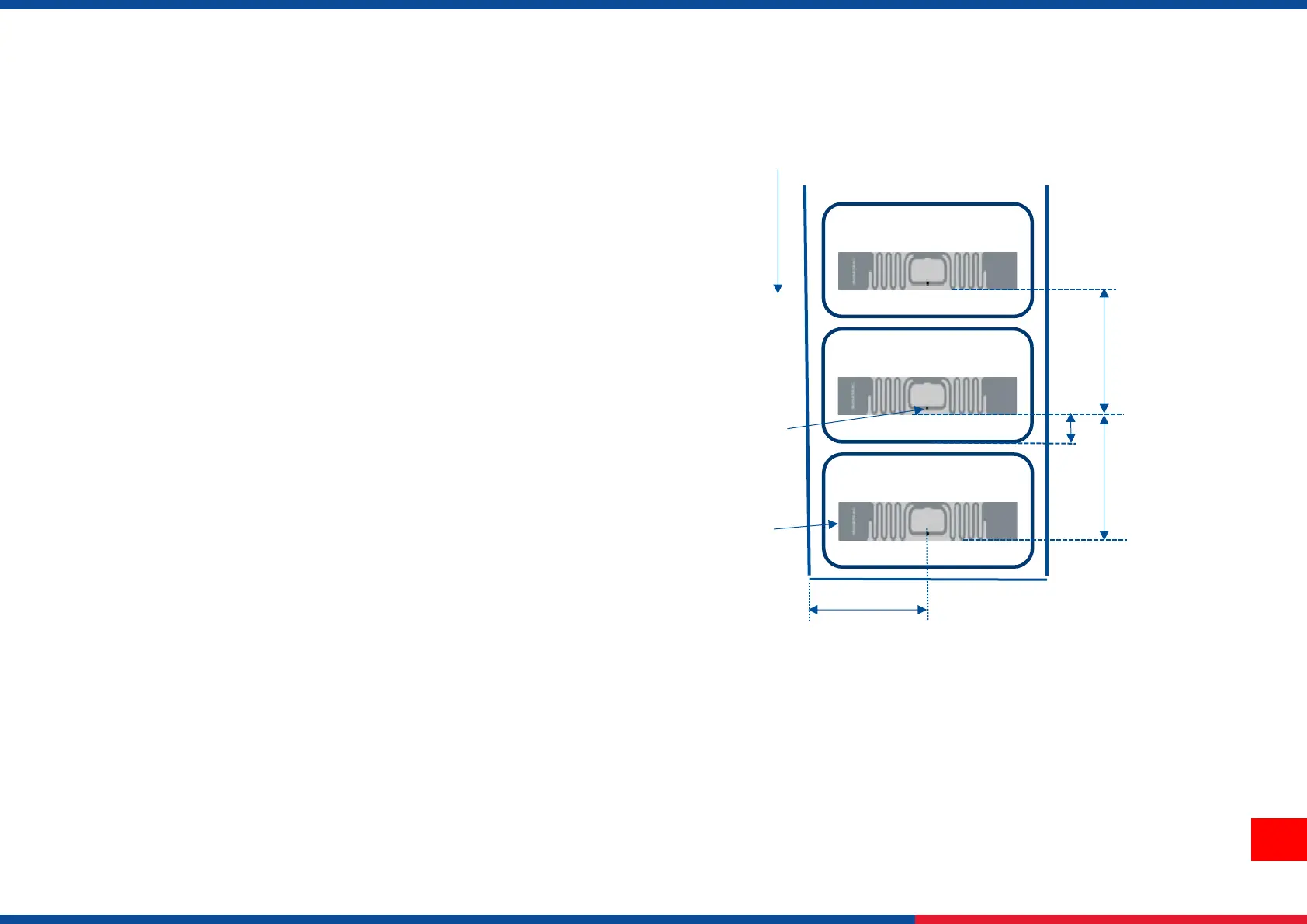

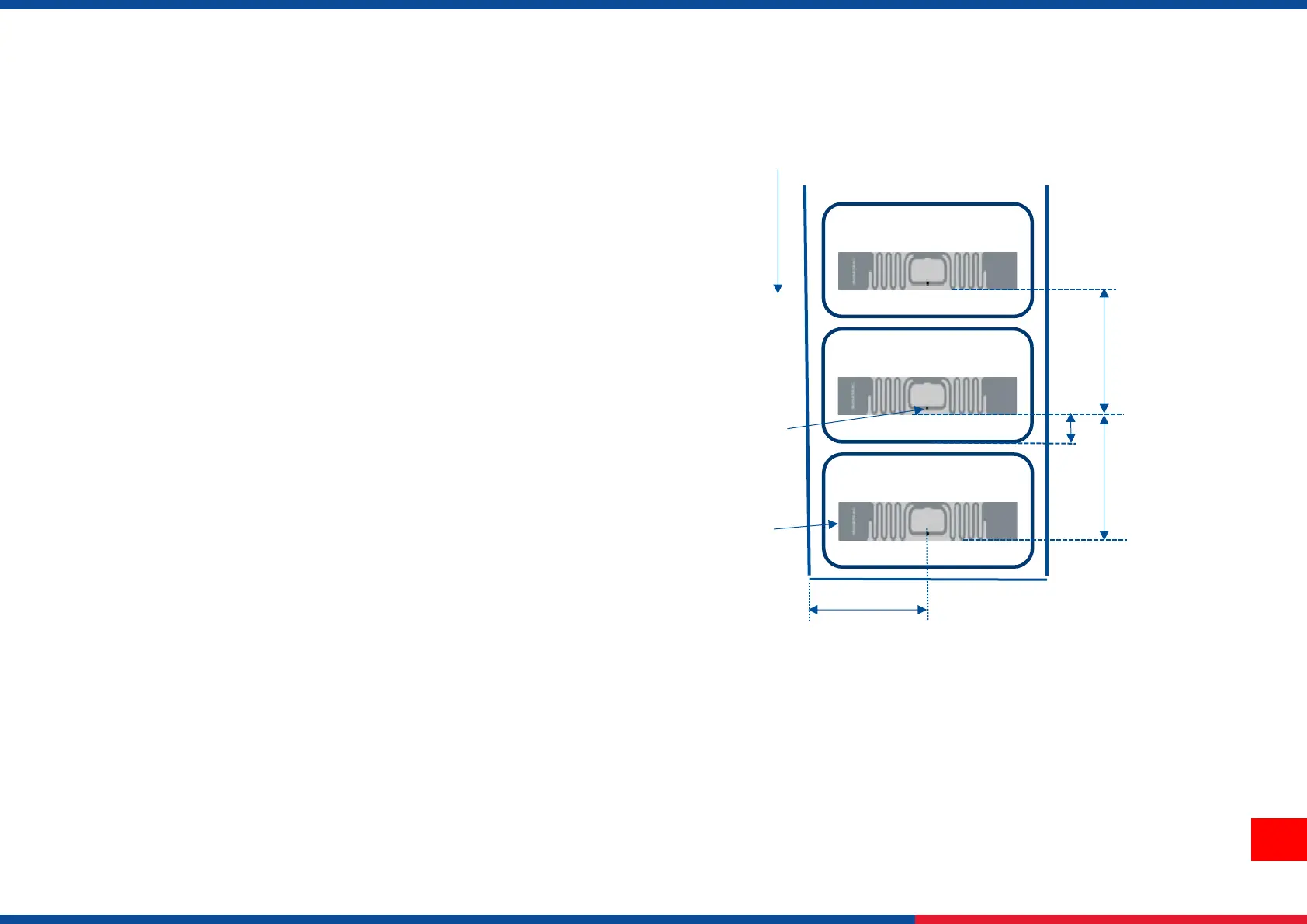

a: Center-Line

X: Lead Edge

P: Pitch

3.8.2 RFID Media Guideline for Alpha-40L(R)

Here are a few things to consider for optimum performance. (Referring to the diagram on the right)

IMPORTANT: Always test RFID media on your printer before purchasing large quantities of media.

◼ Inlays should be centered across the media width with

a production tolerance of less than +/- 2mm

(dimension "a"). Consistent, tag-to-tag placement of

the inlays is more important than how close to center

the inlays are actually placed.

◼ Only Direct thermal media are supported. Minimum

black bar size is 8 mm(w) x 2 mm(h) and position is

centered.

◼ Maximum roll OD is 62 mm (2.44”). Media should be

wound on 1”, 0.75” or 1.5” ID core.

◼ The pitch (overall distance from inlay to inlay) is shown

as dimension "P". Tags with pitch less than 1" may

require the printer to back-feed during the encoding

and printing process, thus slowing the throughput of

the printer. The pitch should be greater than 1", if

possible to avoid this condition.

◼ The inlay should be set back from the lead edge of the

media (dimension "X") a constant distance tag to tag.

The "X" distance should be more than 5 mm to prevent

pre-peel.

Loading...

Loading...