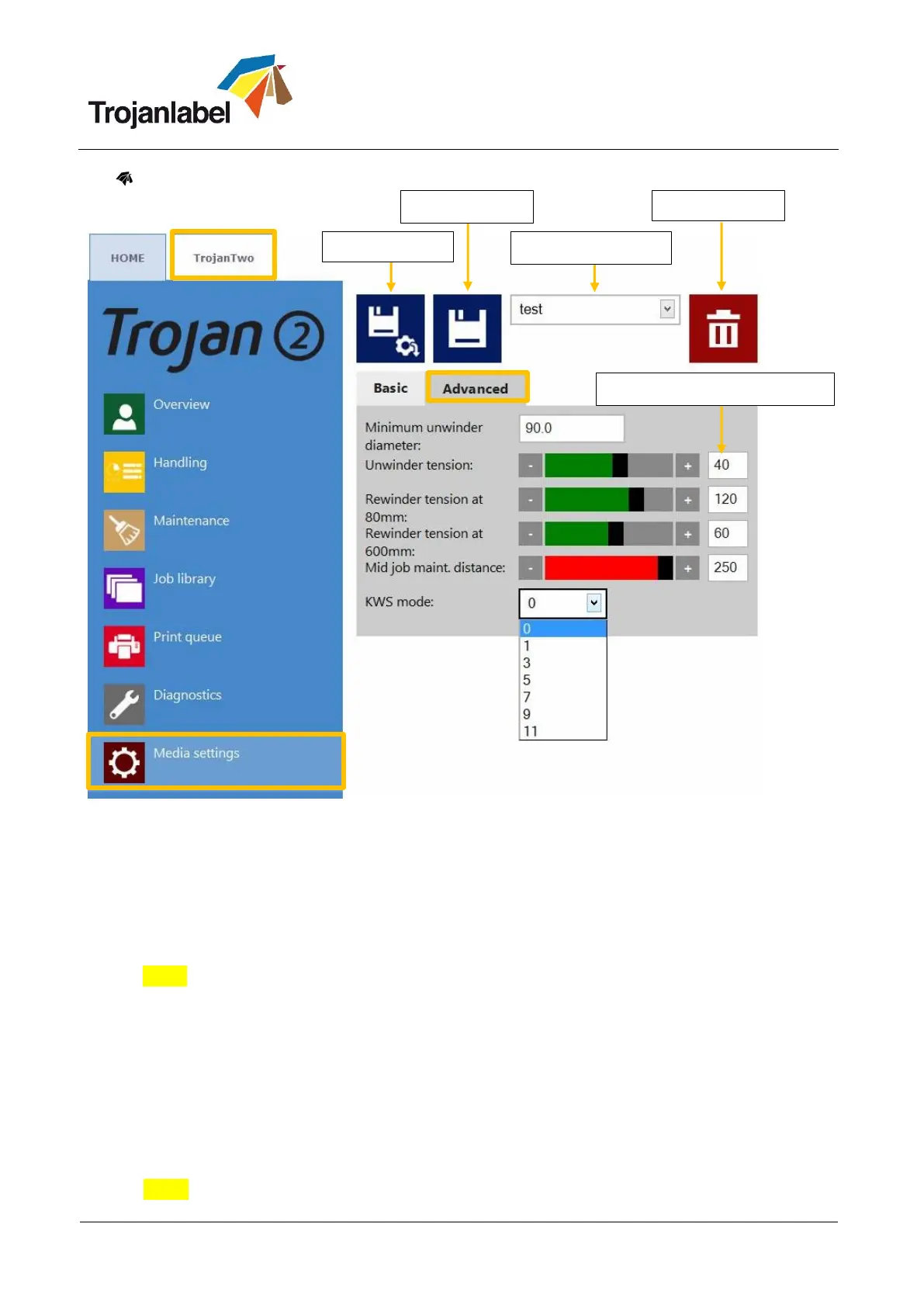

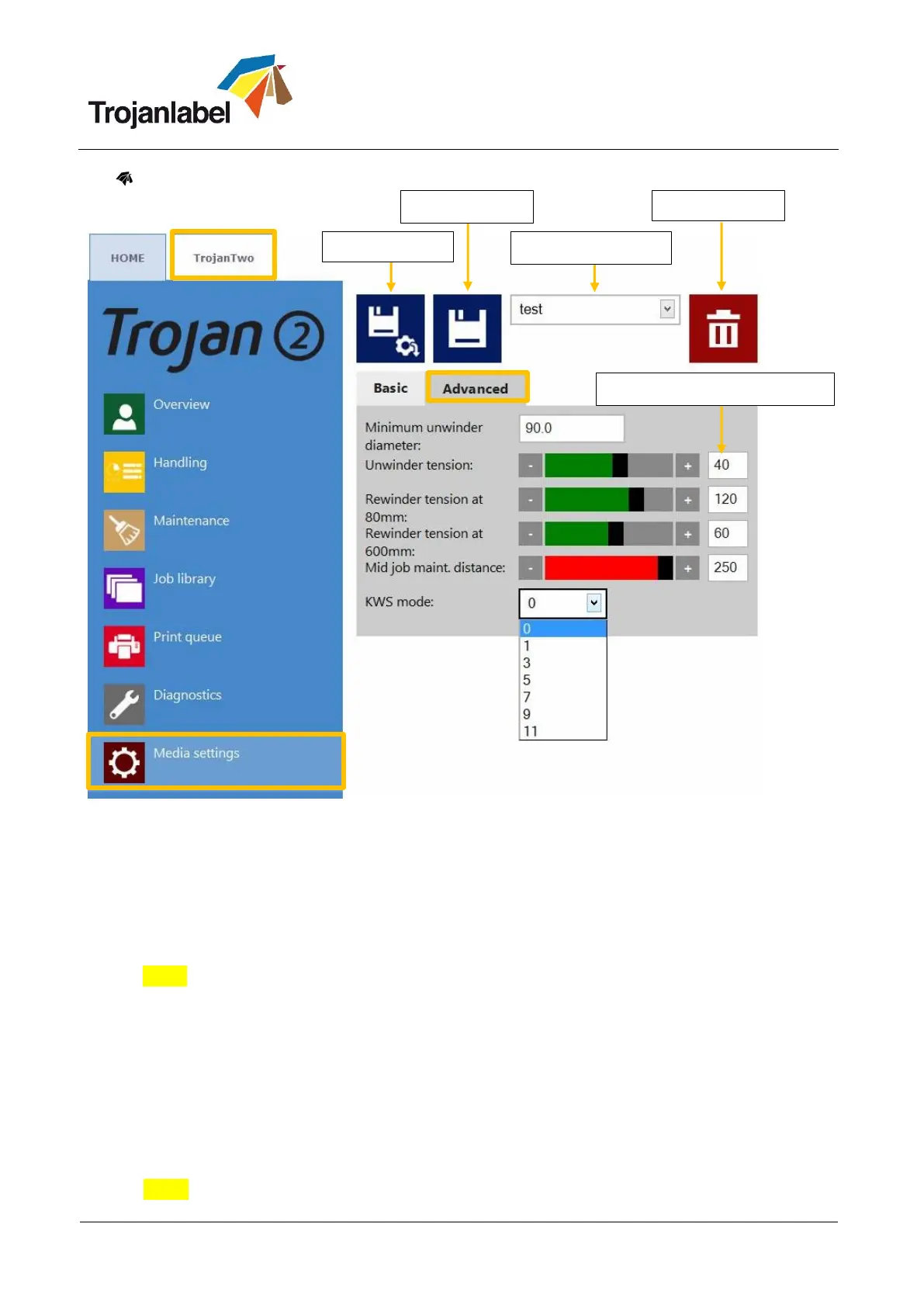

Media Settings Advanced:

KWS mode: KWS = Keep Wet Spitting

KWS is a function to protect the 70,400 printhead nozzles from dehydration. In practice it means

that during printing all the nozzles fire some ink, even the nozzles which do not take part effectively

in printing. As a result tiny (almost microscopic) dark spots of ink might be seen on printouts,

especially when the background of the printed image is light in color. When those tiny spots are not

acceptable from the print quality point of view, this function can be reduced or switched off

completely.

NOTE: See KWS levels on next page more detailed

Minimum unwinder diameter (mm): When roll diameter reaches the minimum unwinder diameter

value, the printing will be paused and new label roll can be loaded and spliced. This sensor setting

is to avoid running out from labels during a print job.

Unwinder tension: adjusting unwinder tension.

Rewinder tension at 80mm roll diameter: adjusting rewinder tension for the beginning of a roll up.

Rewinder tension at 600mm roll diameter: adjusting rewinder tension for the end of a roll up.

Mid job maint. Distance (meter): Setting mid-job maintenance frequency in printed linear meters.

Mid-job maintenance is a full printhead maintenance during processing a print job to preserve best

print quality.

NOTE: Actual value is always displayed at status bar on the screen

Recommended tension values

Loading...

Loading...