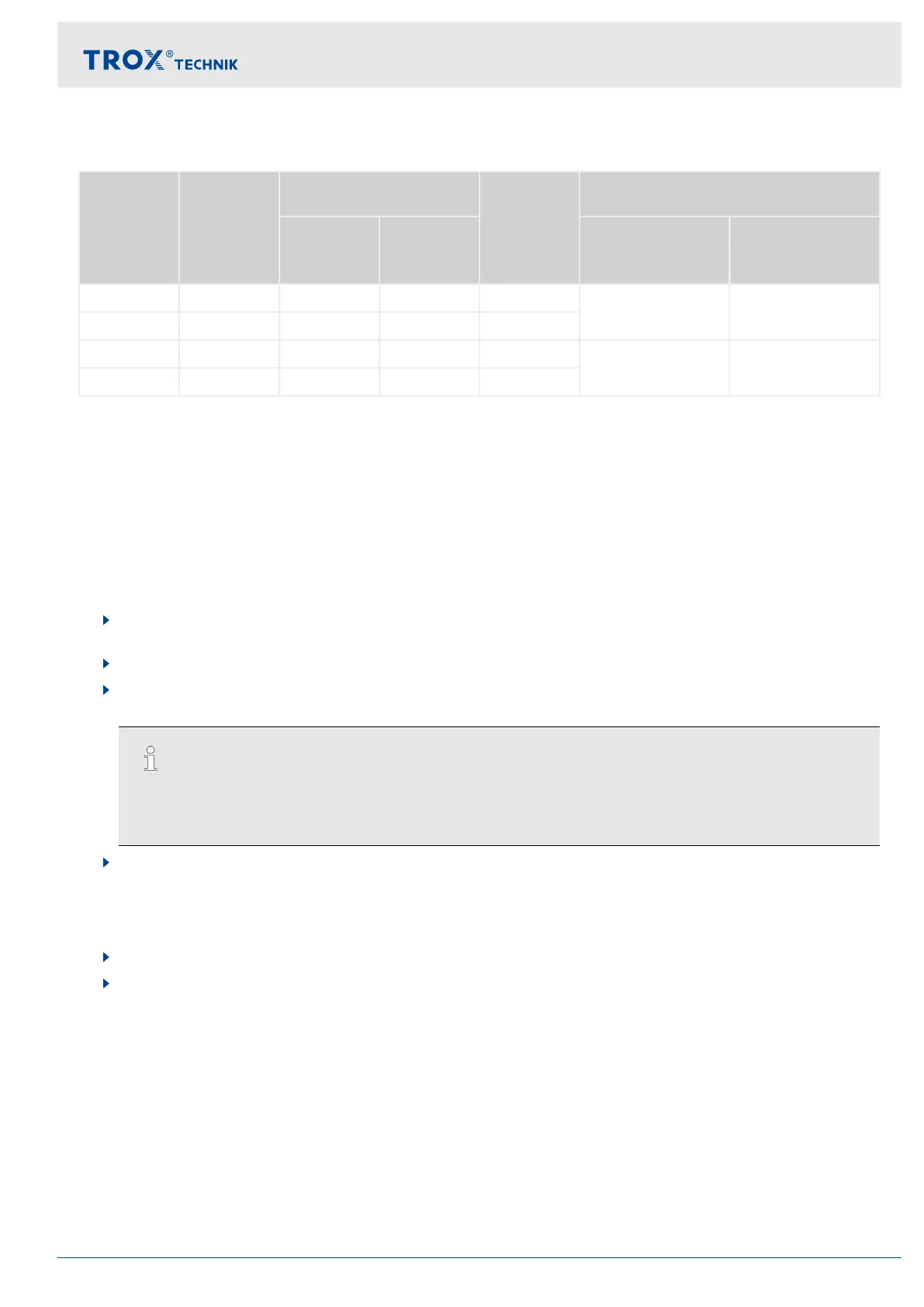

Performance class and installation details

Perform-

ance class

Fire batt Casing construction /

∅DN [mm]

Distance to

load-

bearing

structural

elements

[mm]

Distance between two fire dampers

[mm]

Galvanised

steel

Stainless

steel

Two installation

openings

One installation

opening (flange to

flange)

EI 120 S HENSEL 100...200 – ≥75 ≥200 –

EI 120 S Hilti 100...200 – ≥75

EI 90 S Hilti 100...315 100...200 ≥40 ≥200 a = 40...400

EI 90 S HENSEL 100...315 – ≥40

Personnel:

Specialist personnel

Materials:

Fire batt systems

Ä

‘Acceptable fire batt systems’ on page 14

Requirements

Performance class EI 120 S or EI 90 S

Ä

‘Performance class and installation details ’ Table on page 35

Lightweight partition walls with metal support structure and cladding on both sides, W ≥ 100 mm; detailed specifi-

cation

Ä

on page 27.

Duct connection with flexible connector (recommended)

1. Erect the lightweight partition wall according to the manufacturer's instructions and create an installation

opening

Ä

27.

2.

Push the fire damper into the wall opening and fix it with threaded rods

Ä

46.

3. Extend the fire damper on the installation side with an extension piece (either attachment or supplied by

others).

Note

The fire damper must have a fire protection coating (50 mm) on the installation side. The spigot of the fire

damper must not be coated. This is why the fire damper requires an extension piece on the installation

side; alternatively, the fire damper can be connected to the ductwork before the coating is applied.

4. Completely close off the perimeter gap between the fire damper and the wall or ceiling slab with two layers of

coated mineral wool slabs, ≥ 140 kg/m³. Apply fire protection sealant to the cut faces of the mineral wool slabs

and fit them tightly into the opening. Seal any gaps between the mineral wool slabs and the trim panels, gaps

between the cut faces of cut-to-size pieces, and gaps between slabs and the fire damper by applying fire pro-

tection sealant.

5. Apply fire protection coating to joints, transitions, and any imperfections on the pre-coated mineral wool slabs.

6. Apply fire protection coating, at least 2.5 mm thick, to the fire damper casing perimeter on both sides of the

wall or ceiling slab. The actuator and release unit must not be coated.

Installation

Lightweight partition walls > Dry mortarless installation with fire batt

Fire damper Type FKRS-EU 35

Loading...

Loading...